Method for producing water-soluble ammonium polyphosphate by using extraction wet-process phosphoric acid

A technology of ammonium polyphosphate and wet-process phosphoric acid, applied in ammonium orthophosphate fertilizers, chemical instruments and methods, alkaline orthophosphate fertilizers, etc., can solve problems such as overflow, achieve low production cost, short reaction time, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

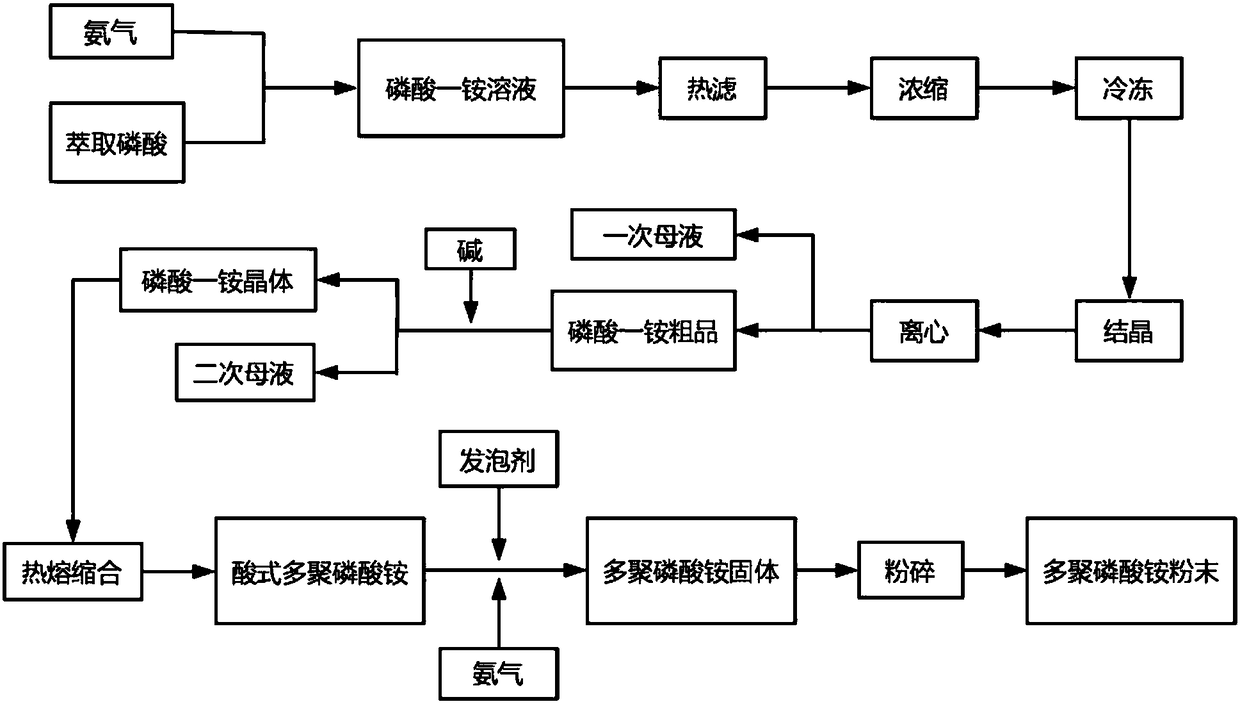

Method used

Image

Examples

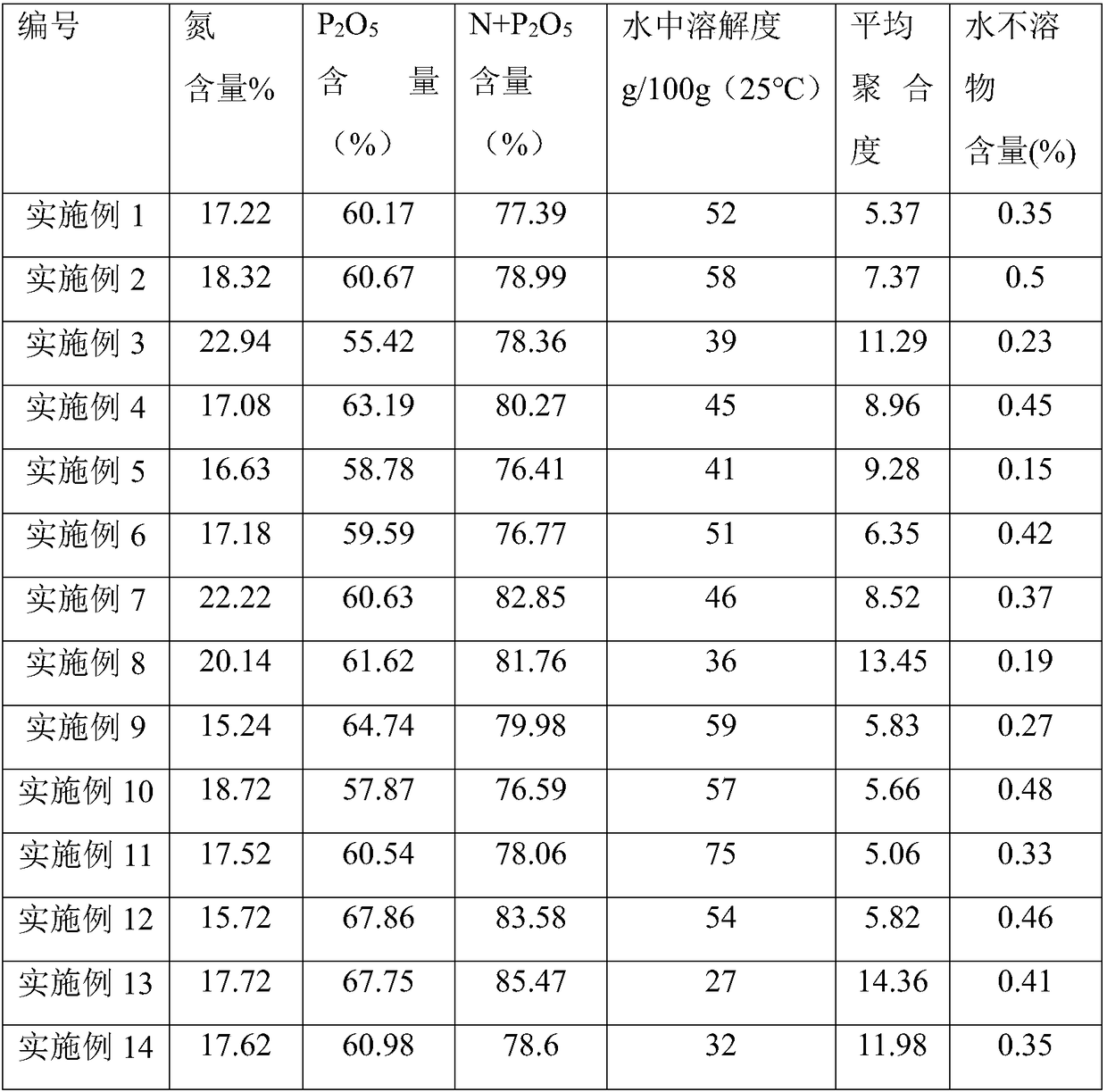

Embodiment 1

[0035] (1) Ammonia gas is continuously fed into a reactor for extracting wet-process phosphoric acid with 2000Kg20% content, reacted at 110°C to generate monoammonium phosphate, and the reaction time is 120 minutes. The reaction solution is concentrated by hot filtration, frozen crystallization, centrifuged Separation to obtain crude monoammonium phosphate and a primary mother liquor; the crude monoammonium phosphate is washed with triethylamine lye to obtain 400kg monoammonium phosphate crystals and a secondary mother liquor; the triethylamine lye in the secondary mother liquor is recovered to obtain a third mother liquor , Triethylamine lye is applied mechanically, the primary mother liquor and the third mother liquor are combined and discharged, and enter the system for producing industrial grade monoammonium phosphate by other methods.

[0036] (2) Turn on the heating device, raise and maintain the temperature of the fixed bed reactor at 350°C, add ammonium hydrogen phospha...

Embodiment 2

[0039] (1) Ammonia gas is continuously fed into a reactor with 1000Kg50% content to extract wet-process phosphoric acid, reacted at 80°C to generate monoammonium phosphate, the reaction time is 60 minutes, concentrated through hot filtration, frozen crystallization, and centrifuged to obtain Monoammonium phosphate crude product and primary mother liquor; The monoammonium phosphate crude product is washed with monoethanolamine lye to obtain 500kg monoammonium phosphate crystals and secondary mother liquor; the lye in the secondary mother liquor is recovered and processed to obtain three mother liquors, and monoethanolamine lye is used mechanically. The primary mother liquor and the tertiary mother liquor are combined and discharged, and enter the system for producing industrial grade monoammonium phosphate by other methods.

[0040] (2) Turn on the heating device, raise and maintain the temperature of the fixed bed reactor at 200°C, continuously add ammonium hydrogen phosphate s...

Embodiment 3

[0043] (1) Ammonia gas is continuously fed into a reactor with 500Kg85% content to extract wet-process phosphoric acid, and reacted at 100°C to generate monoammonium phosphate. The reaction time is 100 minutes, concentrated by hot filtration, frozen and crystallized, and centrifuged to obtain Monoammonium phosphate crude product and primary mother liquor; Monoammonium phosphate crude product is washed with ethylenediamine lye to obtain 415kg monoammonium phosphate crystals and secondary mother liquor; ethylenediamine lye in secondary mother liquor is recovered to obtain three mother liquors, ethylenediamine The amine lye is used mechanically, and the primary mother liquor and the tertiary mother liquor are combined and discharged, and enter the system for producing industrial grade monoammonium phosphate by other methods.

[0044] (2) Turn on the heating device, raise the temperature of the fixed bed reactor to and keep it at 250°C, continuously add ammonium hydrogen phosphate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com