Adhesive composition, adhesive layer, surface protecting film and optical member

A surface protection film and adhesive layer technology, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of color change of the adhesive layer and achieve anti- Excellent electrostatic properties and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

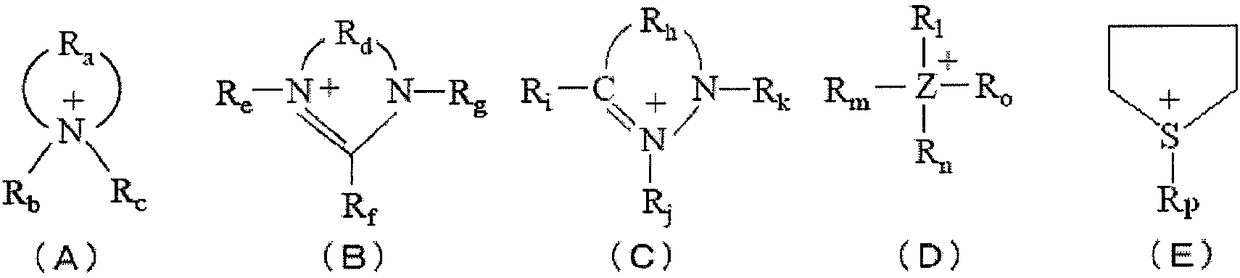

Method used

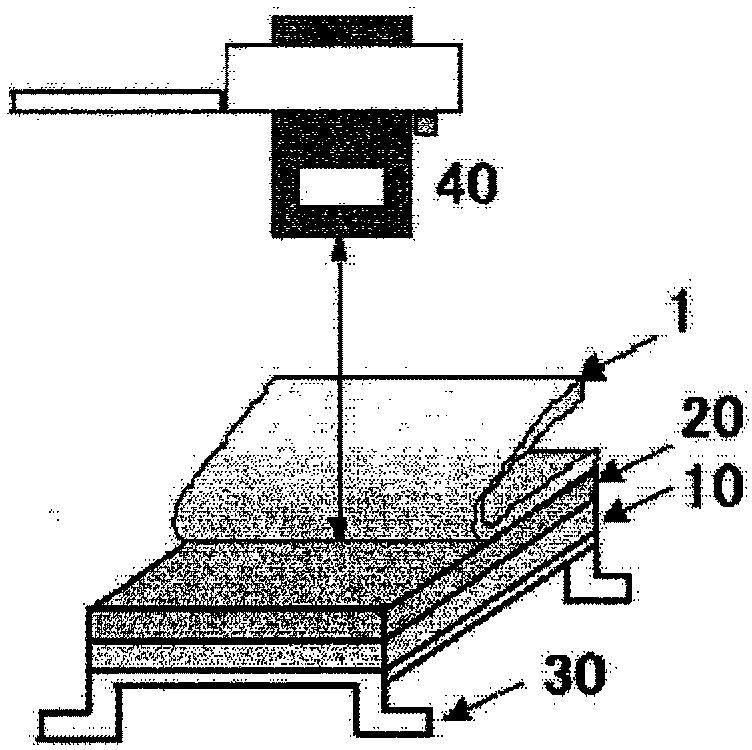

Image

Examples

Embodiment 1

[0216] [Preparation of Acrylic Binder Solution]

[0217] The above-mentioned acrylic polymer 1 solution (40% by mass) was diluted to 20% by mass with ethyl acetate, and to 500 parts by mass of this solution (100 parts by mass of solid content) was added as a crosslinking agent and as a trifunctional isocyanate compound. 1.5 parts by mass (1.5 parts by mass of solid content) of isocyanurate form of hexamethylene diisocyanate (manufactured by Tosoh Corporation, "Coronate HX"), isophorone diisocyanate as a difunctional isocyanate compound (Mitsui Chemicals Made by the company, "Takenate 600") 0.15 parts by mass (solid content 0.15 parts by mass), dioctyltin dilaurate as a crosslinking catalyst (manufactured by Tokyo Fine Chemical Co., Ltd., "Embilizer OL-1", 1 mass % ethyl acetate solution ) 3 parts by mass (0.03 parts by mass of solid content), 0.5 parts by mass of tris(acetylacetonate)iron (manufactured by Nippon Chemical Industry Co., Ltd., "Nacem Fe(III)", 1 mass % ethyl acet...

Embodiment 2

[0227] A surface protection film was produced by the method similar to Example 1 except having used the acrylic polymer 2 instead of the acrylic polymer 1 used in Example 1.

Embodiment 3

[0229] Using Acrylic Polymer 2 instead of Acrylic Polymer 1 used in Example 1, triethylpentyl ・Bis(trifluoromethanesulfonyl)imide salt) 0.1 part by mass (solid content 0.1 part by mass) instead of tributylmethyl - A surface protection film was produced in the same manner as in Example 1 except that bis(trifluoromethanesulfonyl)imide salt) was 0.1 parts by mass (solid content: 0.1 parts by mass).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com