Hydraulic synchronous distribution motor with unloading function

A hydraulic synchronous, shunt motor technology, applied in the direction of servo motor components, fluid pressure actuators, servo meter circuits, etc., can solve the problems of energy consumption, uneconomical, time-consuming, etc., to reduce heat, improve efficiency, save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

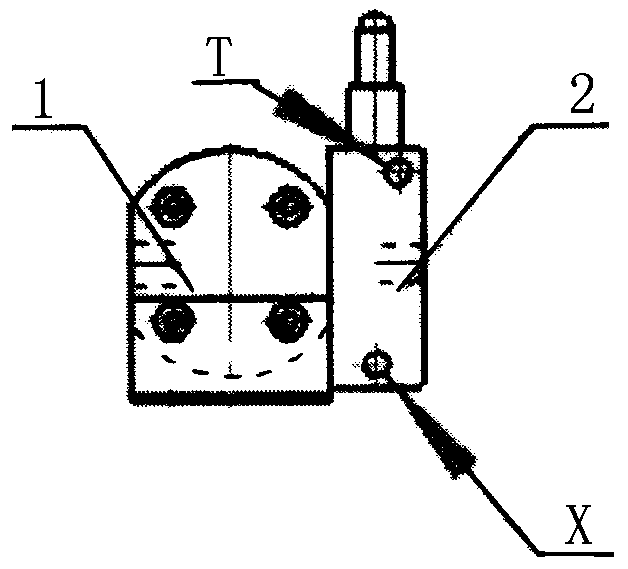

[0017] figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention takes a four-way gear type hydraulic synchronous motor as an example, including a hydraulic synchronous motor body 1 and an externally controlled valve group 2, the externally controlled valve group is installed on the output end of the hydraulic synchronous motor body, and the externally controlled valve group There are external control ports X and T on the group. The hydraulic synchronous motor body is composed of four hydraulic motors that are independent on the oil circuit and rigidly connected together on the transmission. The input ends of the four hydraulic motors 6 are connected together, while the output ends are independent. On the hydraulic synchronous motor body 1, there are two connected oil inlets P1, P2 and four independent oil outlets A1, A2, A3 , A4, oil inlets and oil outlets are respectively provided on the four hydraulic motors.

[0018] The externally controlled valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com