A dye self-polymerized thin film random laser and its preparation method

A random laser and self-aggregation technology, applied in the laser field, can solve the problem of high random laser threshold, and achieve the effects of lowering the preparation cost, lowering the threshold and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

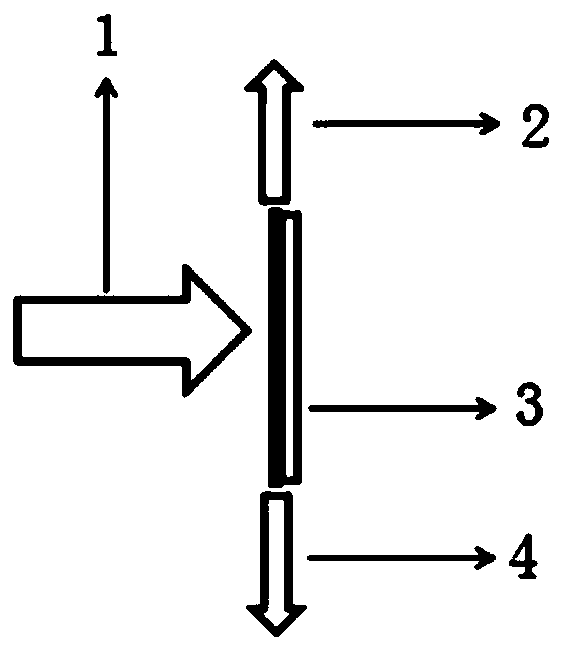

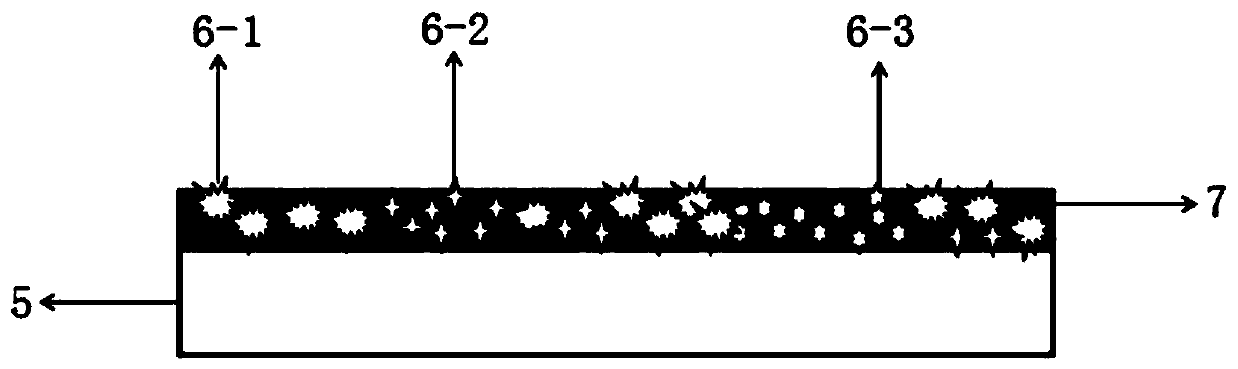

[0032] Such as figure 1 with 2 As shown, a dye self-polymerization thin-film random laser includes an external pump light 1 and a thin-film sample 3; the thin-film sample is composed of a glass negative 5 and a PDMS thin film 7, and the glass negative 5 and the PDMS thin-film 7 together form a leaky waveguide structure; the PDMS film 7 contains spontaneously aggregated PM597 dye micro-nano crystals 6-1, 6-2, 6-3; the dye micro-nano crystals are formed by spontaneous aggregation of dye molecules, and this micro-nano crystals are formed in It acts as a scattering medium and a gain medium at the same time during the random laser emission process. At the same time, the leaky waveguide structure jointly formed by the glass substrate 5 and the PDMS thin film 7 confines the pump light and provides optical feedback for the formation of random laser light. The green light with a wavelength of 532nm output by the Nd:YAG laser passes through the external pump light path, and finally fo...

Embodiment 2

[0034] Preparation method of dye self-polymerized thin film random laser:

[0035] (1) Mix PDMS prepolymer A and toluene solvent in a mass ratio of 1:6, and stir with a magnetic stirrer for 20 minutes to make the solution evenly mixed;

[0036] (2) Add PM597 dye molecules to the mixed solution, and ultrasonicate for 10min-20min;

[0037] (3) After ultrasonication, add PDMS curing agent B, the mass ratio of PDMS curing agent B and PDMS prepolymer A is 1:8, stir for 1 hour; mix the solution evenly;

[0038](4) Add the mixed solution obtained in step (3) evenly dropwise onto a pre-cleaned 2cm*3cm glass negative, and let stand overnight to remove air bubbles and volatilize the toluene.

[0039] (5) Heat the glass negative film dripped with the mixed solution overnight at 70°C for 8 hours to evaporate excess toluene, and solidify the mixed solution to form a film on the glass negative film to prepare a PDMS film sample.

[0040] (6) The thin film sample prepared in step (5) is co...

Embodiment 3

[0043] Preparation method of dye self-polymerized thin film random laser:

[0044] (1) Mix PDMS prepolymer A and toluene solvent in a mass ratio of 2:3, stir with a magnetic stirrer for 40 minutes, and mix the solution evenly;

[0045] (2) Add PM597 dye molecules to the mixed solution, and sonicate for 20 minutes;

[0046] (3) After ultrasonication, add PDMS curing agent B, the mass ratio of PDMS curing agent B and PDMS prepolymer A is 1:10, stir for 2 hours; mix the solution evenly;

[0047] (4) Add the mixed solution obtained in step (3) evenly dropwise onto a pre-cleaned 2cm*3cm glass negative, and let stand overnight to remove air bubbles and volatilize the toluene.

[0048] (5) Heat the glass negative film dripped with the mixed solution overnight at 90°C for 6 hours to evaporate excess toluene, and solidify the mixed solution to form a film on the glass negative film to prepare a PDMS film sample.

[0049] (6) The thin film sample prepared in step (5) is combined with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com