Pd-Mg/C catalyst for preparing 2,3-dichloropyridine by catalytic hydrogenation of 2,3,6-trichloropyridine and preparation method of Pd-Mg/C catalyst

A technology of catalytic hydrogenation and trichloropyridine, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., and can solve the problems of limited industrial application, environmental pollution, and yield Low-level problems, to achieve the effect of improving reusable performance, reducing production costs, and enhancing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

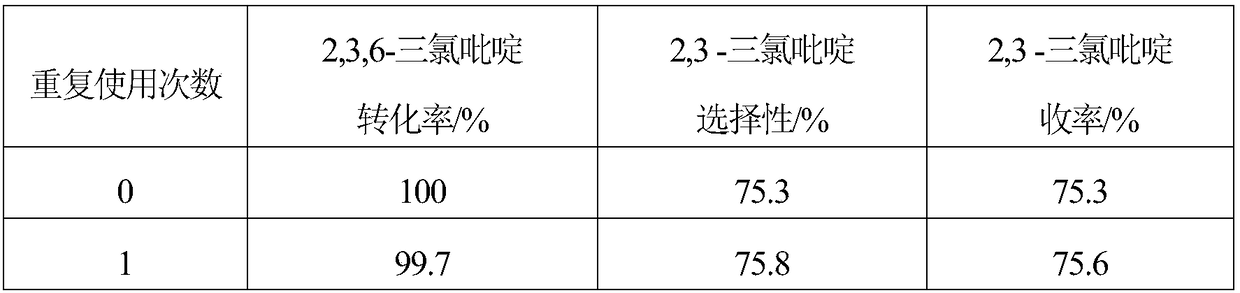

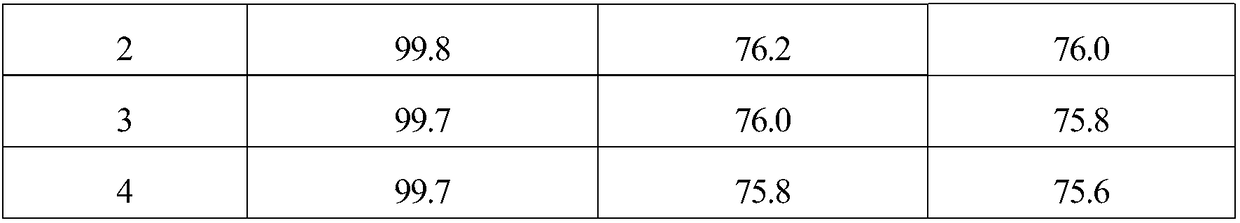

Examples

Embodiment 1

[0018] 1. The specific surface area of 10g is 1562m 2 / g of activated carbon is added to the mixed aqueous solution of 200mL hydrogen peroxide and hydrochloric acid, and the H in the mixed solution 2 o 2 The mass concentration is 10%, the HCl mass concentration is 5%, soaking at room temperature for 1 hour, then boiling for 20 minutes, washing with distilled water until neutral, and obtaining modified activated carbon.

[0019] 2. Mix 6.49g (2.82×10 -2 mol)Na 2 C 4 h 4 o 6 2H 2 Dissolve O in 200mL of distilled water, then add 9.5g of modified activated carbon, stir evenly, raise the temperature to 60°C, stir at constant temperature for 40 minutes, then add 20mL containing 1.38g Na 2 PdCl 4 (4.69×10 -3 mol) and 0.29g MgCl 2 ·6H 2 The aqueous solution of O was continuously stirred at 60°C for 2.5 hours, after standing for layers, the supernatant was poured off, and dried at 120°C.

[0020] 3. The dried sample was reduced in a hydrogen atmosphere at 200°C for 2 hour...

Embodiment 2

[0022] 1. The specific surface area of 10g is 1218m 2 / g of activated carbon is added to the mixed aqueous solution of 200mL hydrogen peroxide and hydrochloric acid, and the H in the mixed solution 2 o 2 The mass concentration is 5%, the HCl mass concentration is 5%, soaking at room temperature for 1 hour, then boiling for 20 minutes, washing with distilled water until neutral, and obtaining modified activated carbon.

[0023] 2. Mix 4.32g (1.88×10 -2 mol)Na 2 C 4 h 4 o 6 2H 2 Dissolve O in 200mL of distilled water, then add 9.5g of modified activated carbon, stir evenly, raise the temperature to 80°C, stir at constant temperature for 60 minutes, then add 20mL containing 1.38g Na 2 PdCl 4 (4.69×10 -3 mol) and 0.17g MgCl 2 ·6H 2 The aqueous solution of O was continuously stirred at 80°C for 3 hours, the supernatant liquid was decanted after standing for stratification, and dried at 120°C.

[0024] 3. The dried sample was reduced in a hydrogen atmosphere at 300°C f...

Embodiment 3

[0026] 1. The specific surface area of 10g is 1989m 2 / g of activated carbon is added to the mixed aqueous solution of 200mL hydrogen peroxide and hydrochloric acid, and the H in the mixed solution 2 o 2 The mass concentration is 15%, the HCl mass concentration is 5%, soaking at room temperature for 1 hour, then boiling for 20 minutes, washing with distilled water until neutral, and obtaining modified activated carbon.

[0027] 2. Mix 8.64g (3.75×10 -2 mol)Na 2 C 4 h 4 o 6 2H 2 Dissolve O in 200mL of distilled water, then add 9.5g of modified activated carbon, stir evenly, raise the temperature to 50°C, stir at constant temperature for 30 minutes, then add 20mL containing 1.38g Na 2 PdCl 4 (4.69×10 -3 mol) and 0.42g MgCl 2 ·6H 2 The aqueous solution of O was continuously stirred at 50°C for 2 hours, the supernatant liquid was decanted after standing for stratification, and dried at 120°C.

[0028] 3. The dried sample was reduced in a hydrogen atmosphere at 250°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com