Automatic spring rotary-cutting and inserting machine for preparation of film-suspended insulating glass film stretching frame

A technology of stretching film frame and spring inserting machine, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of profile damage, high labor intensity, complicated movements, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

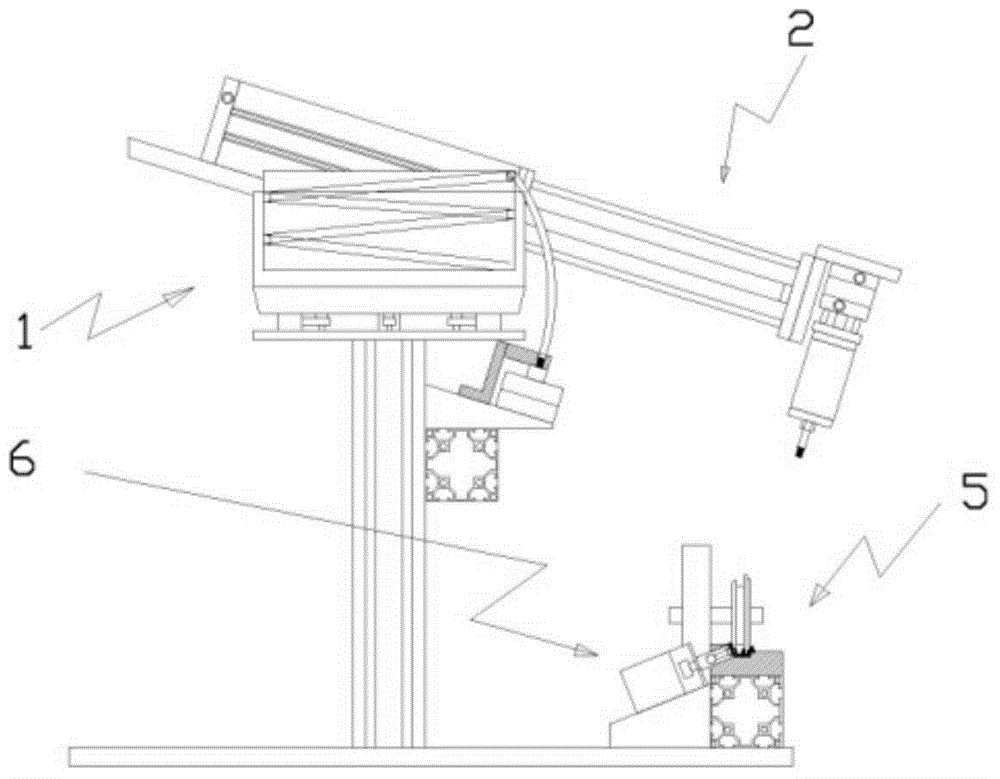

[0048] Such as figure 1 , 2 As shown in and 3, the automatic rotary cutting inserting spring machine for preparing the film-suspending hollow glass stretch film frame, on the flat square work table made of steel plate, the front end edge is equipped with a backing mechanism (5), which is close to the backing mechanism (5 ) is installed at the right end behind the rotary cutting mechanism (4), the left end is equipped with a frame-moving mechanism (6), the upper part behind the rotary-cutting mechanism (4) is installed with a spring removal mechanism (2), and behind the frame-moving Spring mechanism (1), spring feeding mechanism (3) is installed in the middle of spring feeding mechanism (1) and taking spring mechanism (2) (below taking spring mechanism (2)). Spring feeding mechanism (1), spring taking mechanism (2) and spring sending mechanism (3) are all installed on the fixed mount on the workbench.

[0049] (Note: Unless otherwise specified, the components involved in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com