Ultra-light special optical cable

An ultra-light and special technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of inconvenient and fast construction, large bending radius, and large volume, and achieve the advantages of easy transportation and construction, reduced bending radius, and saving storage space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

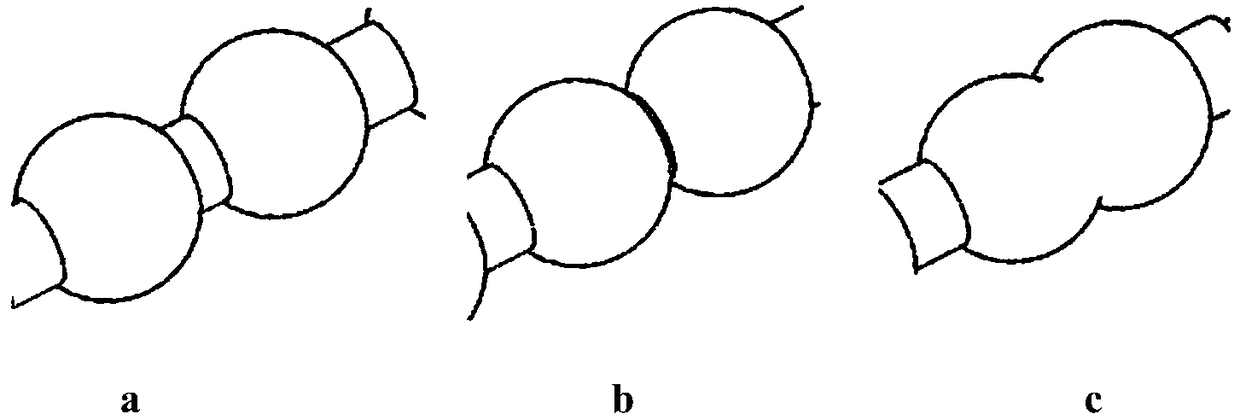

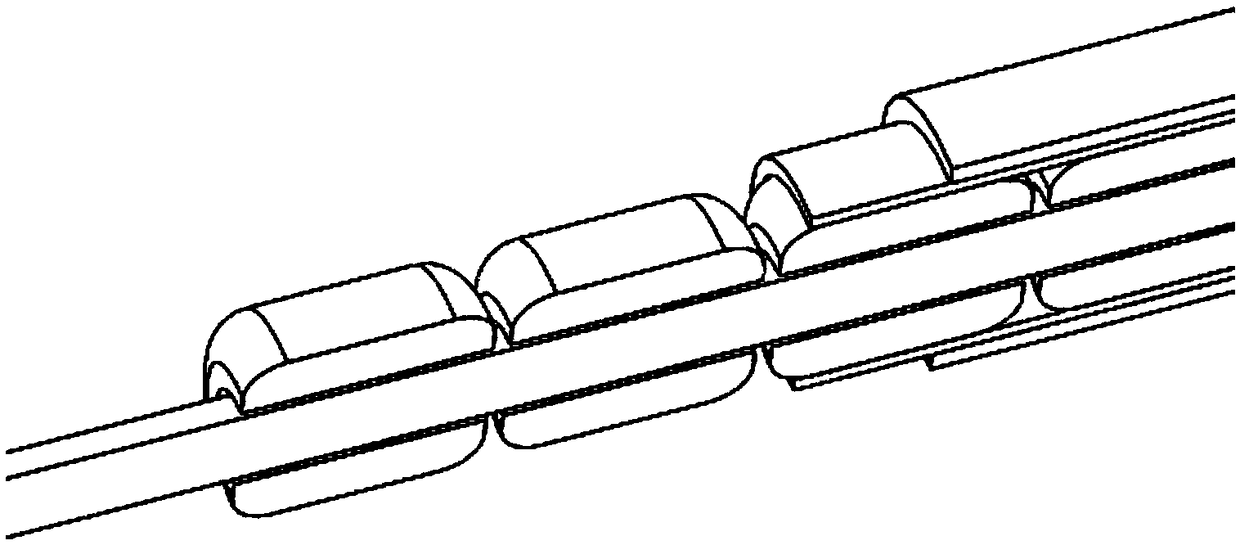

[0027] Such as figure 2 As shown in b, an ultra-light special optical cable includes an outer sheath 1, a tensile layer 2, a compression layer 4 and a fiber core 6 from the outside to the inside, and adjacent layers are arranged in close contact with each other; the outer sheath The thickness of layer 1 is 0.5 mm, and the material used is TPU. The tensile layer 2 is made of Kevlar material. The outer diameter of the compressive layer 4 is 2 mm, which is composed of several tangent spheroids.

Embodiment 2

[0029] Such as figure 2 As shown in c, an ultra-light special optical cable includes an outer sheath 1 from the outside to the inside, a tensile layer 2, a compression layer 4 and a fiber core 6, and adjacent layers are arranged in close contact with each other; the outer sheath The thickness of layer 1 is 0.5 mm, and the material used is TPU. The tensile layer 2 is made of Kevlar material. The outer diameter of the compressive layer 4 is 2 mm, which is composed of several intersecting spheroids.

Embodiment 3

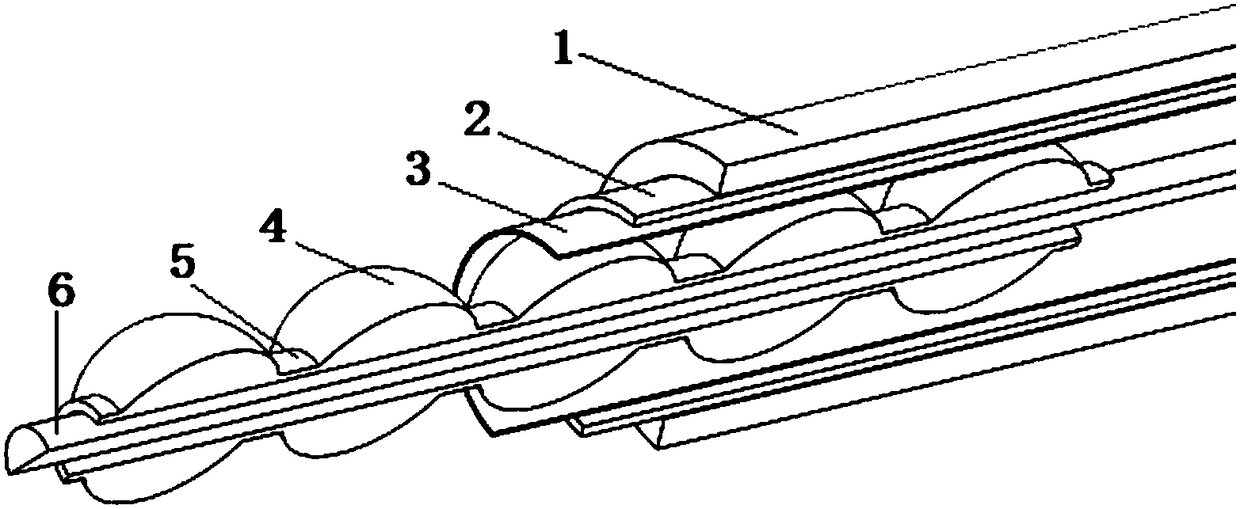

[0031] Such as figure 1 and figure 2 As shown in a, an ultra-light special optical cable includes an outer sheath 1, a tensile layer 2, buffer layers 3, 4 and a fiber core 6 from outside to inside; the thickness of the outer sheath 1 is 1 mm, and the material used It is PE, and the tensile layer 2 is made of aramid fiber. The outer diameter of the compressive layer 4 is 3mm, and it is composed of several spherical bodies separated by a certain distance. Deformed connection part 5, the diameter of the connection part 5 is 2mm, the buffer layer 3 is made of rubber material, and the rubber buffer layer is set to buffer the extrusion between adjacent spheres when the optical cable is bent, and at the same time, it can also reduce the repeated compression of the compression layer. Bending causes abrasion of the tensile layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com