Concrete-filled steel pipe special-shaped column-concealed beam floor slab fabricated system adopting Z-shaped connecting

A technology of steel pipe concrete and reinforced concrete, which is applied to floors, building components, buildings, etc., can solve the problems of unfavorable space flexible layout, increased cost, and large total floor thickness, so as to achieve flexible building space layout, convenient maintenance and renovation, and reduce Effect of Small Overall Thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

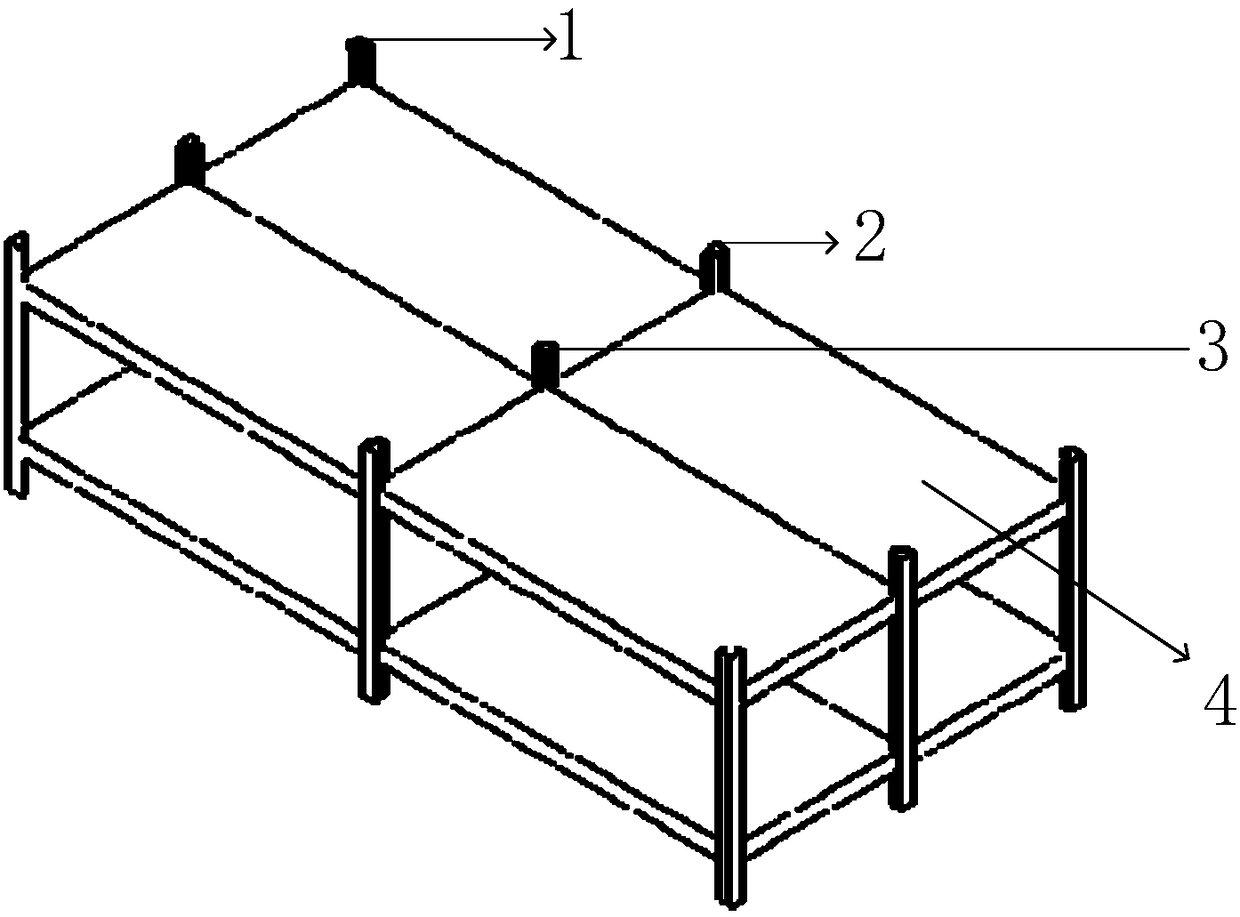

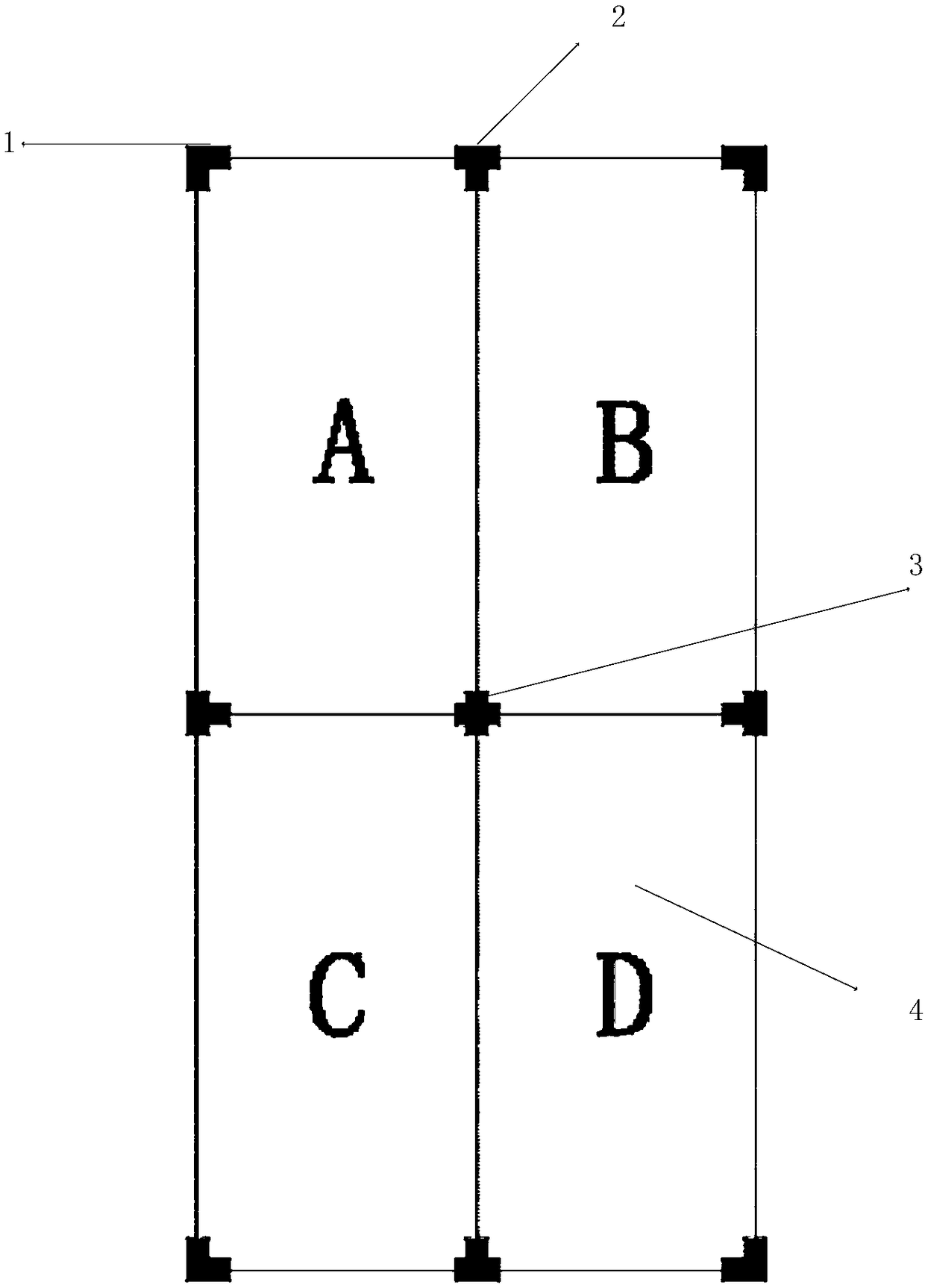

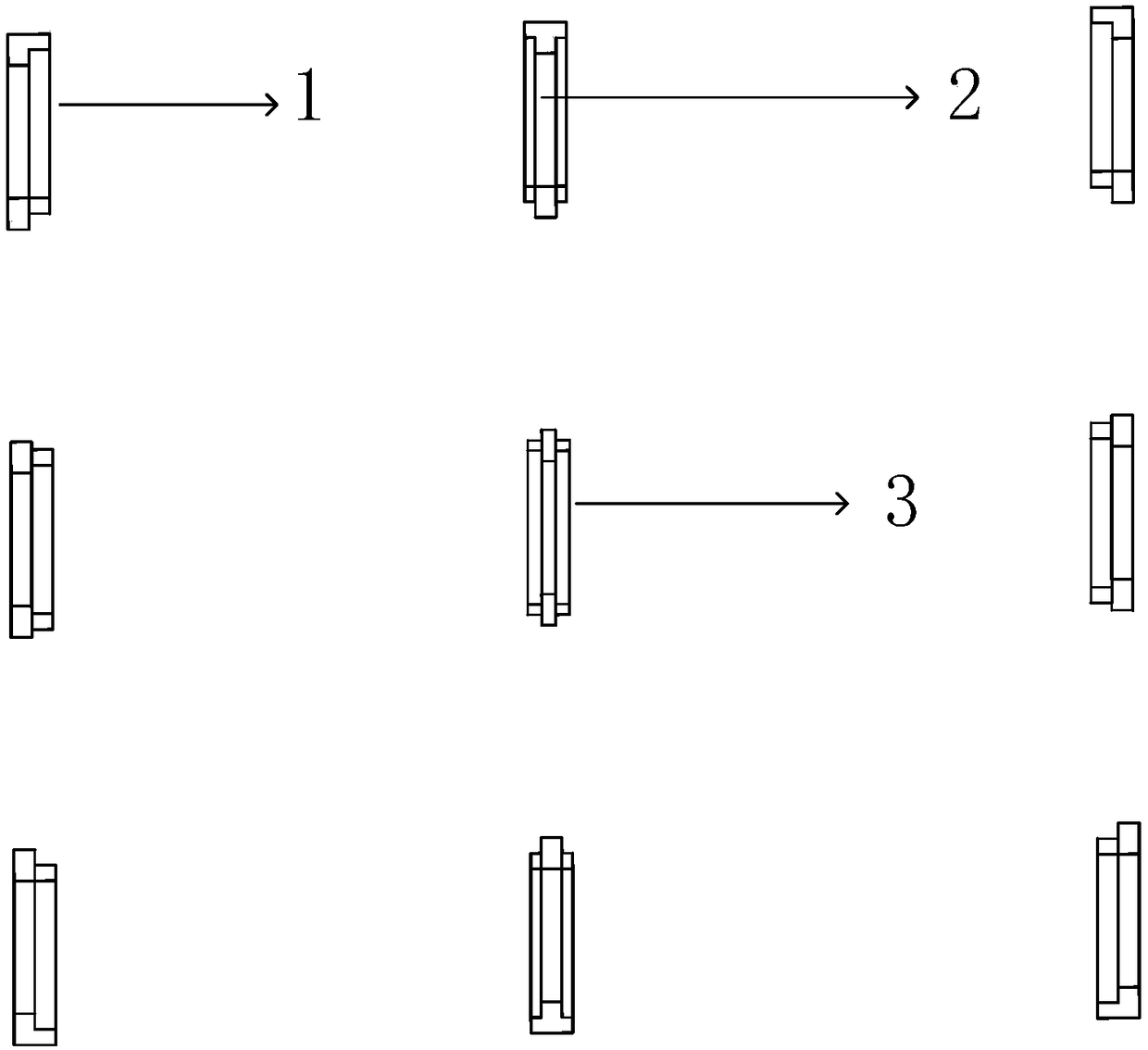

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings. The embodiments described below with reference to the accompanying drawings are examples and are intended to explain the present invention, but should not be construed as limiting the present invention.

[0032] The specific assembly method of the Z-type connected steel pipe concrete special-shaped column-invisible beam floor slab assembly system proposed by the present invention is as follows: first, the main beam I (5), the main beam II (6), and the main beam with the web holes prefabricated in the factory Ⅲ(7) and the main beam Ⅳ(8) are spliced by four triangular connecting plates (10) in pairs to form the frame of the invisible beam floor module. parallel to the short side. Next, arrange horizontal distribution bars (12) and longitudinal bars (13) at the lower part of the steel beam, and pour 40mm-100mm prefabricated concrete at the position of the bars (11) to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com