Secondary forming process for preparing material with high elastic resilience by utilizing thermoplastic polyurethane elastomer (E-TPU) particles

A secondary molding and resilience technology, applied in applications, home appliances, other home appliances, etc., can solve the problems of increasing process and cost, limiting design scope, simple color, etc., saving process and cost, extending design scope, The effect of labor cost improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

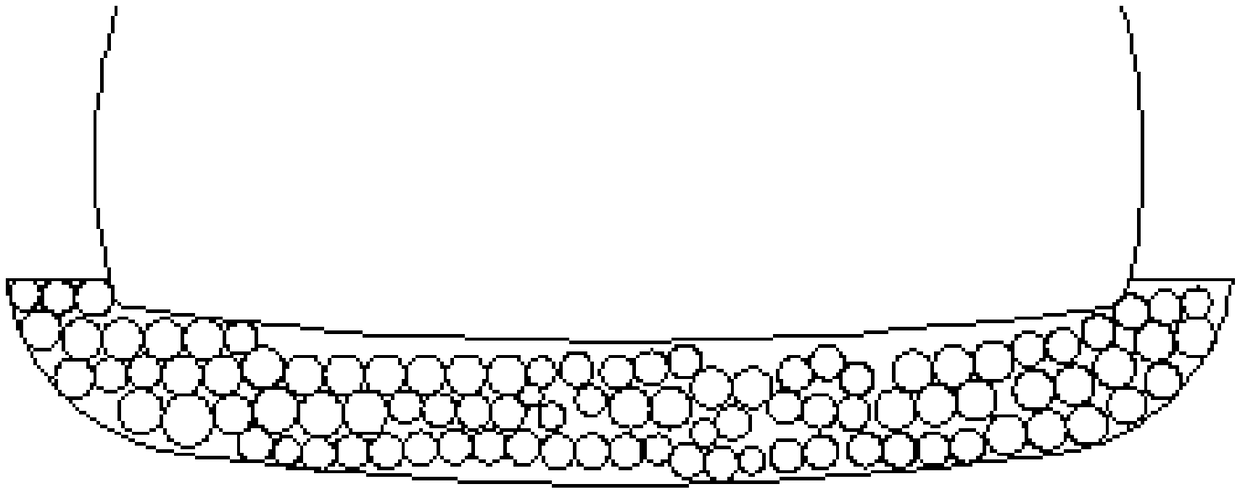

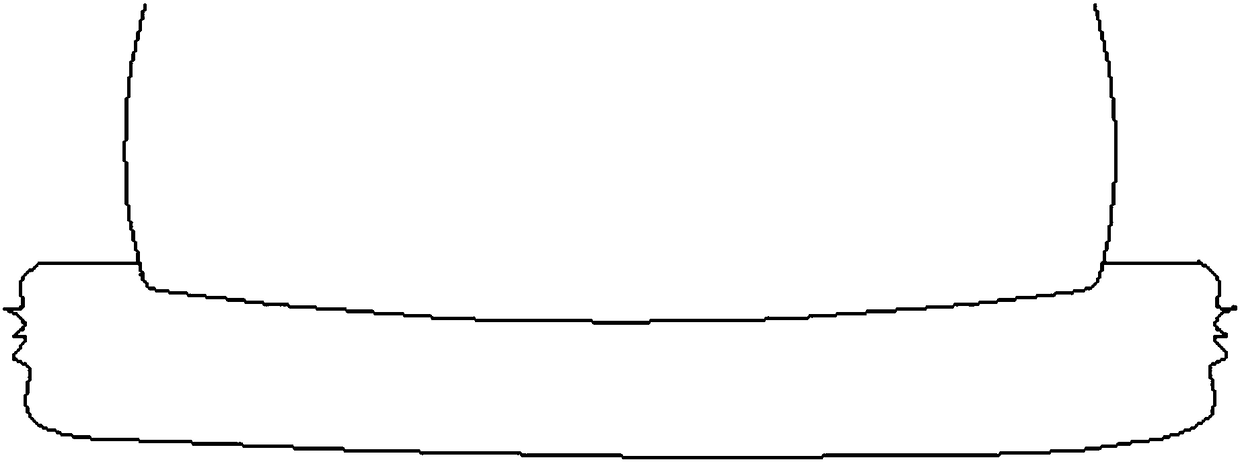

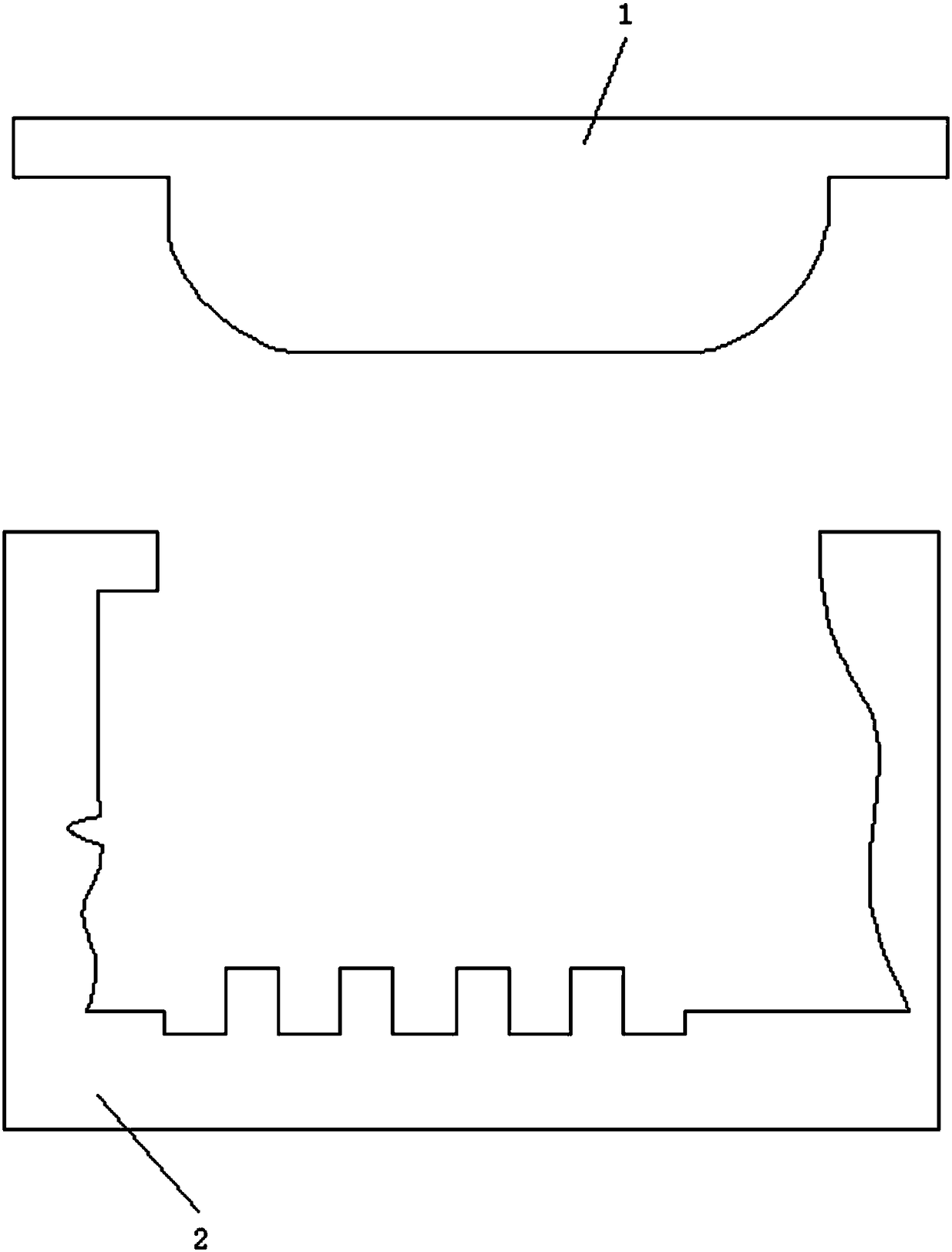

[0038] refer to Figure 3-5 , this embodiment provides a secondary molding process for preparing high resilience materials using E-TPU particles, including the following steps:

[0039] Step 1: Through the steam molding process, use E-TPU particles to make E-TPU rough blank 3. Where detailed patterns need to be made, the design details can be ignored so that the particles can be filled; if necessary, add decorations or details later The place where the pattern is reserved, that is, the position of accessories is reserved on the E-TPU rough blank 3; specifically, the accessories include wear-resistant rubber outsole 4, decorative parts or a combination of the above two.

[0040] Ignoring the original design details means that, for example, the width and depth of the design pattern of some soles are 1mm and 2mm respectively, but the existing E-TPU molding process cannot make such a small pattern, so , what the present invention emphasizes is to ignore such design details at thi...

Embodiment 2

[0047] refer to Figure 3-5 , this embodiment provides a secondary molding process for preparing high resilience materials using E-TPU particles, including the following steps:

[0048] Step 1: Through the steam molding process, use E-TPU particles to make E-TPU rough blank 3. Where detailed patterns need to be made, the design details can be ignored so that the particles can be filled; if necessary, add decorations or details later The reserved position of the pattern, that is, the reserved position of accessories on the E-TPU rough blank 3; specifically, the accessories include wear-resistant rubber outsole 4, decorative parts or a combination of the above two.

[0049] Ignoring the original design details means that, for example, the width and depth of the design pattern of some soles are 1mm and 2mm respectively, but the existing E-TPU molding process cannot make such a small pattern, so , what the present invention emphasizes is to ignore such design details at this stage,...

Embodiment 3

[0056] refer to Figure 3-5 , this embodiment provides a secondary molding process for preparing high resilience materials using E-TPU particles, including the following steps:

[0057] Step 1: Through the steam molding process, use E-TPU particles to make E-TPU rough blank 3. Where detailed patterns need to be made, the design details can be ignored so that the particles can be filled; if necessary, add decorations or details later The reserved position of the pattern, that is, the reserved position of accessories on the E-TPU rough blank 3; specifically, the accessories include wear-resistant rubber outsole 4, decorative parts or a combination of the above two.

[0058] Ignoring the original design details means that, for example, the width and depth of the design pattern of some soles are 1mm and 2mm respectively, but the existing E-TPU molding process cannot make such a small pattern, so , what the present invention emphasizes is to ignore such design details at this stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com