Anti-ferroelectric ceramic material with high energy storage density and preparation method thereof

A technology of high energy storage density and ceramic materials, applied in the field of high energy storage density antiferroelectric ceramic materials and their preparation, can solve the problems of affecting the energy storage density and reducing the polarization strength of the antiferroelectric ceramics, so as to suppress volatilization, Avoid deviation, high energy storage density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The antiferroelectric ceramic material is composed of: Pb 0.97 La 0.02 (Zr 0.33 sn 0.55 Ti 0.12 )O 3 +5% SiO2 2

[0048] (1) Calculate the required Pb according to the composition of the above chemical formula 3 o 4 , La 2 o 3 , ZrO 2 , SnO 2 、TiO 2 Quality, mixed by wet ball milling method, according to the mass ratio of raw materials: balls: deionized water = 1:1.5:0.8, mixed for 6-8 hours, so that all components are mixed evenly. After drying, pass through a 30-mesh sieve, briquette in an air atmosphere, raise the temperature to 850°C at a rate of 2°C / min, and keep it warm for 3 hours. The synthetic composition is Pb 0.97 La 0.02 (Zr 0.33 sn 0.55 Ti 0.12 )O 3 powder (ceramic powder);

[0049] (2) The finely ground Pb 0.97 La 0.02 (Zr 0.33 sn 0.55 Ti 0.12 )O 3 Add ethanol (C 2 h 5 OH) after ultrasonic dispersion, mixed with tetraethyl silicate to form a mixed solution, according to the molar ratio of ceramic powder: tetraethyl silicate = 100...

Embodiment 2

[0056] The antiferroelectric ceramic material is composed of: Pb 0.97 La 0.02 (Zr 0.33 sn 0.55 Ti 0.12 )O 3 +3%SiO2 2

[0057] Repeat the preparation method of Example 1 according to the above formula, except that steps (2) and (3) are repeated twice before heat treatment. Then, a binder was added to granulate and a green body was prepared, and the obtained green body was sintered at 1220° C. and kept for 2 hours to obtain an antiferroelectric ceramic sample. The sintered ceramic material is smoothed, cleaned, dried, screen-printed with silver paste, dried again, put into a box-type electric furnace to burn silver, and the silver burning condition is 750°C for 30 minutes. An antiferroelectric ceramic sample covered with electrodes was obtained.

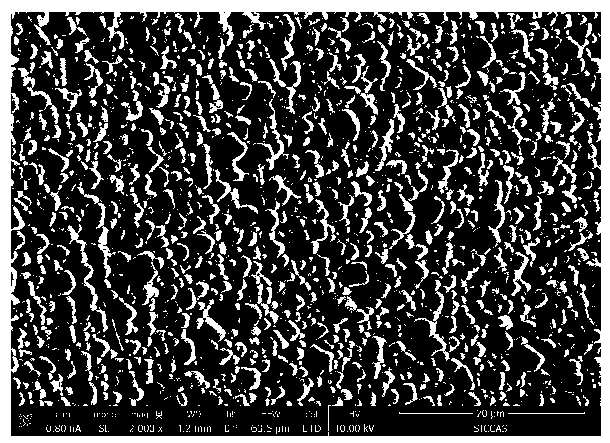

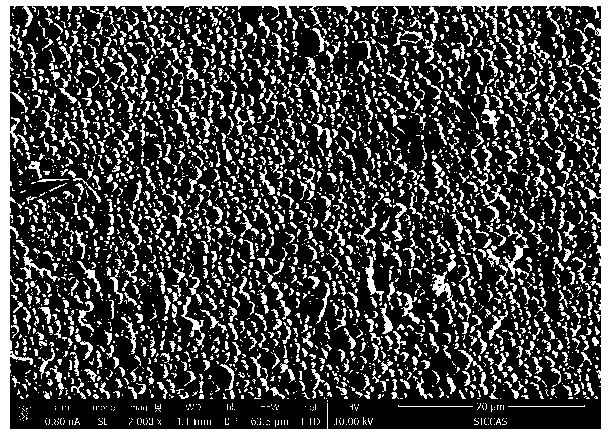

[0058] TEM observations were carried out on the coated powder samples, image 3 The surface micro-morphological structure diagram of the powder sample prepared in Example 2 is given. The surface SEM observation of the antife...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com