Biocharcoal-based slow release fertilizer and preparation method thereof

A biochar, slow-release fertilizer technology, applied in nitrogen fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of slow release, refractory polymer degradation, polluted soil, etc., to delay release and diffusion, enrich surface functional groups, improve Effects of Soil Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

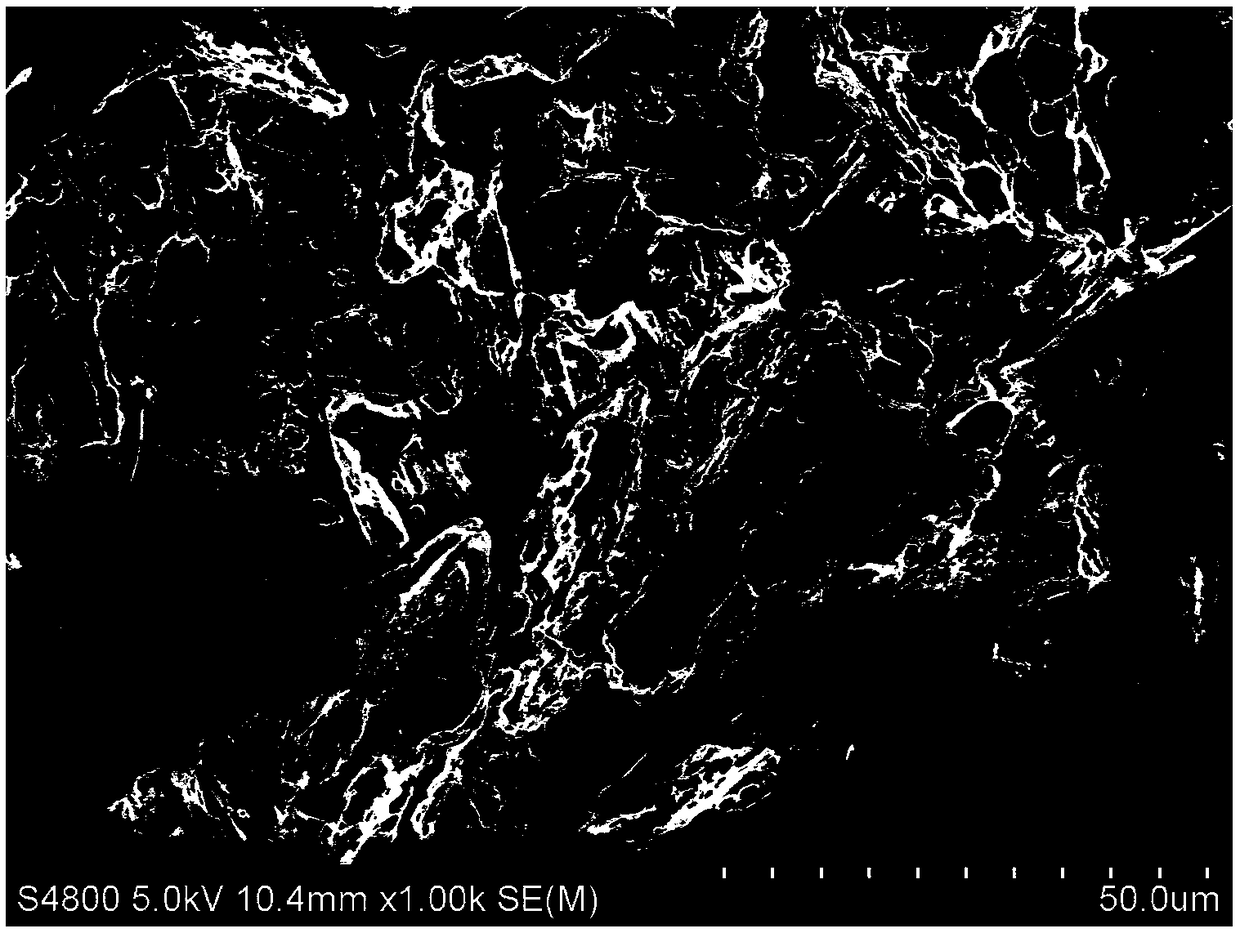

Image

Examples

Embodiment 1

[0031] A biochar-based slow-release fertilizer of the present invention, the raw materials of which include the following components: rapeseed stalks, urea and water. Its preparation method comprises the following steps:

[0032] (1) Dry the rapeseed stalks, crush them to a particle size of 100 mesh by crushing equipment, and place them in a carbonization furnace under nitrogen protection for pyrolysis and carbonization. The pyrolysis and carbonization temperature is 400°C, and the pyrolysis and carbonization time is 3 hours. , after the carbonization is completed, take it out and dry it to obtain biochar;

[0033] (2) Mix the biochar powder and urea obtained after the step (1) with 20g and 5g respectively and add into 100ml of distilled water, stir and mix evenly, place in a 300ml closed reaction kettle, heat to 135°C, and keep warm for 3h, Carry out hydrothermal reaction, cool naturally to room temperature after the reaction is completed, take out the black product in the r...

Embodiment 2

[0035] A biochar-based slow-release fertilizer of the present invention, the raw materials of which include the following components: rapeseed stalks, urea and water. Its preparation method comprises the following steps:

[0036] (1) Dry the rapeseed stalks, crush them to a particle size of 100 mesh by crushing equipment, and place them in a carbonization furnace under nitrogen protection conditions for pyrolytic carbonization. The pyrolytic carbonization temperature is 700°C, and the pyrolysis carbonization time is 3 hours. , after the carbonization is completed, take it out and dry it to obtain biochar;

[0037] (2) Mix the biochar powder and urea obtained after the step (1) with 20g and 10g respectively and add into 100ml of distilled water, stir and mix evenly, place in a 300ml airtight reaction kettle, heat to 165°C, keep warm for 3h, Carry out hydrothermal reaction, cool naturally to room temperature after the reaction is completed, take out the black product in the rea...

Embodiment 3

[0039] A biochar-based slow-release fertilizer of the present invention, the raw material includes the following components: rape straw, potassium hydroxide, urea and water. Its preparation method comprises the following steps:

[0040] (1) Dry the rapeseed stalks, crush them to a particle size of 100 mesh by crushing equipment, and place them in a carbonization furnace under nitrogen protection for pyrolysis and carbonization. The pyrolysis and carbonization temperature is 400°C, and the pyrolysis and carbonization time is 3 hours. , after the carbonization is completed, take it out and dry it to obtain biochar;

[0041] (2) Fully grind and mix 5 g of the biochar obtained after the step (1) with 10 g of potassium hydroxide, place it under nitrogen protection conditions for pyrolysis activation, the activation temperature is 700 ° C, and the activation time is 3 hours. Rinse with distilled water until neutral to obtain a black product, and dry to obtain activated biochar with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com