Method for rapidly and efficiently recycling neodymium iron boron waste

A NdFeB, Scrap Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

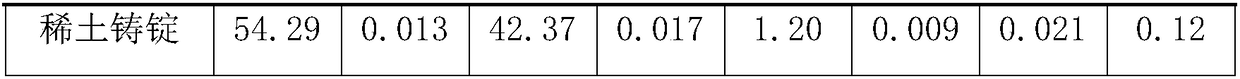

Embodiment 1

[0036] (1) Batching furnace:

[0037] Weigh 16KG of massive NdFeB waste, weigh 3KG of NdFeB superfine powder and 3KG of pretreated oil sludge respectively, and press the powder into blocks. The oil sludge has been pre-burned in a rotary kiln at a temperature of 300°C and a burning time of 30 minutes. When loading the furnace, first place 8KG blocky waste on the bottom of the induction heating furnace, then place 6KG pressed powdery waste in the middle of the furnace, and finally place the remaining 8KG blocky waste on the upper and surrounding sides of the furnace.

[0038] (2) Non-vacuum smelting reduction:

[0039] After all the materials are loaded into the furnace, induction heating and smelting is carried out under non-vacuum conditions, and the temperature is raised rapidly until the materials are completely melted, and then the temperature is controlled at about 1500-1800°C for 5-30 minutes, and then casting is carried out to obtain ferroalloy ingots and slag.

[0040...

Embodiment 2

[0055] (1) Batching furnace:

[0056] Weigh 10KG of bulk NdFeB waste, 2KG of rare earth metal, 3KG of NdFeB superfine powder and 3KG of pretreated oil sludge, and press the powder into blocks. The oil sludge has been pre-burned in a rotary kiln at a temperature of 300°C and a burning time of 30 minutes. When loading the furnace, first place 6KG blocky waste and 2KG rare earth metals on the bottom of the induction heating furnace, then place 6KG pressed powdery waste in the middle of the furnace, and finally place the remaining 4KG blocky waste on the upper and surrounding sides of the furnace .

[0057] (2) Non-vacuum smelting reduction:

[0058] After all the materials are loaded into the furnace, induction heating and smelting is carried out under non-vacuum conditions, and the temperature is raised rapidly until the materials are completely melted, and then the temperature is controlled at about 1500-1800°C for 5-30 minutes, and then casting is carried out to obtain ferro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com