A rapid prototyping method for microwave solidified water-soluble salt core

A microwave curing, water-soluble salt technology, used in cores, mold components, casting molding equipment, etc., can solve the problems of low salt core strength, easy corrosion of nozzles, short service life, etc., to achieve fast curing speed and avoid scratches , to ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

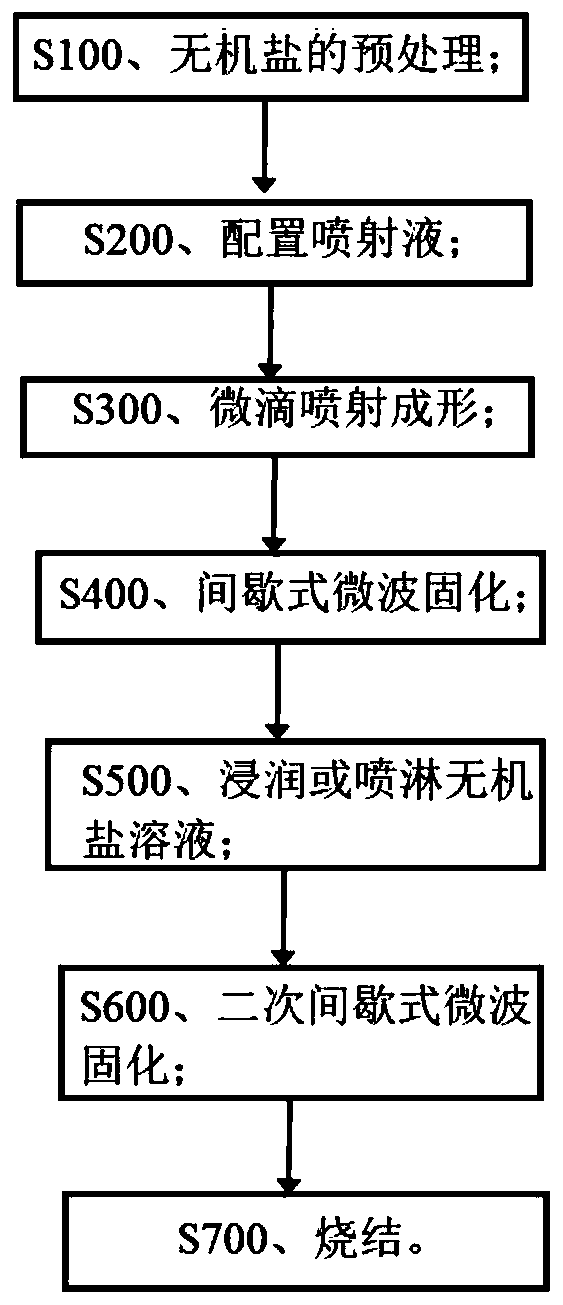

[0043] A kind of rapid prototyping method of microwave curing water-soluble salt core of the present embodiment, comprises the following steps:

[0044] S100, pretreatment of inorganic salts, drying one or more water-soluble inorganic salts, grinding, mixing, and sieving to obtain 100-200 mesh salt powder for later use;

[0045] S200, configure the spray liquid, mix the water and the additive evenly, and configure it into an aqueous solution with a viscosity of 1-10cps;

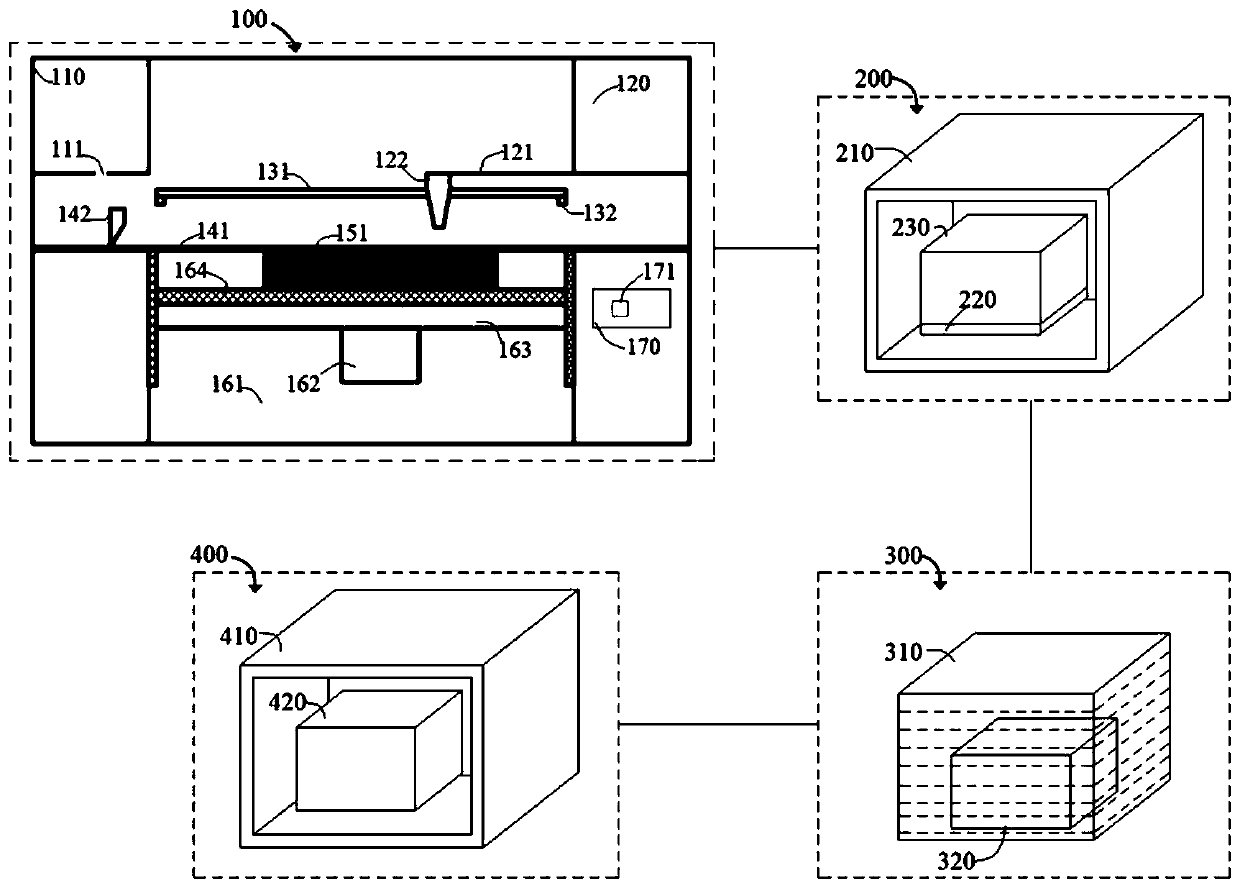

[0046] S300, micro-droplet injection forming, flatly spread the ground and screened inorganic salt powder on the lifting workbench 163, and the micro-droplet injection nozzle sprays the aqueous solution configured in S200 according to the drop path generated by the solid model of the salt core, and wait until the layer is micro After the droplet spraying is completed, the lifting table goes down by 0.01-1mm, and the subsequent dripping process of discrete layers is completed in turn until the dripping process...

Embodiment 2

[0062] A kind of rapid prototyping method of microwave curing water-soluble salt core of the present invention, its forming process is as follows:

[0063] S100, pretreatment of inorganic salt, drying potassium carbonate at 160-180°C, then ball milling and sieving on a ball mill to obtain 140-200 mesh salt powder for later use;

[0064] S200, configure the spray liquid, dissolve polyethylene glycol and starch into water, and configure a solution with a viscosity of 3-5cps;

[0065] S300. Droplet jet forming of water-soluble salt core. Lay the ground and sieved potassium carbonate powder on the lifting workbench 163, and spray the aqueous solution configured by S200 according to the droplet path generated by the solid model of the salt core. The platform 163 goes down by 0.02mm, and completes the subsequent dripping processes on discrete levels in sequence until the dripping processes on all discrete levels are completed;

[0066] S400, intermittent microwave curing. Take ou...

Embodiment 3

[0070] A kind of rapid prototyping method of microwave curing water-soluble salt core of the present invention, its forming process is as follows:

[0071] S100, pretreatment of inorganic salts. Potassium carbonate and potassium chloride are dried at 160-180°C and 100-105°C, respectively, and then ball milled and sieved on a ball mill to obtain two salt powders of 140-200 mesh for use;

[0072] S200, configure the spray liquid, dissolve polyacrylamide, polyethylene glycol, fatty acid sorbitan and polysorbate into water, and configure it into a solution with a viscosity of 3-5cps;

[0073] S300, micro-droplet spray forming of water-soluble salt core, the ground and screened potassium carbonate powder and potassium chloride powder are mixed evenly according to the mass ratio of 6:4, and then spread on the lifting workbench 163, and micro-drop spraying The spray head sprays the aqueous solution configured by S200 according to the droplet path generated by the solid model of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com