Preparation method of textured high-curie-point Pr2Ti2O7 ceramic

A high Curie point, textured technology, applied in the field of preparation of Pr2Ti2O7 piezoelectric ceramic materials, can solve the problems of non-dense material structure, complex operation process, long heat treatment cycle, etc., achieve complete appearance rules, broad application prospects, obvious The effect of preferential orientation of the a-axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

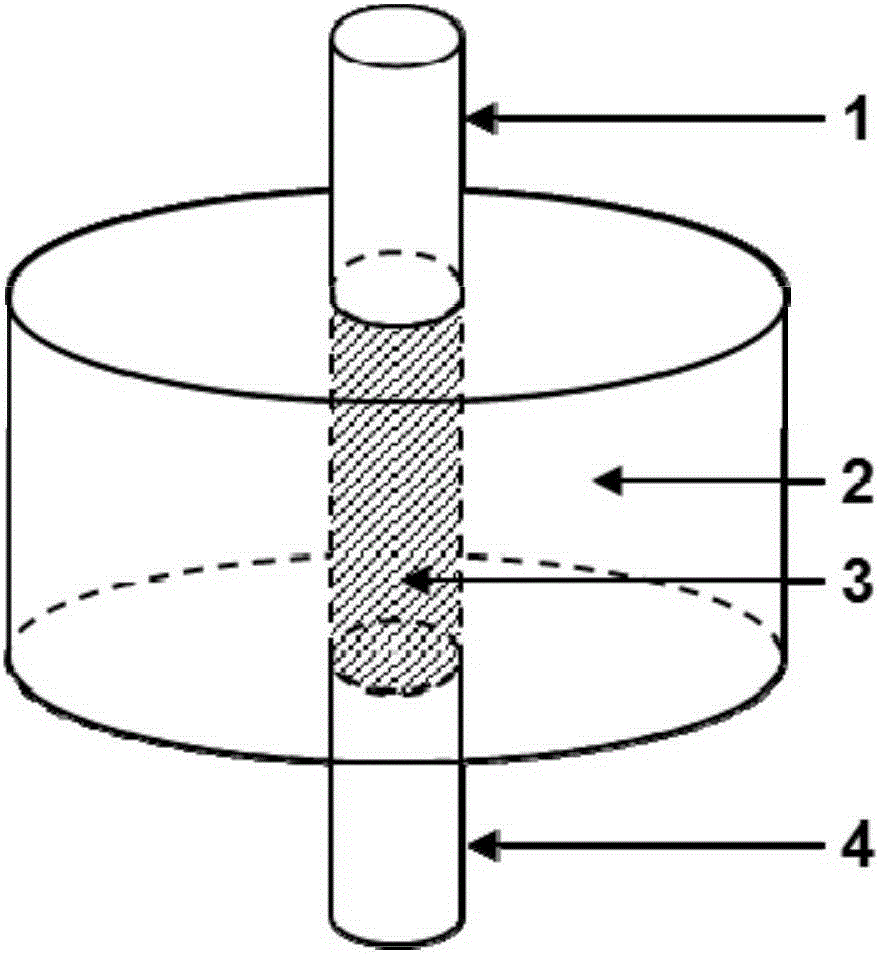

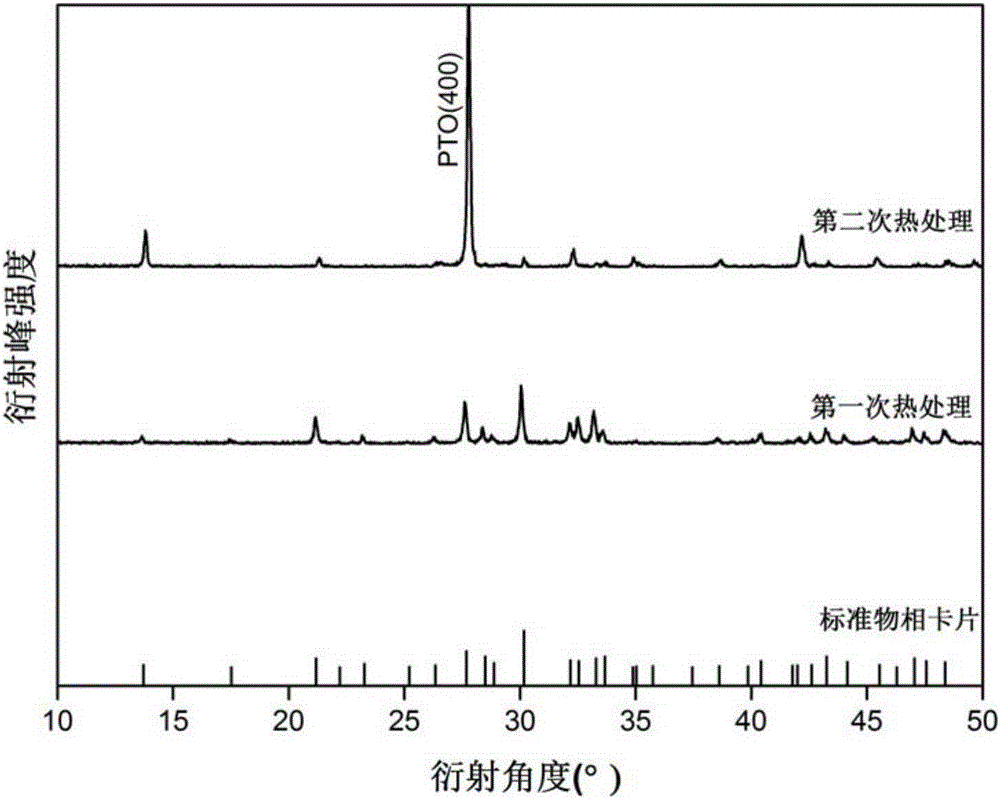

[0027] First, Pr with a purity of 98.5% and a particle size of 1-20 μm 2 Ti 2 o 7 The raw material powder is filled in a high-temperature graphite mold with a diameter of 15mm, and then the mold is moved into a plasma activation sintering furnace for the first plasma activation heat treatment (that is, densification sintering): first activate for 30s, and then heat up at 100°C / min Raise the temperature to 1200°C, keep it warm for 3 minutes and apply an axial pressure of 30MPa. After reaching the holding time, start to lower the temperature, remove the pressure and cool down with the furnace to obtain a Pr with a diameter of 15mm. 2 Ti 2 o 7 ceramic block.

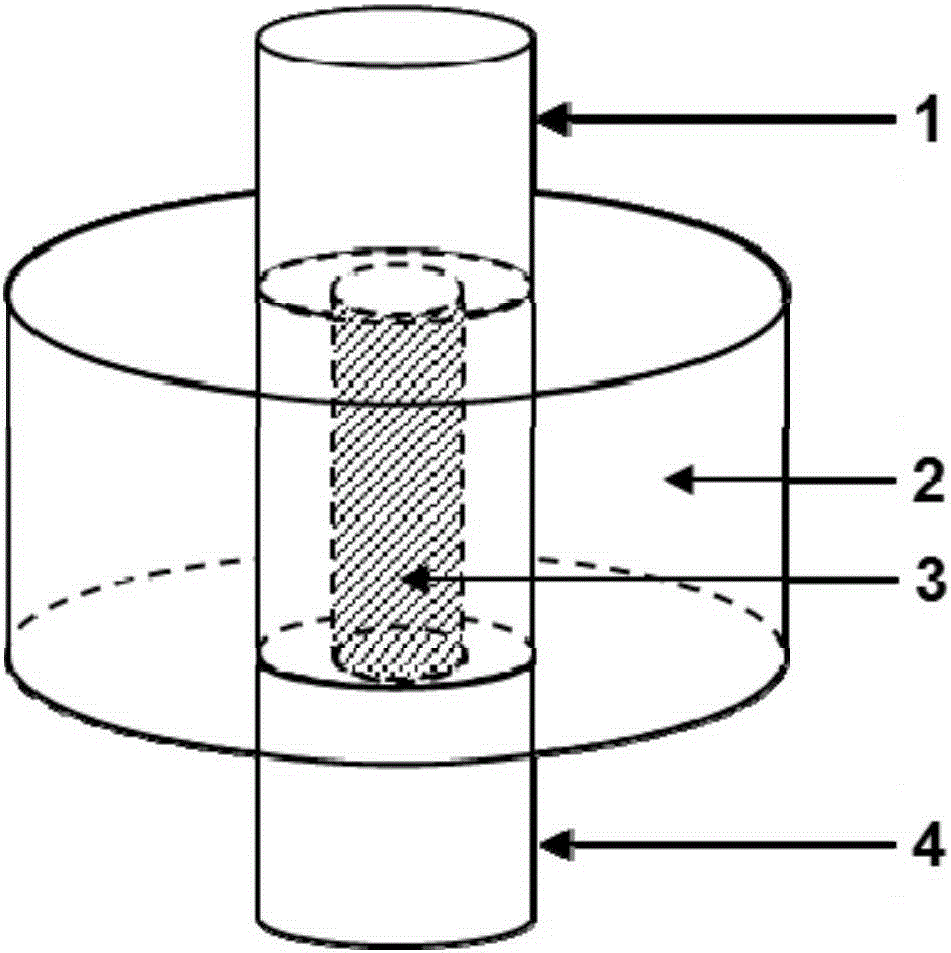

[0028] Second, the Pr 2 Ti 2 o 7 The ceramic block is placed in the center of a high-temperature graphite mold with a diameter of 25mm, and then the mold is moved into a plasma activation sintering furnace for the second plasma activation heat treatment (i.e. texturing molding): first activate for 30s, and then at 5...

Embodiment 2

[0031] First, Pr with a purity of 98.5% and a particle size of 2 Ti 2 o 7 The raw material powder is filled in a high-temperature graphite mold with a diameter of 15mm, and then the mold is moved into a plasma activation sintering furnace for the first plasma activation heat treatment (that is, densification sintering): first activate for 10s, and then heat up at 50°C / min Raise the temperature to 1250°C, keep it warm for 1min and apply an axial pressure of 20MPa. After reaching the holding time, start to lower the temperature, remove the pressure and cool down with the furnace to obtain a Pr with a diameter of 15mm. 2 Ti 2 o 7 ceramic block.

[0032] Second, the Pr 2 Ti 2 o 7 The ceramic block is placed in the center of a high-temperature graphite mold with a diameter of 25mm, and then the mold is moved into a plasma activation sintering furnace for the second plasma activation heat treatment (i.e. texture forming): first activate for 10s, and then at 50°C / min The hea...

Embodiment 3

[0034] First, Pr with a purity of 98.5% and a particle size of 2 Ti 2 o 7 The raw material powder is filled in a high-temperature graphite mold with a diameter of 15mm, and then the mold is moved into a plasma activation sintering furnace for the first plasma activation heat treatment (that is, densification sintering): first activate for 30s, and then heat up at 100°C / min Raise the temperature to 1100°C, keep it warm for 3 minutes and apply an axial pressure of 50MPa. After reaching the holding time, start to lower the temperature, remove the pressure and cool down with the furnace to obtain a Pr with a diameter of 15mm. 2 Ti 2 o 7 ceramic block.

[0035] Second, the Pr 2 Ti 2 o 7 The ceramic block is placed in the center of a high-temperature graphite mold with a diameter of 25mm, and then the mold is moved into a plasma activation sintering furnace for the second plasma activation heat treatment (i.e. texturing molding): first activate for 30s, then at 100°C / min Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com