Gas barrier adhesive, film and gas barrier film

A technology of adhesives and gas barrier properties, which is applied in the fields of thin films, gas barrier films, and gas barrier adhesives. It can solve the problems of damage to the appearance of films, poor ink resolvability, and difficulty in coating, etc., and achieve excellent The effect of appearance and excellent adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083]

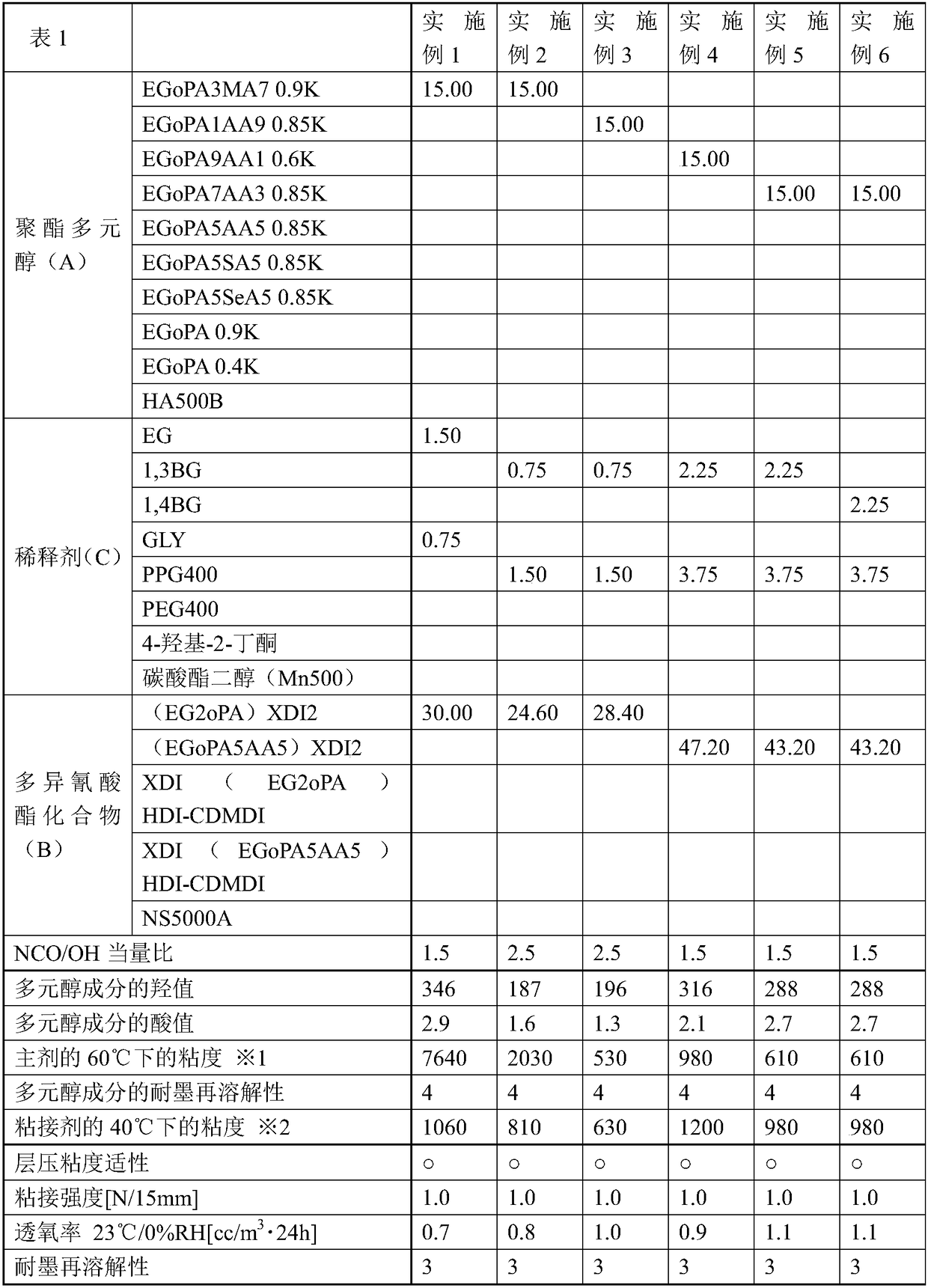

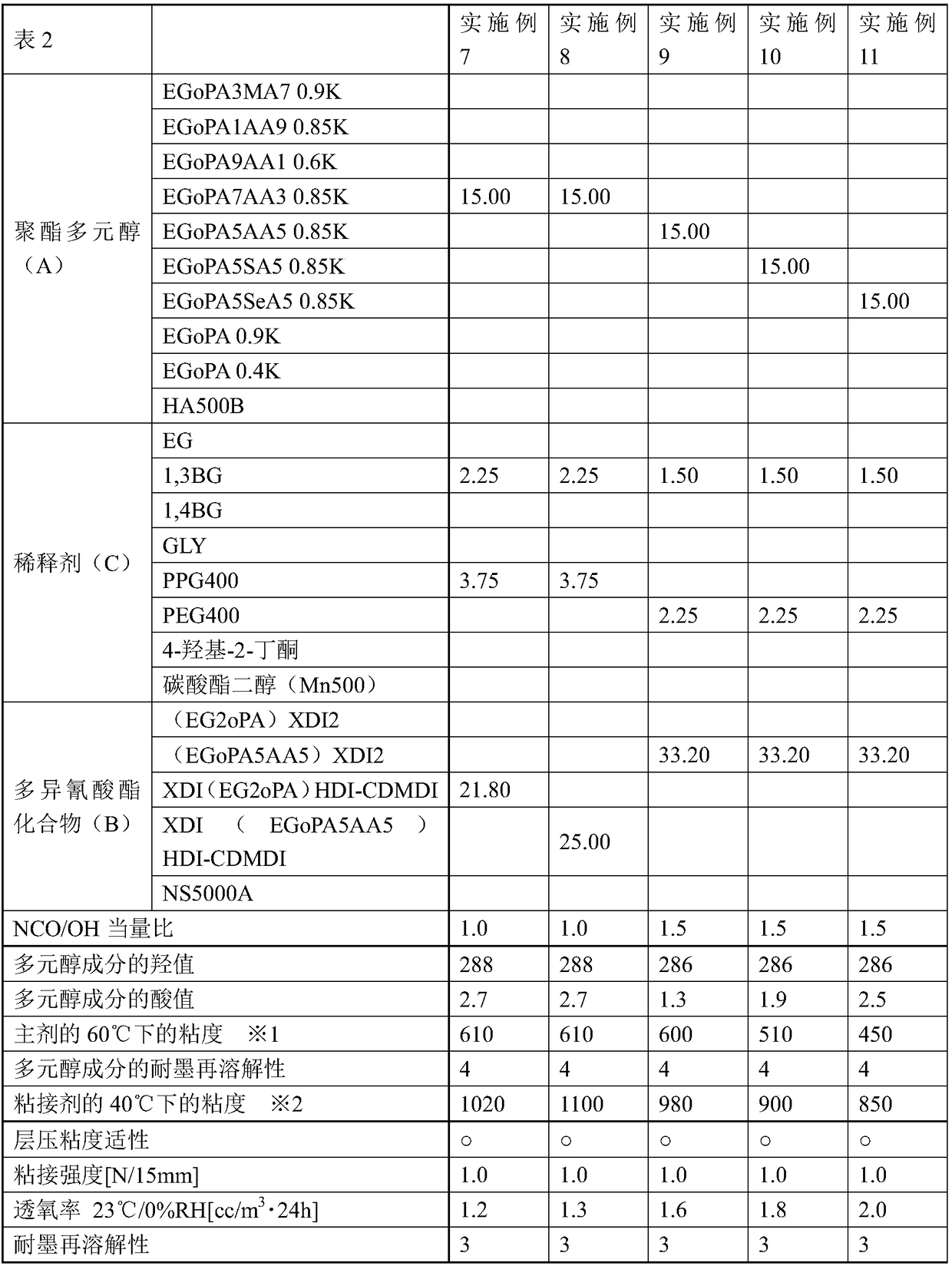

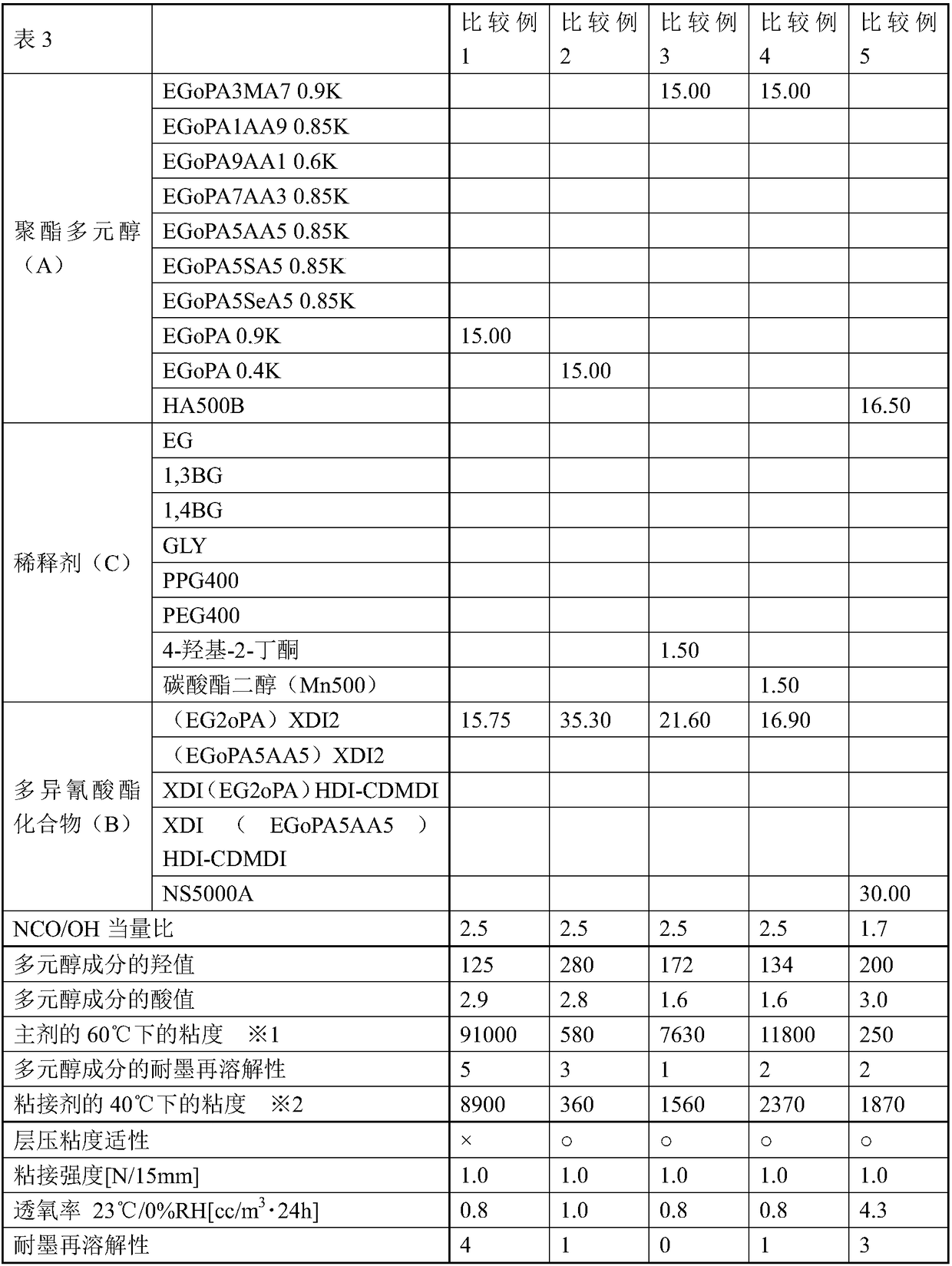

[0084] Next, the present invention will be specifically described by way of examples and comparative examples. In the examples, unless otherwise specified, "parts" and "%" are based on mass.

manufacture example 1

[0085] (Manufacturing example 1) Polyester polyol (A) "EGoPA3MA70.9K" made of ethylene glycol, phthalic anhydride, and maleic acid

[0086] 851.3 parts of ethylene glycol, 474.15 parts of phthalic anhydride, 732.3 parts of maleic anhydride, and tetraisopropanol were put into a polyester reaction vessel equipped with a stirrer, a nitrogen introduction tube, a Snyder tube, and a condenser. 0.10 part of titanium was slowly heated so that the temperature of the upper portion of the rectifying tube did not exceed 100°C, and the internal temperature was kept at 200°C. When the acid value becomes below 5.0mgKOH / g, the esterification reaction is completed, and the design functional group number N=2, the hydroxyl value=125, the theoretical number average molecular weight calculated according to the hydroxyl value is 900, and the viscosity at 60°C is 25000mPa· s polyester polyol (A) "EGoPA3MA7 0.9K".

manufacture example 2

[0087] (Manufacturing example 2) Polyester polyol (A) "EGoPA1AA90.85K" made of ethylene glycol, phthalic anhydride, and adipic acid

[0088] In a polyester reaction vessel equipped with a stirrer, a nitrogen gas introduction pipe, a Snyder tube, and a condenser, 703.62 parts of ethylene glycol, 131.22 parts of phthalic anhydride, 1165.19 parts of adipic acid and 0.10 part of titanium tetraisopropoxide were added, Heating was performed gradually so that the temperature of the upper portion of the rectifying tube did not exceed 100°C, and the inner temperature was kept at 200°C. When the acid value becomes below 5.0mgKOH / g, the esterification reaction is completed, and the number of designed functional groups N=2, the hydroxyl value=135, the theoretical number average molecular weight calculated according to the hydroxyl value is 850, and the viscosity at 60°C is 850mPa. s polyester polyol (A) "EGoPA1AA9 0.85K".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com