Magnetic force constraint piston type stable flow valve

A steady flow valve and piston type technology, which is applied in safety valves, balance valves, valve devices, etc., can solve the problems of high cost, high maintenance cost of single pump and double pump circuit steady flow valves, complex structure of steady flow valves, etc. To achieve the effect of simplified structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

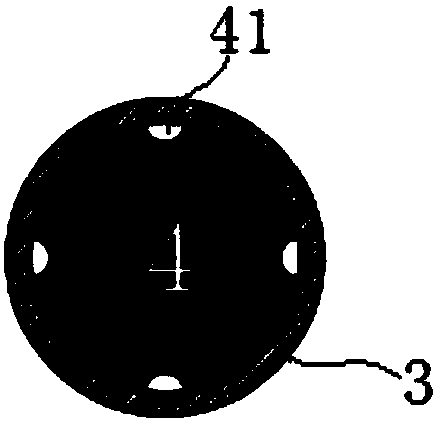

[0037] A magnetically restrained piston type steady flow valve, such as figure 1 As shown, it includes a valve body 3, a proximal gas end pipe section 1, an end cap 8, a piston 4 and a magnet 5: wherein, the proximal gas end pipe section 1 is connected to one end of the valve body 3 through a PTFE sealing plug 2; the end capping 8 It is arranged at the other end of the valve body 3, and is provided with a fluid through hole 81; the piston 4 is arranged in the valve body 3, and the end face facing the sealing end 8 is provided with a conical body 7 that matches the fluid through hole 81; and the piston 4 It has an inner iron core 6, and the magnet 5 is sleeved outside the valve body 3, and can move along the length direction of the valve body 3 (moving direction such as figure 1 shown by the double arrows).

[0038] In this embodiment, the valve body 3 is made of glass material for easy observation, the proximal gas end pipe section 1 is also made of glass material, the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com