Hydrolysable protective coating composition, hydrolysable protective coating and composite protective coating layer

A technology for protective coatings and protective coatings, applied in the field of coatings, can solve the problems of environmental and worker hazards, corrosion of the anodic film of aluminum alloy substrates, unsuitable for automation, etc., to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

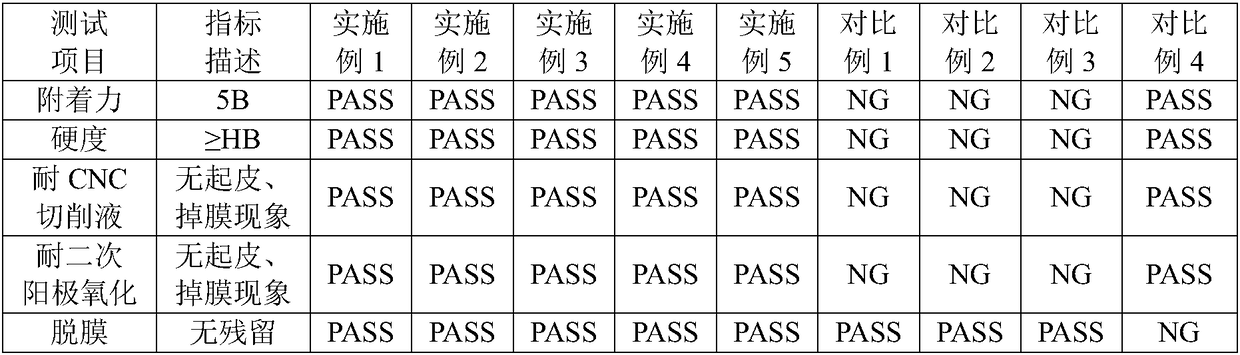

Examples

Embodiment 1

[0052] 1) Preparation of hydrolyzable first coat coating

[0053] Polyvinyl alcohol-124 (purchased from Xilong Chemical Co., Ltd., the degree of polymerization is 2400, and the alcoholysis degree is 99%) 30 grams is dissolved in 500ml pure water; Sodium hydroxymethyl cellulose (purchased from Renqiu Yibang Chemical Co., Ltd.) 15 grams were dissolved in 500 ml of purified water; 2 grams of sodium silicate and 3 grams of glycerin and 1.25 grams of phosphoric acid were dissolved in 100 ml of purified water. After mixing all the above solutions, add 1.5 grams of wetting agent (purchased from Jiangsu Haian Petrochemical Factory, model is MA24P, composition is lauryl phosphate) and defoamer (purchased from Guangzhou Yuheng Chemical Materials Co., Ltd. , the model is Y-687, the composition is glycerol polyether) 1 gram is fully mixed to obtain the first coating, and finally add 1500ml of deionized water to adjust the viscosity of the first coating at 25°C to 10s.

[0054] 2) Form th...

Embodiment 2

[0065] 1) Preparation of hydrolyzable first coat coating

[0066] Polyvinyl alcohol-124 (purchased from Xilong Chemical Co., Ltd., the degree of polymerization is 2400, and the alcoholysis degree is 99%) 40 grams is dissolved in 500ml pure water; Sodium hydroxymethyl cellulose (purchased from Renqiu Yibang Chemical Industry Co., Ltd.) 25 grams were dissolved in 500ml of purified water; 4 grams of sodium silicate, 7 grams of glycerin and 3 grams of phosphoric acid were dissolved in 500 ml of purified water. After mixing all the above solutions, add 2.5 grams of wetting agent (purchased from Hai'an Petrochemical Plant, Jiangsu Province, model is MA24P, composition is lauryl phosphate) and defoamer (purchased from Guangzhou Yuheng Chemical Materials Co., Ltd. , the model is Y-687, the composition is glycerol polyether) 1.5 grams are fully mixed to obtain the first coating, and finally add 1100ml of deionized water to adjust the viscosity of the first coating at 25°C to 12s.

[0...

Embodiment 3

[0078] 1) Preparation of hydrolyzable first coat coating

[0079] Polyvinyl alcohol-124 (purchased from Xilong Chemical Co., Ltd., the degree of polymerization is 2400, and the alcoholysis degree is 99%) 35 grams is dissolved in 500ml pure water; Sodium hydroxymethyl cellulose (purchased from Renqiu Yibang Chemical Industry Co., Ltd.) 20 grams were dissolved in 500ml of purified water; 3 grams of sodium silicate, 4 grams of glycerin and 2.5 grams of phosphoric acid were dissolved in 500 ml of purified water. After mixing all the above solutions, add 2 grams of wetting agent (purchased from Jiangsu Haian Petrochemical Factory, model is MA24P, composition is lauryl phosphate) and defoamer (purchased from Guangzhou Yuheng Chemical Materials Co., Ltd. , the model is Y-687, the composition is glycerol polyether) 1.3 grams are fully mixed to obtain the first coating, and finally add 1200ml of deionized water to adjust the viscosity of the first coating at 25°C to 11s.

[0080] 2) F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com