Environmental-friendly concrete additive and preparation method thereof

An environmentally friendly concrete and additive technology, applied in the field of building materials, can solve the problems of limited performance improvement capacity, large environmental pollution, and single performance of concrete, and achieve the effects of improving compatibility and dispersibility, small environmental pollution, and large performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

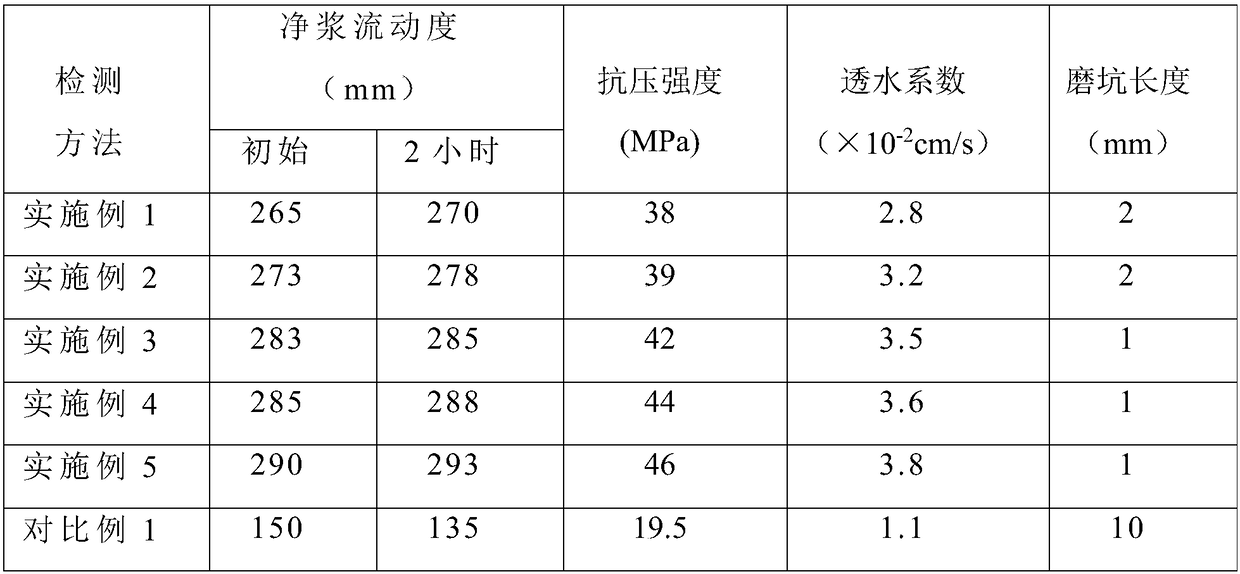

Examples

Embodiment 1

[0035] An environment-friendly concrete additive comprises the following components in parts by weight: 12 parts of organically modified montmorillonite, 1 part of organic boron fiber, 1 part of polyether phosphate amine salt, and 1 part of surfactant.

[0036] The preparation method of the organically modified montmorillonite comprises the steps of: dispersing 30 g of montmorillonite in 100 g of ethanol, and adding 5 g of silane coupling agent KH560 to it, stirring and reacting at 30° C. for 2 hours, and then adding Add 20 g of chitosan, reflux and stir at 70°C for 6 hours, then remove the solvent by rotary evaporation, wash with ethanol for 3 times, and place in a vacuum oven for 12 hours at 70°C.

[0037] The preparation method of described polyether phosphate amine salt, comprises the steps:

[0038] 1) Dissolve 20g of bis(2-aminoethyl)hydrogen phosphate in 100g of N-methylpyrrolidone, add 5g of chlorinated polyether to it, stir and react at 50°C for 6 hours, and then prec...

Embodiment 2

[0046] An environment-friendly concrete additive comprises the following components in parts by weight: 13 parts of organically modified montmorillonite, 2 parts of organic boron fiber, 1 part of polyether phosphate amine salt, and 2 parts of surfactant.

[0047] Preferably, the preparation method of the organically modified montmorillonite comprises the steps of: dispersing 35 g of montmorillonite in 120 g of isopropanol, and adding 6 g of silane coupling agent KH560 to it, and stirring and reacting at 32° C. for 2.5 hour, then add chitosan 22g therein, reflux and stir reaction at 72°C for 6.5 hours, then rotary evaporate to remove the solvent, and wash 4 times with ethanol and place in a vacuum drying oven at 73°C for 13 hours.

[0048] The preparation method of described polyether phosphate amine salt, comprises the steps:

[0049] 1) Dissolve 23g of bis(2-aminoethyl)hydrogen phosphate in 120g of dimethyl sulfoxide, add 6g of chlorinated polyether to it, stir and react at 5...

Embodiment 3

[0057] An environment-friendly concrete additive comprises the following components in parts by weight: 13 parts of organically modified montmorillonite, 3 parts of organic boron fiber, 2 parts of polyether phosphate amine salt, and 3 parts of surfactant.

[0058] The preparation method of the organically modified montmorillonite comprises the following steps: dispersing 40 g of montmorillonite in 130 g of dichloromethane, and adding 7 g of silane coupling agent KH560 therein, stirring and reacting at 34° C. for 3 hours, and then Add 25g of chitosan therein, reflux and stir the reaction at 75°C for 7 hours, then remove the solvent by rotary evaporation, wash with ethanol for 5 times, and place in a vacuum drying oven for 13.5 hours at 76°C.

[0059] The preparation method of described polyether phosphate amine salt, comprises the steps:

[0060] 1) Dissolve 25g of bis(2-aminoethyl)hydrogen phosphate in 135g of N,N-dimethylformamide, add 7g of chlorinated polyether to it, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com