Iron oxide/titanium carbide composite cathode material and preparation method thereof

A negative electrode material, titanium carbide technology, used in battery electrodes, electrical components, circuits, etc., can solve the problems of easy agglomeration of nanoparticles, low cycle life, low electrical conductivity, etc., and achieve low agglomeration rate, low cost, and excellent electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

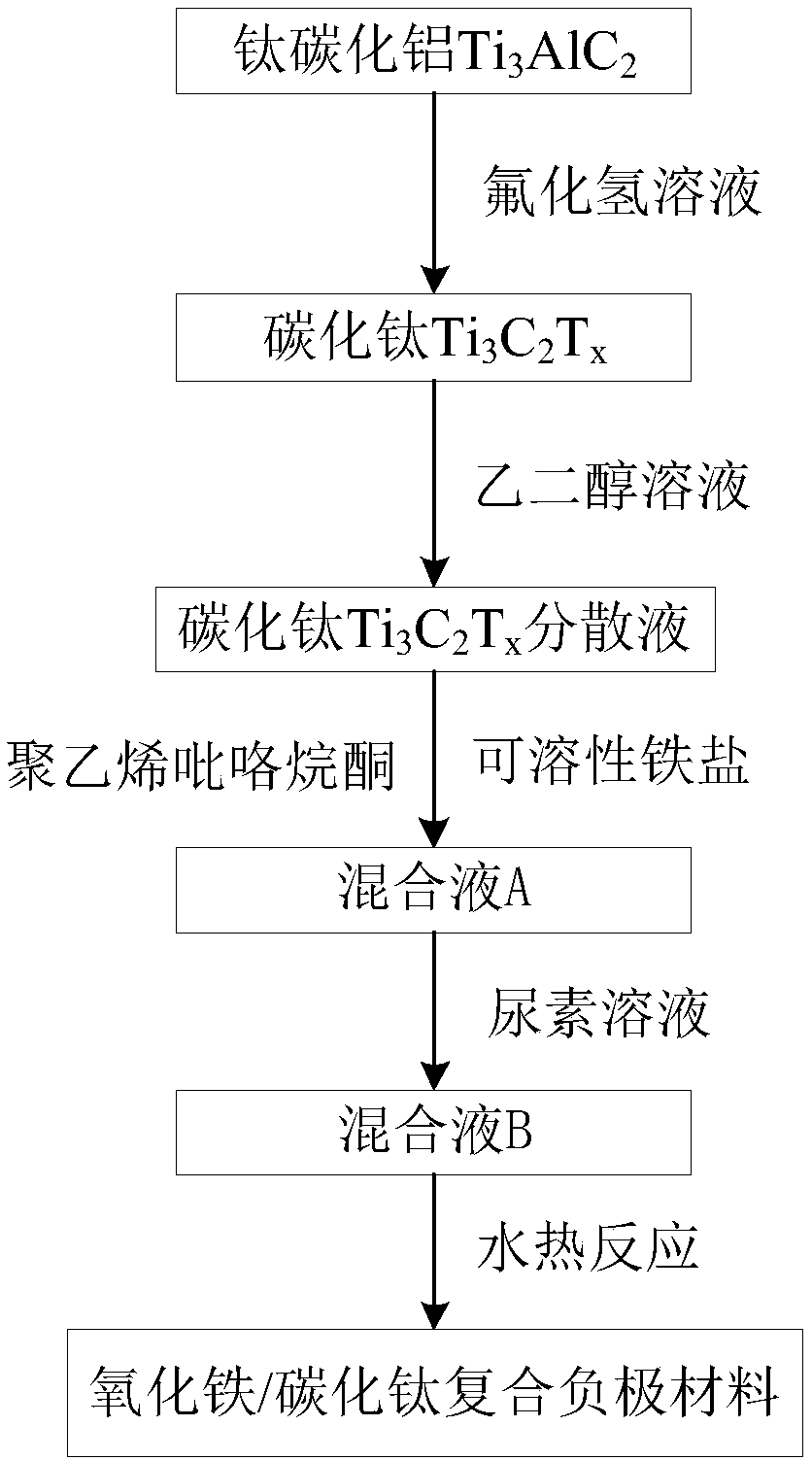

[0033] This embodiment provides a preparation method of iron oxide / titanium carbide composite negative electrode material, such as figure 1 As shown, the method includes the following steps:

[0034] 1) Weigh commercially available titanium aluminum carbide Ti 3 AlC 2 10g was added to 600ml of HF solution with a concentration of 40%, stirred at room temperature for 20h, then centrifuged and washed with water to obtain two-dimensional titanium carbide Ti 3 C 2 T x Materials, where T refers to surface groups, such as F, O, OH, etc.

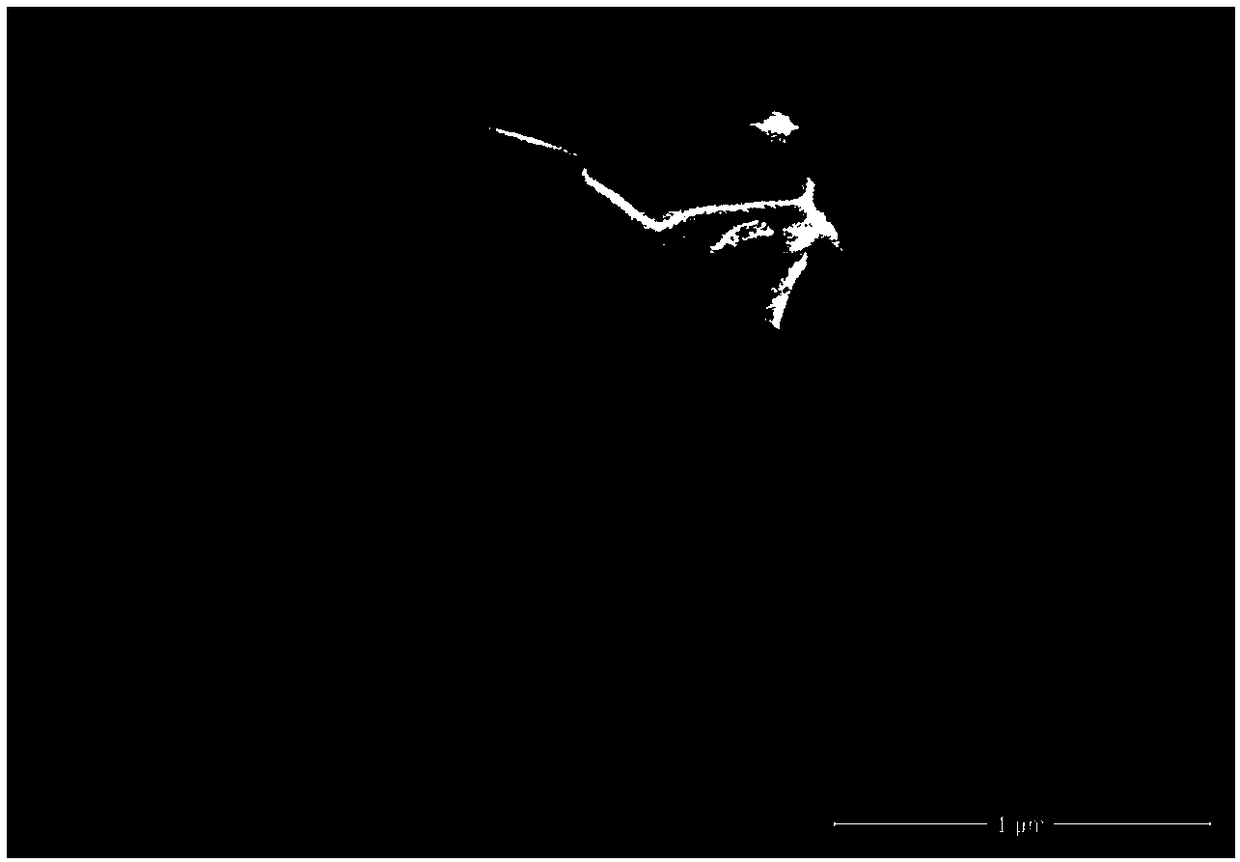

[0035] Such as figure 2 Shown is the two-dimensional titanium carbide Ti prepared above 3 C 2 T x The scanning electron microscope photo of the material, as can be seen from the figure, the prepared two-dimensional titanium carbide Ti 3 C 2 T x The material is a multi-layer sheet structure.

[0036] 2) Weigh the two-dimensional titanium carbide Ti prepared in step 1) 3 C 2 T x Add 1g of material to 500ml of ethylene glycol solution ...

Embodiment 2

[0045] This embodiment provides a preparation method of iron oxide / titanium carbide composite negative electrode material, such as figure 1 As shown, the method includes the following steps:

[0046] 1) Weigh commercially available titanium aluminum carbide Ti 3 AlC 2 10g was added to 500ml of HF solution with a concentration of 10%, stirred at room temperature for 24h, then centrifuged and washed with water to obtain two-dimensional titanium carbide Ti 3 C 2 T x Materials, where T refers to surface groups, such as F, O, OH, etc.

[0047] By scanning electron microscopy, the two-dimensional titanium carbide Ti 3 C 2 T x The material structure is consistent with that in Example 1, which is a multilayer sheet structure.

[0048] 2) Weigh the two-dimensional titanium carbide Ti prepared in step 1) 3 C 2 T x Add 1g of material to 500ml of ethylene glycol solution with a volume concentration of 10%, and stir for 1h to obtain uniform titanium carbide Ti 3 C 2 T x Disp...

Embodiment 3

[0054] This embodiment provides a preparation method of iron oxide / titanium carbide composite negative electrode material, such as figure 1 As shown, the method includes the following steps:

[0055] 1) Weigh commercially available titanium aluminum carbide Ti 3 AlC 2 10g was added to 800ml of HF solution with a concentration of 30%, stirred at room temperature for 8h, then centrifuged and washed with water to obtain two-dimensional titanium carbide Ti 3 C 2 T x Materials, where T refers to surface groups, such as F, O, OH, etc.

[0056] 2) Weigh the two-dimensional titanium carbide Ti prepared in step 1) 3 C 2 T x Add 1g of material to 500ml of ethylene glycol solution with a volume concentration of 50%, stir for 1h to obtain uniform titanium carbide Ti 3 C 2 T x Dispersion liquid, wherein, Ti 3 C 2 T x Ti in the dispersion 3 C 2 T x The mass volume concentration is 2mg / ml.

[0057] 3) Weigh 2.7g FeCl 3 ·6H 2 O(Fe 3+ 0.01mol) and 0.5g polyvinylpyrrolidone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com