Wearing plate for eddy current track braking system and manufacturing method thereof

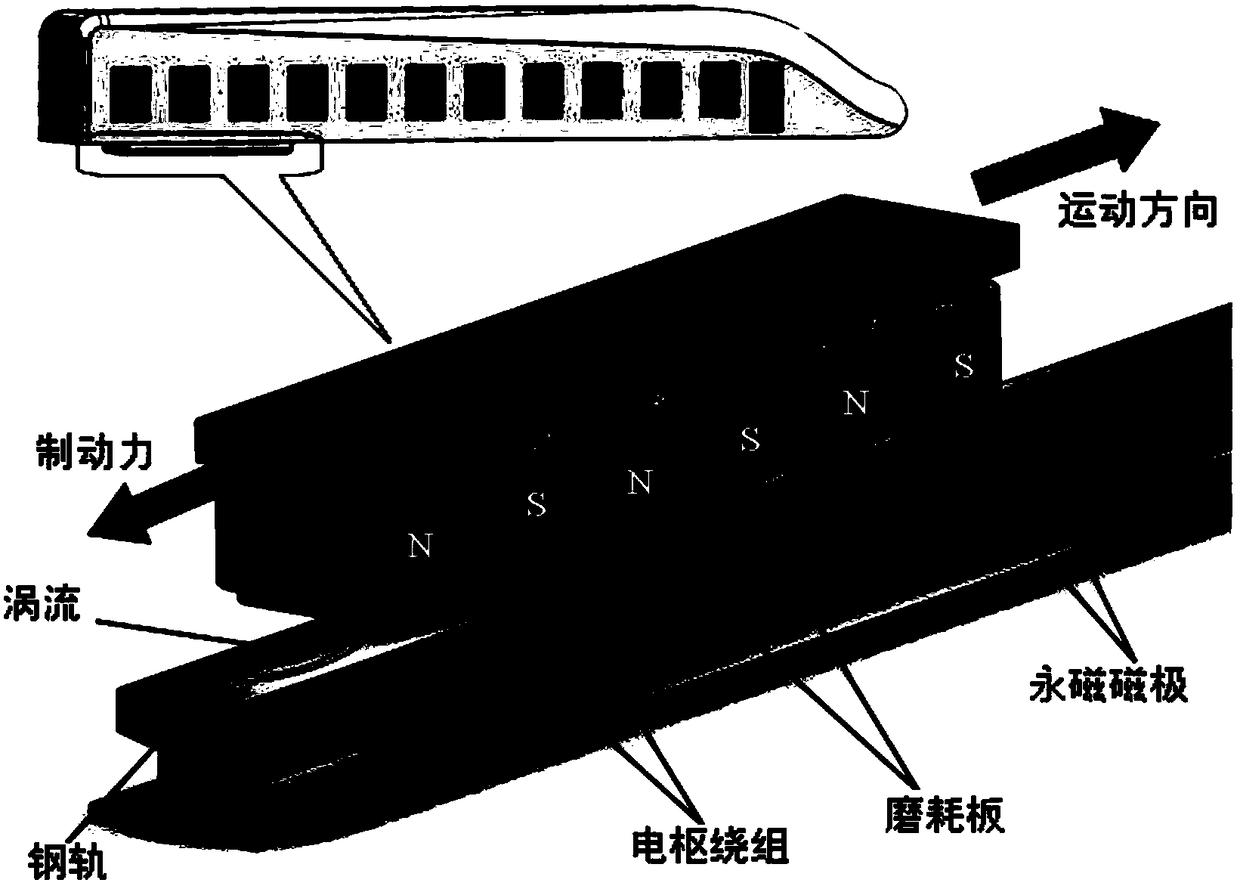

A braking system and manufacturing method technology, applied in the direction of railway braking system, braking components interacting with the track, transportation and packaging, etc., can solve the problems of braking force loss, natural eddy current braking system can not work, etc., Achieve the effect of eliminating the magnetic gap, enhancing the wear resistance and improving the permanent magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, a wear plate for an eddy current rail braking system.

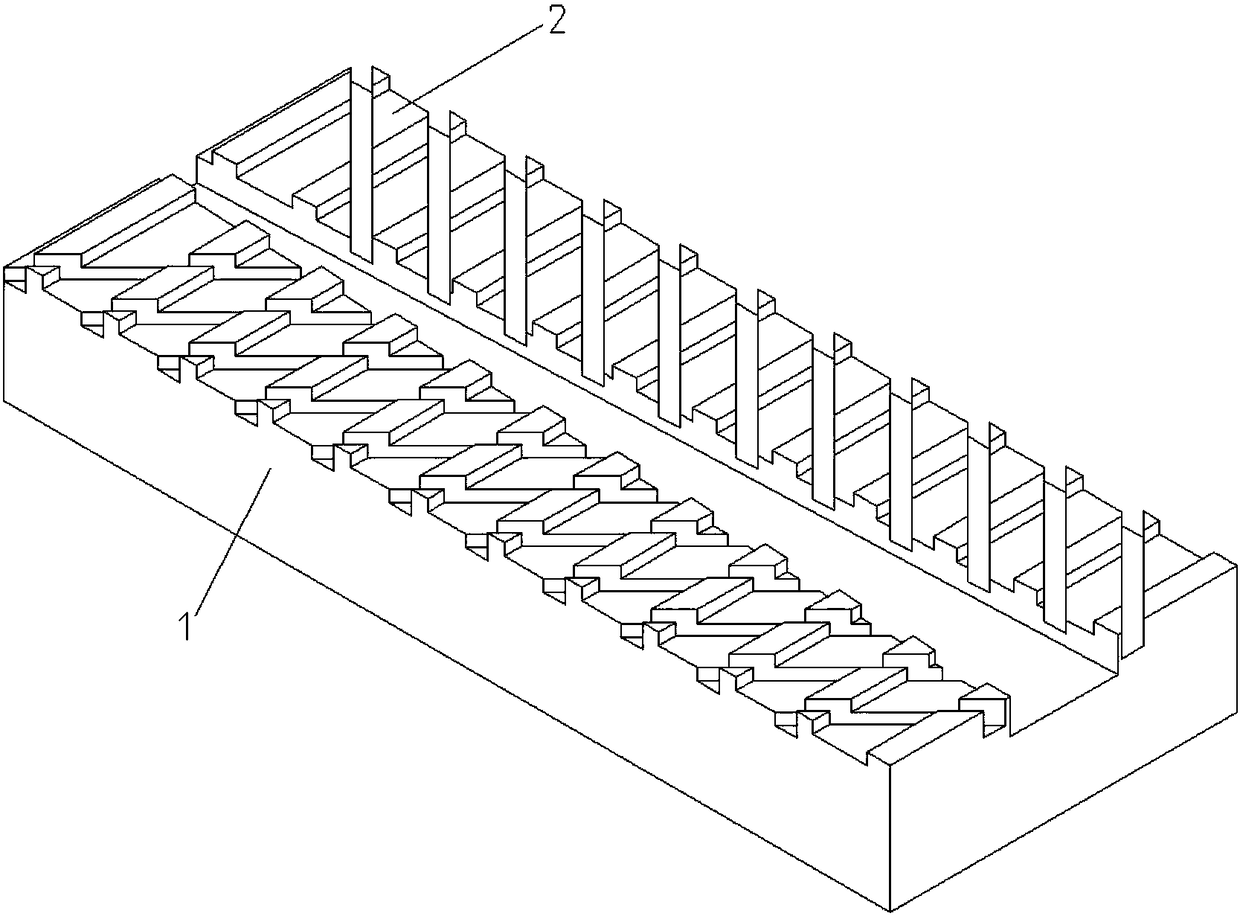

[0042] like figure 1 As shown, the wear plate provided by the present invention includes a metal base material 1 and a non-metal base material 2. Part of the surfaces of the metal base material 1 and the non-metal base material 2 are bonded together, and the bonded part of the surface is hereinafter referred to as the contact surface.

[0043] Wherein, the material of the metal substrate 1 is copper alloy, the material of the non-metal substrate 2 is a polymer material, and the volume ratio of the metal substrate 1 and the non-metal substrate 2 is 4:1-3:2.

[0044] Preferably, the volume of the metal substrate 1 accounts for 60% of the total volume, the volume of the non-metallic material accounts for 40% of the total volume, or the volume of the metal substrate 1 accounts for 80% of the total volume, and the volume of the non-metallic material accounts for 40% of the total volume. 20% of the volume....

Embodiment 2

[0055] Embodiment 2, a preparation method of a wear plate for an eddy current rail braking system.

[0056] The method of this example is used to prepare the wear plate described in Example 1.

[0057] The method specifically includes the following steps:

[0058] (1) Prefabricated metal substrate.

[0059] The metal substrate is the basic part of the wear plate. First, the material and shape of the metal substrate need to be determined, and the contact surface should be treated at the same time, so that the metal and non-metal parts can be combined. The specific steps of prefabricating the metal substrate are as follows:

[0060] (1.1) Weigh the required pure Cu block, pure Fe block, pure Ni block and pure Ag block according to the composition ratio of the metal substrate.

[0061] (1.2) Put the above-mentioned raw materials in a medium-frequency induction furnace to heat and melt, and cover the molten pool with a graphite layer for protection when melting.

[0062] (1.3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com