Ultra-high molecular weight polyethylene fiber bulletproof composite material and preparation method

A bulletproof composite material and ultra-high molecular weight technology, which is applied in the field of high-strength bulletproof composite materials, can solve the problems of inability to form mechanical occlusion, difficult resin wetting, negative influence of UHMWPE fiber and resin adhesion, etc., to achieve fatigue resistance Good performance and environmental adaptability, simple steps, high specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

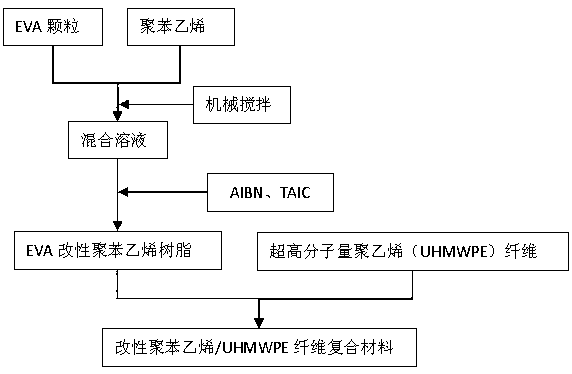

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation, but of course the following examples of implementation should not be construed as limiting the present invention.

[0024] An ultra-high molecular weight polyethylene fiber bulletproof composite material is composed of modified polystyrene resin and ultra-high molecular weight polyethylene UHMWPE fiber. The modified polystyrene resin is made of high flexibility, elasticity, and filler compatibility. The permanent ethylene-vinyl acetate copolymer EVA is made by modifying polystyrene resin; the polymer obtained by free-radical polymerization of the monomer styrene of the polystyrene resin is colorless, transparent, and has High rigidity, and can improve the wettability of the modified resin to the fiber.

[0025] Described modified polystyrene resin is made of ethylene vinyl acetate copolymer EVA, styrene ST, azobisisobutyronitrile AIBN, tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com