High-adaptability solid polycarboxylate superplasticizer and polymerization preparation method of body of high-adaptability solid polycarboxylate superplasticizer

A bulk polymerization and adaptability technology, applied in bulk polymerization preparation of highly adaptable solid polycarboxylate superplasticizer, highly adaptable solid polycarboxylate superplasticizer, concrete admixture, polycarboxylate superplasticizer In the field of preparation, it can solve problems such as no guidance plan, and achieve the effects of wide adaptability, low production cost and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

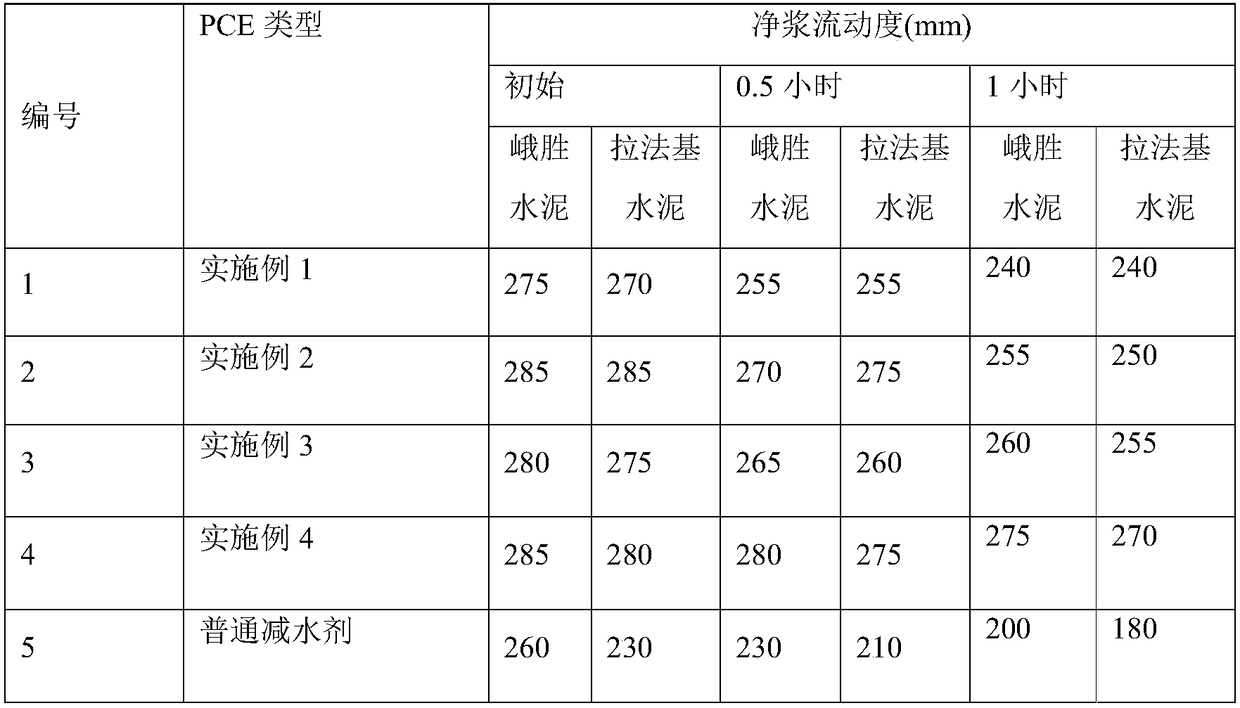

[0024] Example 1: The highly adaptable solid polycarboxylate water reducer described in the present invention is made from the following raw materials in parts by mass: 100 parts of allyl polyethylene glycol APEG monomer with a degree of polymerization of 33 , 21.6 parts of acrylic acid, 16.5 parts of maleic anhydride, 2.5 parts of styrene, 7.5 parts of unsaturated phosphonate monomer namely vinyl phosphonate diethyl ester, 1.48 parts of initiator namely azobisisobutyronitrile, the initiator accounts for all 1% of the total mass of the monomer.

[0025]The bulk polymerization preparation method of the highly adaptable solid polycarboxylate water-reducer comprises the following process steps: 1. Allyl polyethylene glycol APEG monomer (allyl polyoxyethylene glycol APEG) with a polymerization degree of 33 is prepared according to the above-mentioned mass fractions. Put 100 parts of polyethylene glycol) into the reaction kettle, heat up to 55°C and start stirring. After the allyl ...

Embodiment 2

[0026] Example 2: The highly adaptable solid polycarboxylate water reducer described in the present invention is made from the following raw materials in parts by mass: 120 parts of allyl polyethylene glycol APEG monomer with a degree of polymerization of 33 , 21.6 parts of acrylic acid, 25.6 parts of maleic anhydride, 5.5 parts of sodium styrene sulfonate, 8.5 parts of unsaturated phosphonate monomer, namely 2-hydroxyethyl methacrylate phosphate, the initiator, namely azodiisopropyl 1.9 parts of imidazoline hydrochloride, the initiator accounts for 1.05% of the total mass of all monomers.

[0027] The bulk polymerization preparation method of the highly adaptable solid polycarboxylate water reducer comprises the following process steps: ① put 120 parts of allyl polyethylene glycol APEG monomer with a polymerization degree of 33 into the In the reaction kettle, heat up to 55°C and start stirring. After the allyl polyethylene glycol APEG monomer is fully melted, continue to put...

Embodiment 3

[0028] Example 3: The highly adaptable solid polycarboxylate water reducer of the present invention is made from the following raw materials in parts by mass: 150 parts of allyl polyethylene glycol APEG monomer with a degree of polymerization of 33 , 25.3 parts of methacrylic acid, 29.6 parts of diallyl maleate, 6.6 parts of sodium styrene sulfonate, 9.6 parts of unsaturated phosphonate monomer namely 2-hydroxyethyl methacrylate phosphate, initiator 2.3 parts, the initiator is a combination of 1.7 parts of azoisobutylcyanoformamide and 0.6 parts of azobisisopropylimidazoline hydrochloride, and the initiator accounts for 1% of the total mass of all monomers.

[0029] The bulk polymerization preparation method of the highly adaptable solid polycarboxylate water reducer comprises the following process steps: ① put 150 parts of allyl polyethylene glycol APEG monomer with a polymerization degree of 33 into the In the reaction kettle, heat up to 60°C and start stirring. After the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com