Assembling workbench for engine harnesses

A technology for assembling workbenches and engines, applied to workbenches, manufacturing tools, etc., can solve the problems of low assembly efficiency of engine wiring harnesses, confusion of wires, and prone to errors, and achieve the effect of improving assembly speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

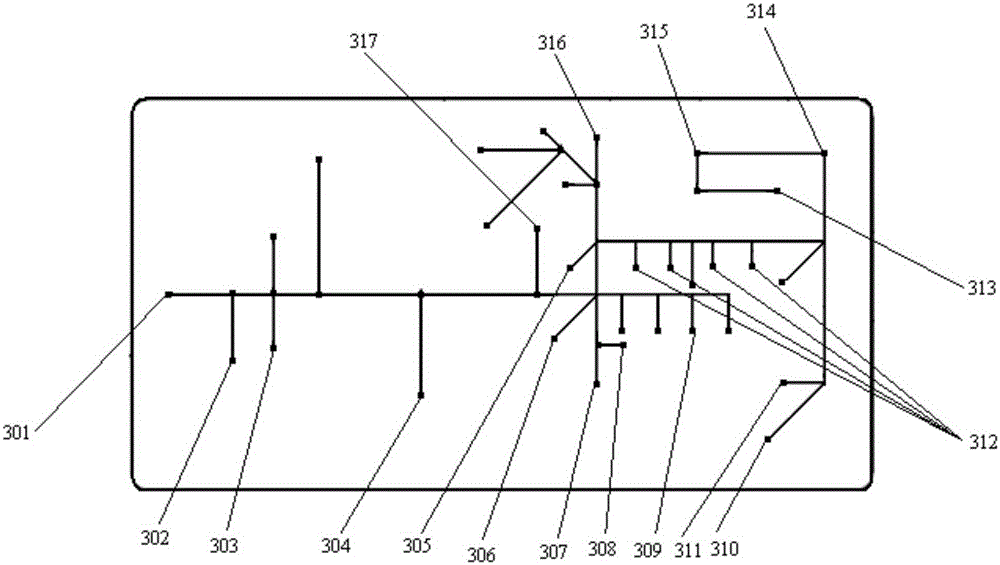

[0036] An embodiment of the present invention provides an engine wiring harness assembly workbench, see figure 1 and combine figure 2 , the engine wiring harness assembly workbench includes: an assembly panel 1 and an assembly panel bracket 2; On the bracket 201, the other end is fixed on the first horizontal bracket 202 through the fixing part 4; the angle between the assembly panel 1 and the horizontal direction is less than 90°; the wire fixing part 3 is arranged on the assembly panel 1.

[0037] The working principle of the engine wire harness assembly workbench provided by the embodiment of the present invention is as follows: according to the position of each sensor in the engine electric control schematic diagram, the corresponding wire fixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com