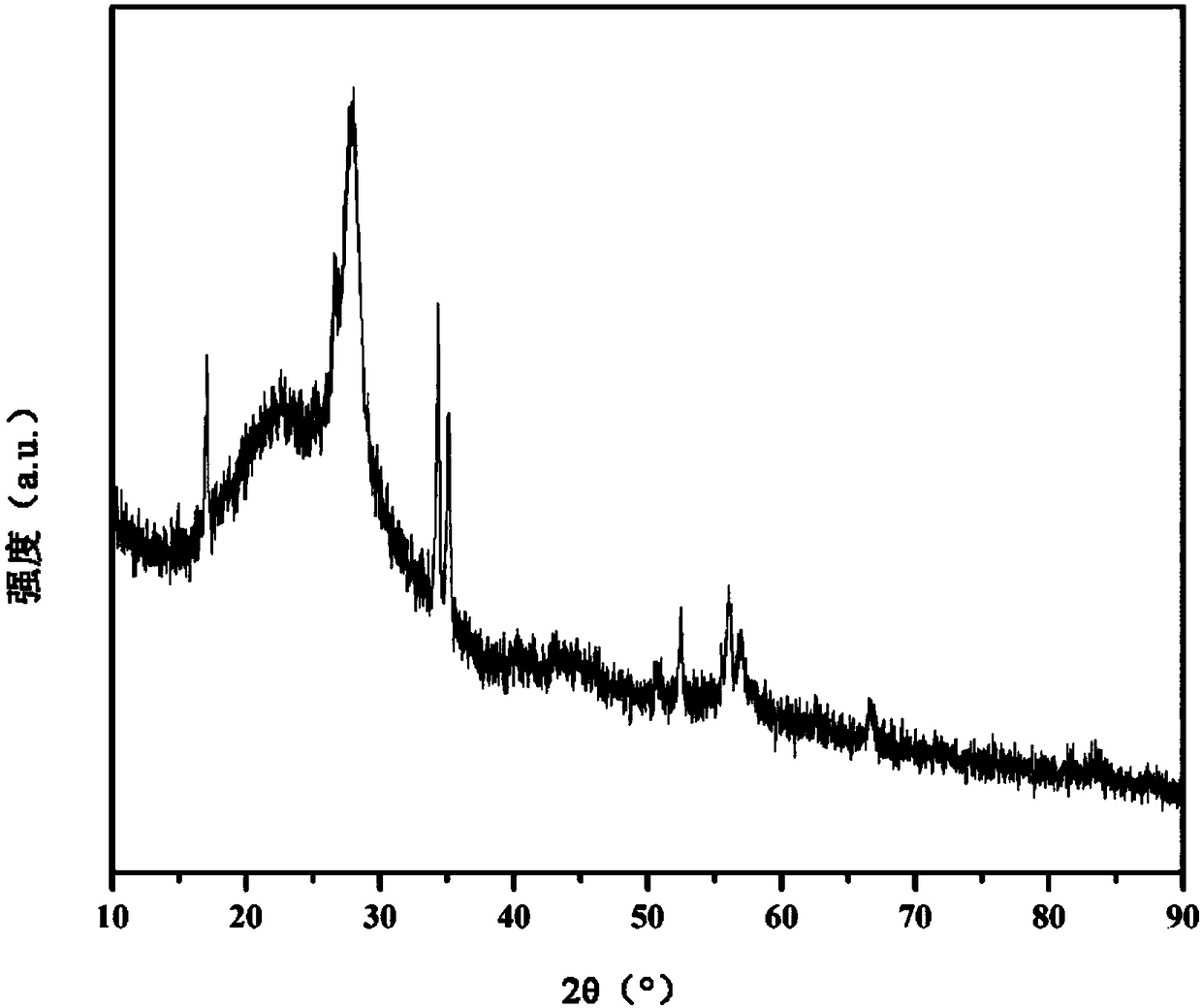

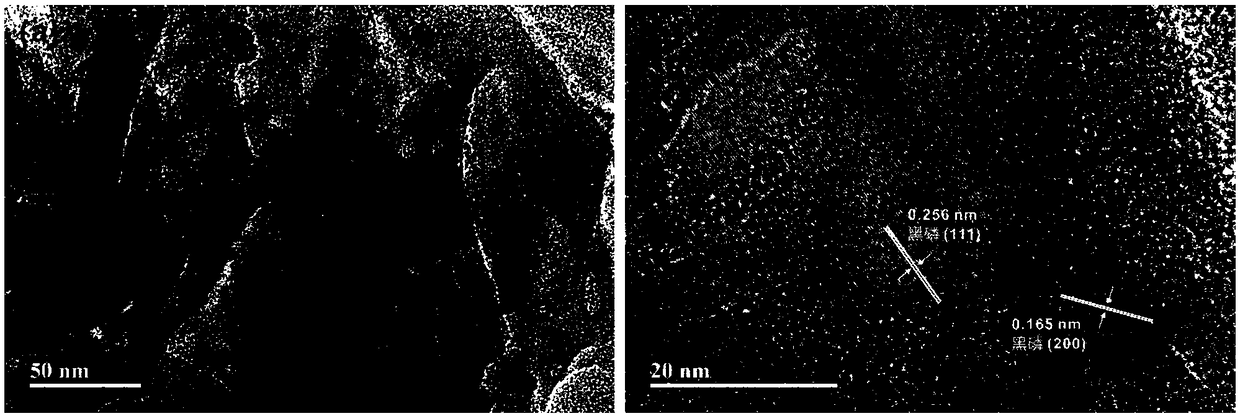

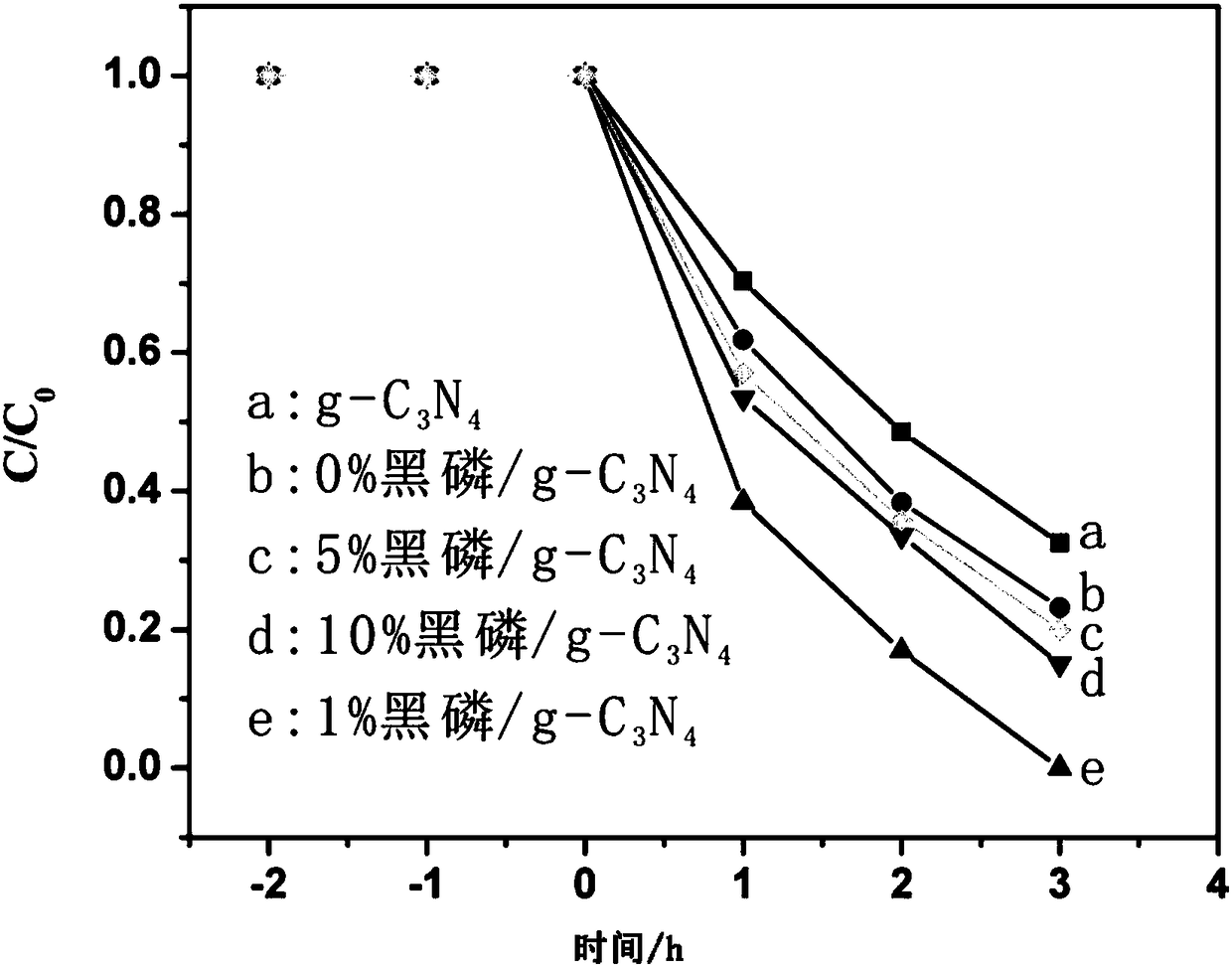

Black phosphorus/g-C3N4 composite visible light photocatalytic material as well as preparation method and application thereof

A photocatalytic material, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor photocatalytic efficiency and high recombination rate of photogenerated electrons and holes, Achieve the effects of low cost, improved photocatalytic efficiency, and simple preparation scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of black phosphorus / g-C 3 N 4 The preparation method of composite visible light photocatalytic material comprises the following steps:

[0037] 1) Weigh 10g of urea and place it in a corundum crucible, place it in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 2.2°C / min, then keep it warm for 120min, then cool down to room temperature within 120min, and grind to obtain g-C 3 N 4 ;

[0038] 2) Weigh 100 mg of black phosphorus crystals and grind them with a mortar, then add 100 mL of N-methylpyrrolidone solvent, conduct probe ultrasound, ice-water bath ultrasound, and then centrifuge with absolute ethanol to clean, take the precipitate at a centrifugal speed of 4000r / min, Black phosphorus powder can be prepared by vacuum drying; among them, the conditions of ultrasonic treatment of the probe are controlled as follows: ultrasonic power is 1000W, ultrasonic time is 5h; the conditions of ice-water bath ultrasonic treatment are c...

Embodiment 2

[0043] A kind of black phosphorus / g-C 3 N 4 The preparation method of composite visible light photocatalytic material comprises the following steps:

[0044] 1) Weigh 10g of urea and place it in a corundum crucible, place it in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 2.2°C / min, then keep it warm for 120min, then cool down to room temperature within 120min, and grind to obtain g-C 3 N 4 ;

[0045] 2) Weigh 100mg of black phosphorus crystals and grind them with a mortar, then add 50mL of N-methylpyrrolidone solvent, conduct probe ultrasound, ice-water bath ultrasound, and then centrifugally clean with absolute ethanol, take the precipitate at a centrifugal speed of 4000r / min, Black phosphorus powder can be prepared by vacuum drying; among them, the conditions of ultrasonic treatment of the probe are controlled as follows: ultrasonic power is 600W, ultrasonic time is 6h; the conditions of ice-water bath ultrasonic treatment are contr...

Embodiment 3

[0048] A kind of black phosphorus / g-C 3 N 4 The preparation method of composite visible light photocatalytic material comprises the following steps:

[0049] 1) Weigh 10g of urea and place it in a corundum crucible, place it in a muffle furnace, raise the temperature from room temperature to 550°C at a rate of 2.2°C / min, then keep it warm for 120min, then cool down to room temperature within 120min, and grind to obtain g-C 3 N 4 ;

[0050] 2) Weigh 100 mg of black phosphorus crystals and grind them with a mortar, then add 100 mL of N-methylpyrrolidone solvent, conduct probe ultrasound, ice-water bath ultrasound, and then centrifuge with absolute ethanol to clean, take the precipitate at a centrifugal speed of 4000r / min, Vacuum drying can prepare black phosphorus powder; among them, the conditions of ultrasonic treatment of the probe are controlled as follows: ultrasonic power is 500W, ultrasonic time is 7h; the conditions of ice-water bath ultrasonic treatment are controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com