Anti-fouling ceramic tile with sound absorption/absorption function and preparation method thereof

A ceramic brick and functional technology, applied in the field of building ceramic materials, can solve the problems of not taking into account sound absorption, adsorption and anti-fouling, difficult to remove dust, cumbersome preparation methods, etc., to achieve easy cleaning, increase adsorption capacity, and improve indoor environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

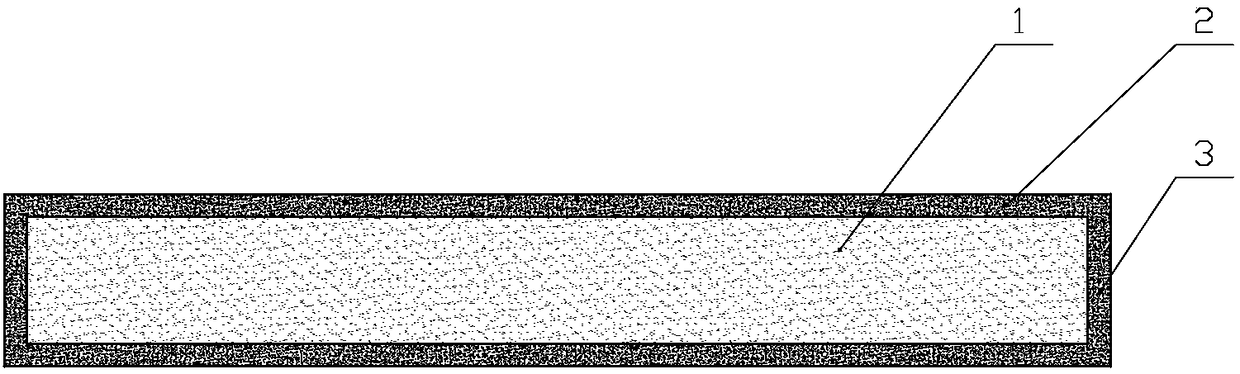

[0033] figure 1 Shown is one embodiment of the anti-fouling ceramic tile with sound absorption / adsorption function and its preparation method of the present invention.

[0034] 1. In this embodiment, an anti-fouling ceramic tile with sound absorption / adsorption function is composed of an intermediate layer 1 with a porous structure and an outer wrapping layer. The outer wrapping layer is composed of the surface layer 2 and the bearing layer 3 as a whole. . like figure 1 As shown, in this embodiment, the middle layer 1 is nested in the bearing layer 3, and the bearing layer 3 and the surface layer 2 are integrated to form an outer wrapping layer that fully wraps the middle layer.

[0035] Among them, the raw materials of the middle layer are activated carbon, diatom mud, and water; the raw materials of the outer coating layer are waste particles of building ceramic whole body bricks, waste glass powder, clay, feldspar, and water.

[0036] 2. In this embodiment, a method for ...

Embodiment 2

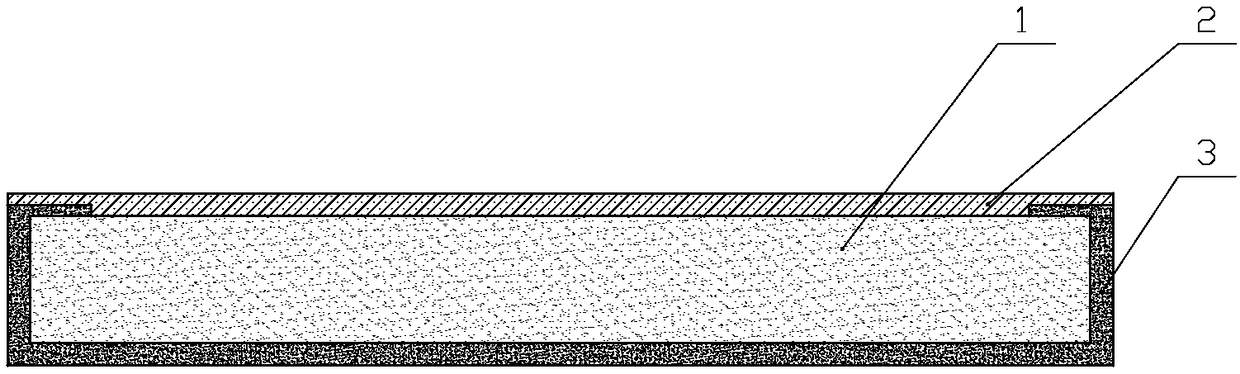

[0042] figure 2 Shown is the second embodiment of the anti-fouling ceramic tile with sound absorption / adsorption function and its preparation method of the present invention.

[0043] 1. In this embodiment, an anti-fouling ceramic tile with both sound absorption / adsorption functions is composed of an intermediate layer 1 with a porous structure and an outer wrapping layer. The outer wrapping layer is composed of a surface layer 2 and a groove-shaped bearing layer 3 Composition, wherein the surface layer 2 is a functional glaze layer. like figure 2 As shown, in this embodiment, the middle layer 1 is nested in the bearing layer 3, and the surface layer 2 as a functional glaze layer covers the surface of the middle layer 1 to wrap the middle layer.

[0044] Among them, the raw materials of the middle layer are porous ceramic (foam ceramic) waste particles, kaolin, and water; the raw materials of the bearing layer are waste particles of architectural ceramic whole body bricks,...

Embodiment 3

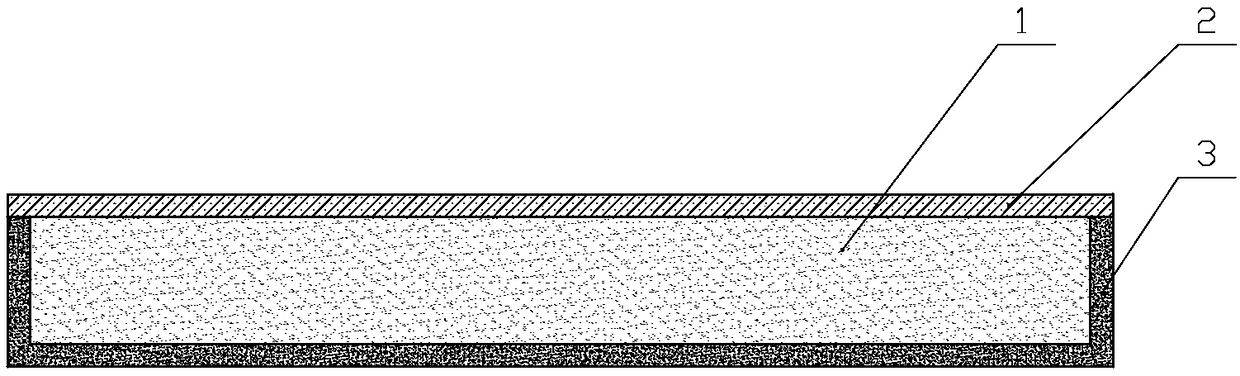

[0051] image 3 Shown is a third embodiment of an anti-fouling ceramic tile with sound absorption / adsorption function and its preparation method according to the present invention, which differs from the second embodiment in that:

[0052] (1) if image 3 As shown, the top of the bearing layer 3 of the ceramic tile in this embodiment corresponds to the edge of the upper surface of the intermediate layer 1 .

[0053] (2) In the step (1) of the preparation method, the functional glaze layer is a decorative glaze layer, and its raw materials are composed of calcium borate 50wt%, limestone 6wt%, clay 16wt%, china clay 16wt%, quartz 12wt%, according to the weight ratio of raw materials : ball mill: water=1:2:0.5, ball milled for 15 minutes, and passed through a 200-mesh sieve after ball milling to obtain the decorative glaze.

[0054] (3) In the step (2) of the preparation method, the mud material is pressed into a half-wrapped nested intermediate layer structure corresponding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com