Low dielectric constant polyimide porous thin film and preparation method thereof

A technology of polyimide film and low dielectric constant, which is applied in the field of low dielectric constant polyimide porous film and its preparation, can solve the problems of complicated operation process, complicated technology, expensive raw materials and the like, and achieves simplified film production. The steps, the operation process and the technology are simple, and the raw materials are cheap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 3 mg of polyimide and 0.3 mg of dodecyldimethylammonium bromide in 5 mL of dichloromethane to prepare a polyimide organic solution, and mix 1 mL of this polyimide organic solution with 50 µL Mix with deionized water, sonicate for 10 minutes, filter with a 220nm organic filter, take 200 µL of the filtrate and pour it on a clean glass substrate at a temperature of 30°C and a humidity of 53%, and wait for the dichloromethane and water to volatilize After completion, an ordered polyimide porous membrane with a pore diameter of about 3.6 µm and a pore depth of about 7.8 µm was prepared.

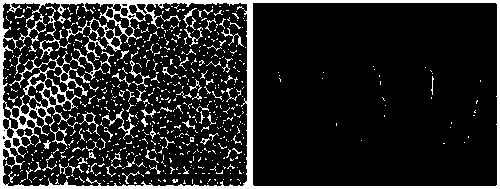

[0030] attached figure 1 It is a scanning electron microscope picture of the prepared polyimide porous membrane. It can be seen that in the polyimide porous membrane, the pore size presents the characteristics of multi-level distribution, including larger holes in the upper layer and smaller holes in the bottom. The large pores in the upper layer are uniform in size and arranged i...

Embodiment 2

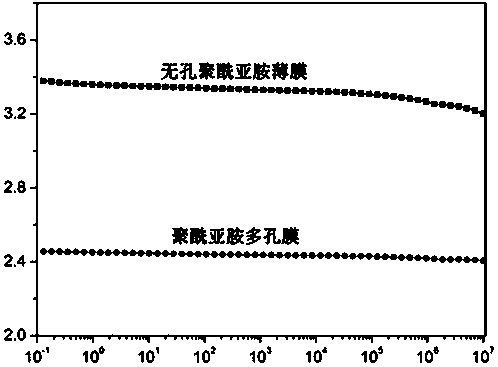

[0033] As shown in Example 1, other conditions remain unchanged, the mass of polyimide is changed to 5.5 mg, the preparation of polyimide organic solution is carried out, and then the same operation steps are repeated to prepare macropores with a diameter of about 3.5 μm Compared with the non-porous polyimide film, the dielectric constant of the polyimide porous film is reduced from 3.20 to 2.64, which is a decrease of 17.42%.

Embodiment 3

[0035] As shown in Example 1, other conditions remain unchanged, the mass of polyimide is changed to 10 mg, the preparation of polyimide organic solution is carried out, and then the same operation steps are repeated to prepare macropores with a diameter of about 2.8 μm Compared with the non-porous polyimide film, the dielectric constant of the polyimide porous film is reduced from 3.20 to 2.72, which is a decrease of 14.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com