Preparation method of compound porous molecular sieve catalyst

A catalyst and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of no environmental protection benefit, high cost, large amount of waste liquid, etc., achieve good environmental protection benefits and reduce waste liquid. The effect of generating and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 1 gram of aluminum acetate, 100 grams of silica gel, 14 grams of polyethylene glycol, 3.4 grams of potassium hydroxide and 220 grams of water and stir evenly; stir the mixed solution at 60°C for 20 hours, then seal and age for 50 hours to obtain the precursor A: Precursor A is subjected to solution-free crystallization treatment, including two steps of heating treatment and crystallization treatment. First, the heating treatment temperature is 100 ° C for 12 hours; the crystallization treatment temperature is 170 ° C and the time is 15 hours. The pressure is 1.5 MPa to obtain the precursor B; finally the precursor B is calcined at 600° C. for 8 hours in the air atmosphere to obtain the composite pore molecular sieve catalyst of the present invention.

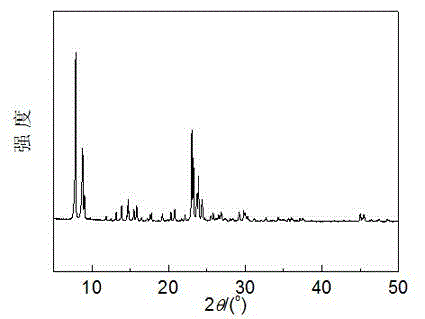

[0025] The XRD spectrum data of the product are shown in Table 1, and the XRD spectrum is as follows figure 1 shown. The particle size of the product is 1.2 microns, and the pore volume of the macropores of 0.5-10 mi...

Embodiment 2~10

[0029] According to the synthesis steps described in [Example 1], the types and amounts of M sources, silicon sources, surfactants, and mineralizers (sodium hydroxide is abbreviated as NaOH, and ethyl ammonium hydroxide is abbreviated as TEAOH) are changed, and the preparation conditions are adjusted. , can be synthesized to obtain the composite pore molecular sieve catalyst of the present invention. Catalyst formulations, preparation conditions and structural composition features are shown in Table 2 and Table 3. The catalyst evaluation method is the same as [Example 1], and the catalytic reaction evaluation results are shown in Table 4.

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com