System and method for carrying out electrolysis treatment on high-chlorine desulfurization wastewater and coupling denitration and mercury removal

A technology for desulfurization wastewater and electrolysis treatment, applied in separation methods, gas treatment, return water treatment, etc., can solve the problems of reduced activity, high use cost, increased disposal difficulty, etc., to increase NO2 content, improve SCR efficiency, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

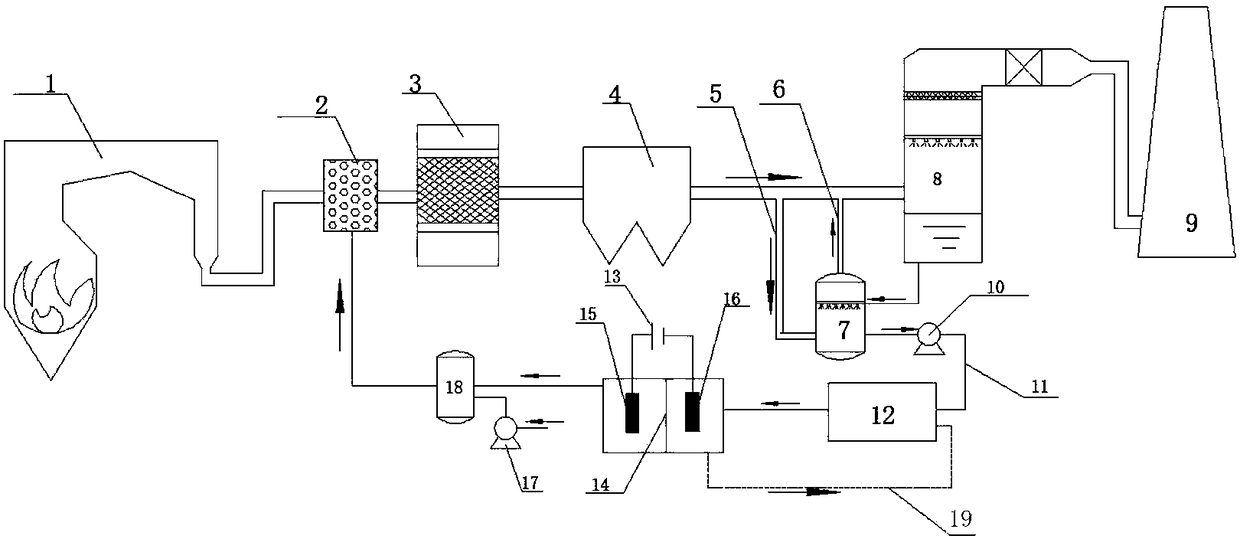

[0050] The present invention provides a treatment method and system for electrolytic treatment of high-chloride desulfurization wastewater and for coupling synchronous denitrification and mercury removal. The present invention will be further described below in conjunction with the accompanying drawings and examples, but the contents of the examples are not regarded as the scope of protection of the present invention. limit.

[0051] Such as figure 1 As shown, an electrolytic treatment of high-chloride desulfurization wastewater coupled with denitrification and mercury removal system, including the pre-SCO system, SCR system, dust collector, wet flue gas desulfurization system and desulfurization wastewater flue gas connected in sequence through the flue Concentration tower; the bottom of the desulfurization waste water flue gas concentration tower is connected to the flue and has a waste water pipeline, and the top is connected to the waste water pipe of the wet flue gas desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com