Preparation method and application of silicon/nitrogen-doped graphene composite material for lithium ion battery

A nitrogen-doped graphene, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high preparation cost, complex process, difficult industrialization, etc., achieves low equipment requirements, simple synthesis route, High uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a silicon / nitrogen-doped graphene composite material, comprising the following steps:

[0031] (1) Weigh the nitrogen source: carbon source: silicon powder according to the mass ratio of 10: 1: (1-x), where 0≦x≦0.9; transfer the mixed powder to a ball mill jar, add absolute ethanol to The powder is in the form of a paste, and then ball-milled in a planetary ball mill for 1-10 hours, and the ball-milled mixture is dried at 60°C for 3-24 hours to obtain a precursor mixture;

[0032] (2) Transfer the mixed material obtained in step (1) to a vacuum tube furnace protected by an inert gas atmosphere, raise the temperature to 520-600°C at a heating rate of 1-15°C / min, and continue to heat at the same rate after 1-10 hours of heat preservation. Raise the temperature to 750-900°C, keep it warm for 1-10 hours, and then naturally cool to room temperature with the furnace to obtain a silicon / nitrogen-doped graphene composite material.

[0033] The nitrogen s...

Embodiment 1

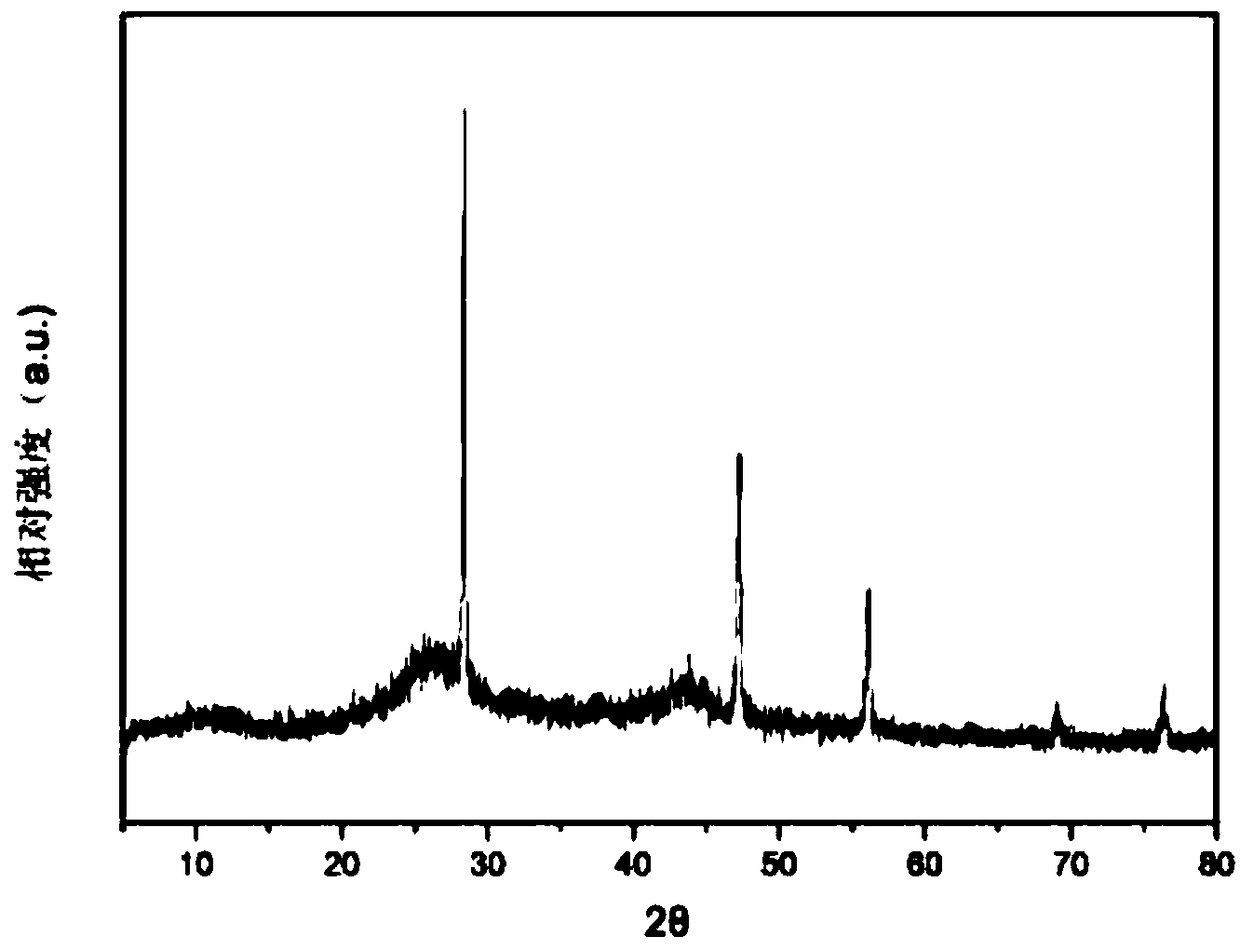

[0043] Example 1: Preparation method and characterization of silicon / nitrogen-doped graphene composite negative electrode material for lithium ion battery.

[0044] 1) The nitrogen source is a nitrogen-containing heterocyclic organic compound selected from melamine (C 3 N 3 (NH 2 ) 3 ) or dicyandiamide (C 2 h 4 N 4 ); Carbon source selects anhydrous glucose for use;

[0045] Weigh 3g melamine (C 3 N 3 (NH 2 ) 3 ), 0.3g of anhydrous glucose, 0.03g of 500nm silicon powder, transferred to a stainless steel ball mill jar, added 30ml of absolute ethanol to make the mixed powder into a paste, and after ball milling in a planetary ball mill for 6 hours, the mixture was transferred to a vacuum drying oven Dry at 60°C for 12 hours, then transfer the solid mixture to an OTF-1200X vacuum tube furnace, use argon as a protective gas to raise the temperature to 580°C at a rate of 2.5°C / min, and keep it for 4 hours with the same temperature rise Raise the temperature to 800°C, kee...

Embodiment 2

[0050] Embodiment 2: weigh 3g dicyandiamide (C 2 h 4 N 4 ), 0.3g anhydrous glucose, 0.03g 200nm silicon powder, transfer in the stainless steel ball mill tank, add 30ml absolute ethanol to make the mixed powder into a paste, after ball milling in the planetary ball mill for 6 hours, the mixture is transferred to vacuum drying Dry it in the oven at 60°C for 12 hours, then transfer the solid mixture to an OTF-1200X vacuum tube furnace, use argon as a protective gas to raise the temperature to 580°C at a rate of 2.5°C / min, and keep it for 4 hours. The heating rate is increased to 800°C, and after two hours of heat preservation, the furnace is cooled to room temperature, and the silicon / nitrogen-doped graphene composite material is obtained. Silicon exists in the graphene sheet in the form of simple silicon (JCPDS No. 27-1402), and the particle size is 100nm-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com