Lithium metal anode material protected by natural macromolecular polymer as well as preparation method and application of lithium metal anode material

A natural polymer and lithium metal negative electrode technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of difficult large-scale application, in-situ growth, and harsh reaction conditions, and achieve easy scale The effect of production, inhibition of lithium branch crystal growth, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Agarose is added into water, stirred in a 95°C water bath until it is completely dissolved, and the obtained concentration is a 5wt% agarose solution; the structural formula of the above-mentioned agarose is

[0042](2) Apply the above-mentioned agarose solution evenly on the pure copper foil, and then vacuum-dry it at 80°C for 10h to obtain a copper current collector with a protective layer (0.5-3 μm in thickness). The tensile strength and The results of 180°peeling are as follows figure 1 and figure 2 shown;

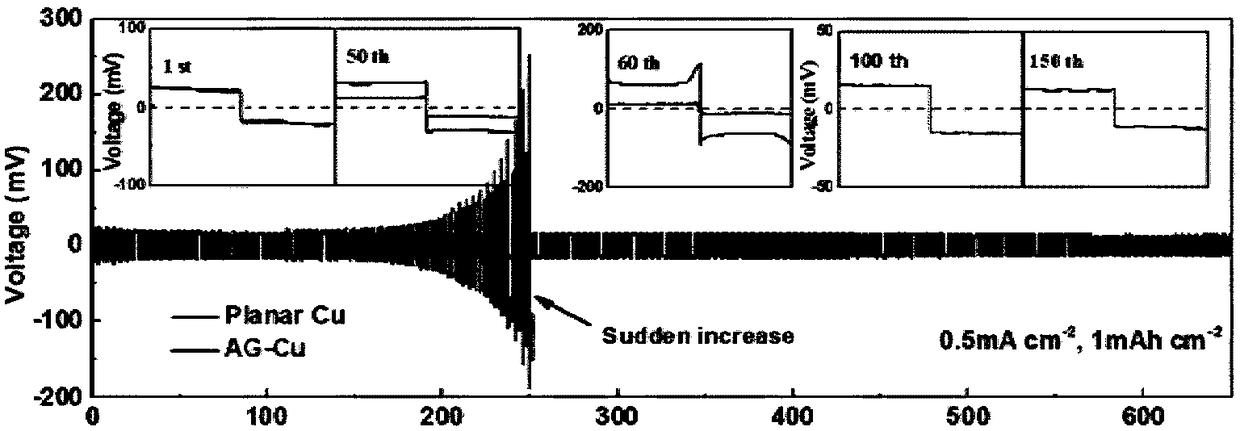

[0043] (3) Combine the above-mentioned copper current collector, Celgard 2400 diaphragm and metal lithium sheet into a half-cell, place it in the electrolyte, and 2 Uniform deposition of 4mAh / cm at a current density of 2 Lithium metal, that is, AG-Cu@Li lithium metal negative electrode, 0.5M bistrifluoromethanesulfonate lithium and 0.5M lithium nitrate in the electrolyte as the conductive salt, the solvent is DME and DOL with a volume ratio of 1:1 com...

Embodiment 2

[0053] (1) Tamarind seed glue (TSP) is added in water, and magnetic stirring is until all dissolvings, and obtaining concentration is the tamarind seed glue solution of 2wt%; The structural formula of above-mentioned tamarind seed glue is as follows Figure 11 as shown,

[0054] (2) Evenly scrape-coat the above-mentioned tamarind seed glue solution on the pure copper foil, and then vacuum-dry it at 80° C. for 10 hours to obtain a copper current collector with a protective layer (0.5-3 μm in thickness);

[0055] (3) Combine the above-mentioned copper current collector, Celgard 2400 diaphragm and metal lithium sheet into a half-cell, place it in the electrolyte, and 2 Uniform deposition of 4mAh / cm at a current density of 2 Metal lithium, that is, TSP-Cu@Li lithium metal negative electrode, 0.5M bistrifluoromethanesulfonate lithium and 0.5M lithium nitrate in the electrolyte as conductive salt, solvent DME and DOL with a volume ratio of 1:1 composed of mixed solvents.

[0056]...

Embodiment 3

[0058] (1) Sodium alginate (SA) is added in water, magnetically stirred until all dissolve, and obtaining concentration is the sodium alginate solution of 2wt%; The structural formula of above-mentioned sodium alginate is

[0059] (2) Evenly scrape-coat the above-mentioned sodium alginate solution on the pure copper foil, and then vacuum-dry it at 80°C for 10 hours to obtain a copper current collector with a protective layer (0.5-3 μm in thickness);

[0060] (3) The above-mentioned copper current collector, Celgard2400 separator and metal lithium sheet are combined into a half-cell, placed in the electrolyte, at 0.5mA / cm 2 Uniform deposition of 4mAh / cm at a current density of 2 Metal lithium, that is, SA-Cu@Li lithium metal negative electrode, 0.5M bistrifluoromethanesulfonate lithium and 0.5M lithium nitrate in the electrolyte as conductive salt, solvent DME and DOL with a volume ratio of 1:1 composed of mixed solvents.

[0061] In this embodiment, the cycle stability met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com