Oxidized graphene doped mesoporous silicon film, preparation method thereof and application of film

A mesoporous silicon and graphene technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as poor selectivity, secondary pollution, difficult continuous operation of powder materials, etc. Achieve the effects of easy recycling, energy saving, and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043](1) Take 10 g of commercially available cotton and place it in 150 mL of sulfuric acid solution with a mass fraction of 40%, then stir and react at 35°C for 2 hours, then transfer it to a beaker, dilute it to 600 mL with distilled water, then let it stand overnight and pour Remove the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous substance, transfer the suspension to a dialysis membrane for dialysis for 3 to 5 days, adjust the pH to 2.4, then sonicate for 10 minutes, and dilute to obtain nanocellulose crystals ( NCC) for use;

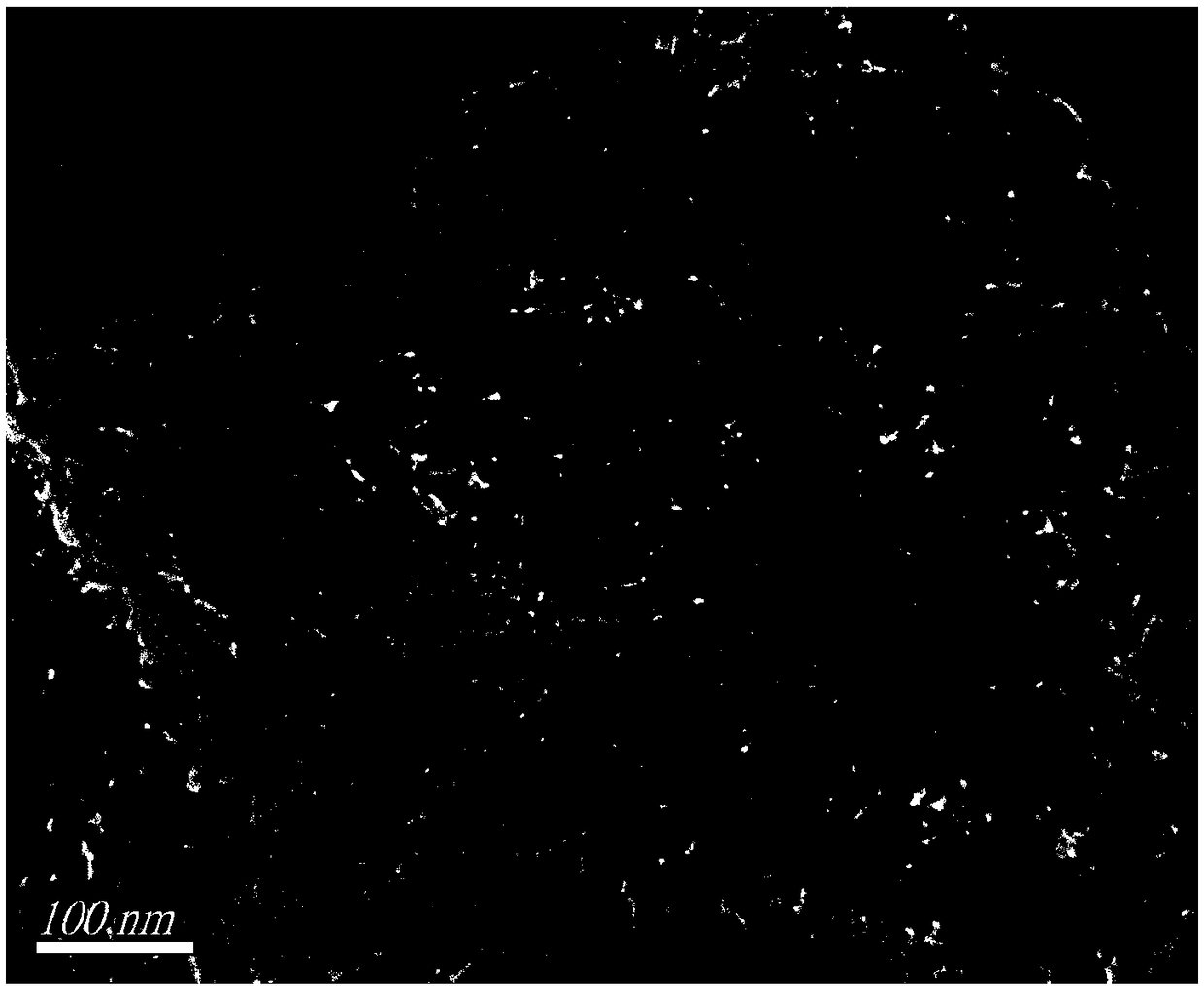

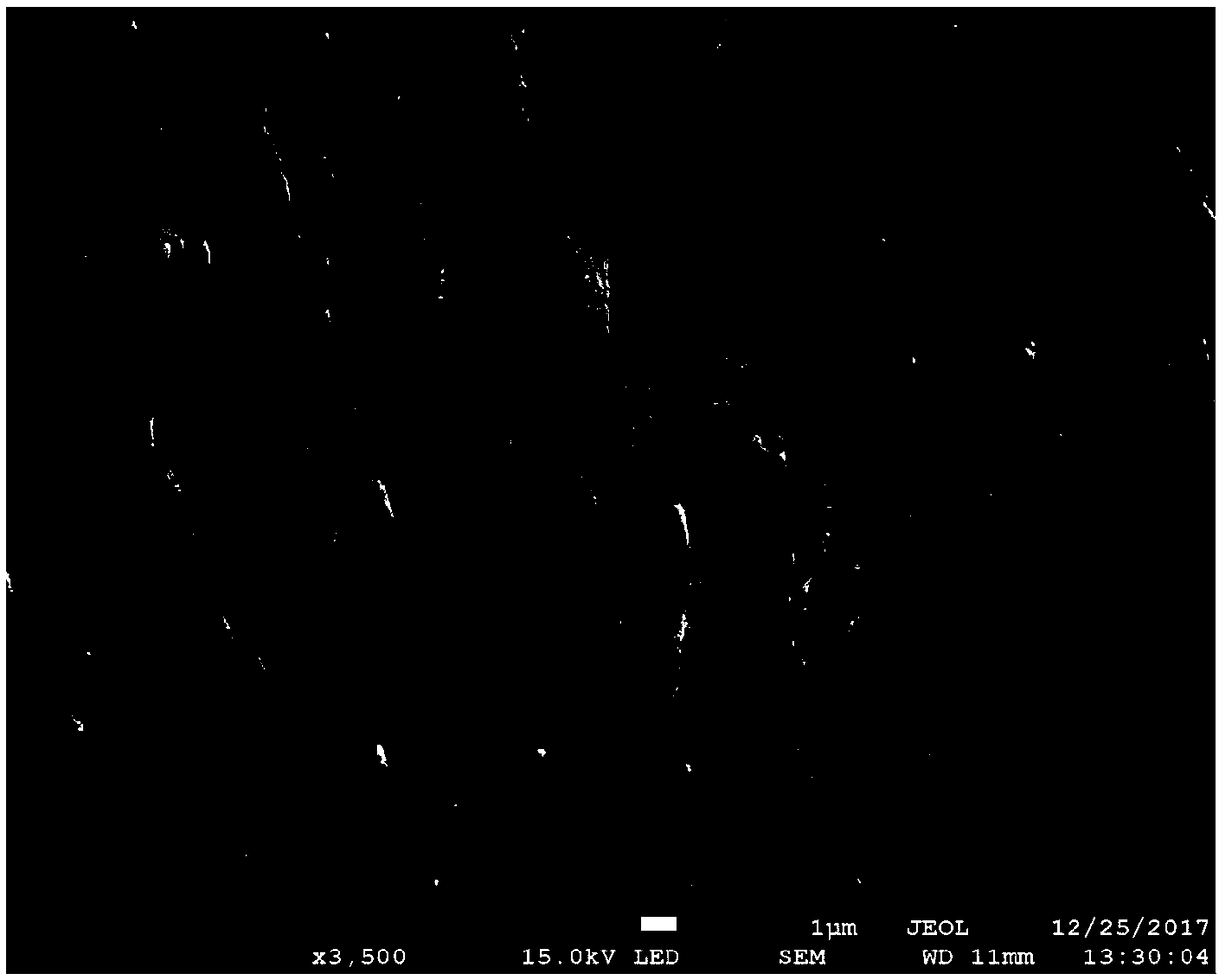

[0044] (2) Pipette 10 mL of the NCC obtained in step (1), sonicate for 20 min, place it in a round bottom flask, add 100 mg of glucose and 100 μL of graphene oxide (GO), stir for 1 h, and then add 40 μL of diethylphosphonoethyl A mixed solution of triethoxysilane (PETES) and 410 μL tetraethyl silicate (TEOS), stirred at 50°C for 2 hours, poured into a watch glass and dried in a water bath at ...

Embodiment 2

[0058] (1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 50wt%, then stir and react at 45°C for 3h, then transfer it to a beaker, dilute to 600mL with distilled water, then let stand overnight to separate layers, pour Remove the supernatant, centrifuge the precipitate, wash with distilled water three times to remove the mixed solution attached to the precipitate, transfer the precipitate to a dialysis membrane for dialysis for 3 to 5 days, adjust the pH to 2.4 within half an hour, and then sonicate for 20 minutes to dilute to obtain nanofibers Plain crystal (NCC) for use;

[0059] (2) Pipette 10 mL of nanocellulose crystals (NCC) obtained in step (1) and sonicate for 20 min, place them in a round bottom flask, add 150 mg of glucose and 250 μL of graphene oxide (GO), stir for 2 h, and then add 50 μL of A mixed solution of ethylphosphonoethyltriethoxysilane (PETES) and 400 μL tetraethyl silicate (TEOS), stirred ...

Embodiment 3

[0072] (1) Get 10g of commercially available cotton and place it in 150mL mass fraction of 60wt% sulfuric acid solution, then stir and react at 55°C for 4 hours, then transfer it to a beaker, dilute to 600mL with distilled water, then let it stand overnight for stratification, Pour off the supernatant, centrifuge the precipitate, wash with distilled water three times to remove the mixed solution attached to the precipitate, transfer the precipitate to a dialysis membrane for dialysis for 3 to 5 days, adjust the pH to 2.4, then sonicate for 10 minutes, and dilute to obtain nanocellulose crystals (NCC) for use;

[0073] (2) Pipette the NCC obtained from the treatment in step (1), pipette 10mL after ultrasonication for 20min, place it in a round bottom flask, add 200mg glucose and 500μL graphene oxide (GO), stir for 3h, then add 60μL diethyl A mixed solution of phosphoethyltriethoxysilane (PETES) and 390 μL tetraethyl silicate (TEOS), stirred at 70°C for 3 hours, poured into a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com