Cotton-mass-shaped cobalt phosphate sphere and preparation method thereof

A technology of cobalt phosphate balls and cobalt phosphate nanometers, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of cobalt phosphate and other problems, avoid poor dispersion, high yield, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 Add 10mL of water and 40mL of absolute ethanol to 4mmol of hexamethylenetetramine and 10mmol of sodium dihydrogen phosphate dihydrate, and stir well to obtain a uniform solution;

[0030] 1.2 Add 2 mmol of cobalt nitrate hexahydrate to the homogeneous solution in 1.1, and stir until the cobalt nitrate is completely dissolved to obtain a mixed solution;

[0031] 1.3 Move the mixed solution obtained in 1.2 into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction, the temperature is 110°C, the hydrothermal time is 3h, and the reaction solution is obtained after the reaction;

[0032] 1.4 Centrifuge, wash and dry the reaction solution to obtain the precursor;

[0033] 1.5 Raise the temperature of the precursor to 400°C at a rate of 5°C / min and keep it warm for 1 hour to obtain cobalt phosphate spheres.

[0034] figure 1 is the X-ray diffraction pattern of the obtained sample, as can be seen from the figure, the obtained material is pure cobalt phosphat...

Embodiment 2

[0036] 2.1 Add 10mL of water and 40mL of absolute ethanol to 8mmol of hexamethylenetetramine and 10mmol of sodium dihydrogen phosphate dihydrate, and stir well to obtain a uniform solution;

[0037] 2.2 Add 2 mmol of cobalt nitrate hexahydrate to the homogeneous solution in 2.1, and stir until the cobalt nitrate is completely dissolved to obtain a mixed solution;

[0038] 2.3 Move the mixed solution obtained in 2.2 into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction, the temperature is 110°C, the hydrothermal time is 3h, and the reaction solution is obtained after the reaction;

[0039] 2.4 Centrifuge, wash and dry the reaction solution to obtain the precursor;

[0040] 2.5 Raise the temperature of the precursor to 400°C at a rate of 5°C / min and keep it warm for 1 hour to obtain cobalt phosphate spheres.

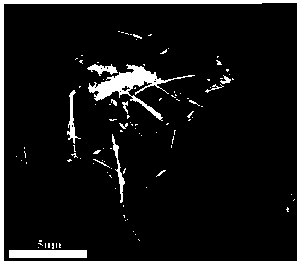

[0041] The morphology of the obtained cobalt phosphate balls is as follows image 3 As can be seen from the figure, the structure of the product obtai...

Embodiment 3

[0043] 3.1 Add 10mL of water and 40mL of absolute ethanol to 6mmol of hexamethylenetetramine and 10mmol of sodium dihydrogen phosphate dihydrate, and stir evenly to obtain a uniform solution;

[0044] 3.2 Add 2 mmol of cobalt nitrate hexahydrate to the homogeneous solution in 3.1, and stir until the cobalt nitrate is completely dissolved to obtain a mixed solution;

[0045] 3.3 Move the mixed solution obtained in 3.2 into a polytetrafluoroethylene-lined autoclave for hydrothermal reaction, the temperature is 110° C., the hydrothermal time is 3 hours, and the reaction solution is obtained after the reaction;

[0046] 3.4 Centrifuge, wash and dry the reaction solution to obtain the precursor;

[0047] 3.5 Raise the temperature of the precursor to 400°C at a rate of 5°C / min and keep it warm for 1 hour to obtain cobalt phosphate spheres.

[0048] The morphology of the obtained cobalt phosphate balls is as follows Figure 4 As can be seen from the figure, the structure of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com