Edible low-calorie rare sugar sweetening agent composition

A technology of sweetener and composition, applied in the field of combination of rare sugar sweeteners, which can solve the problems of high calorie and inability to satisfy safety, taste, process, cost, bitterness or peculiar smell at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

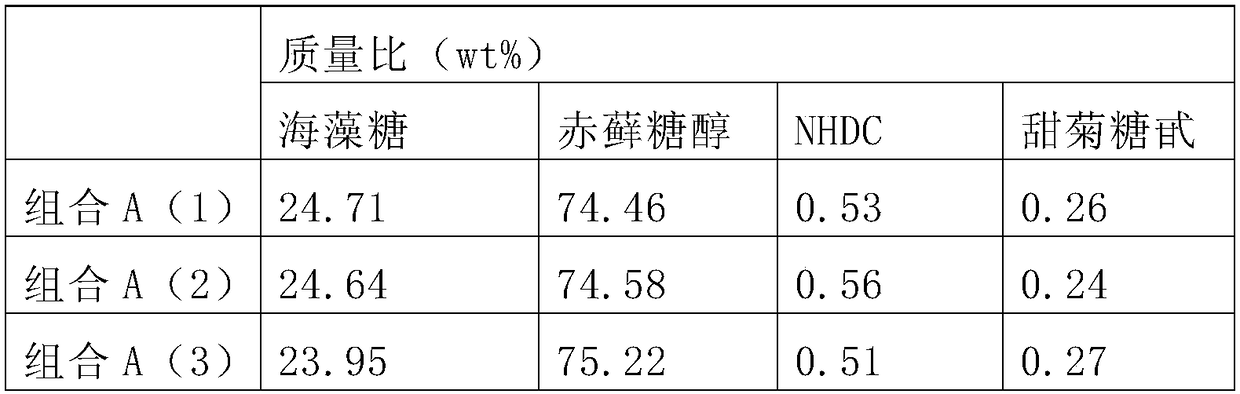

[0075] 1. Weigh 5g of sweetener mixture according to the mass ratio in Table 2

[0076] Table 2

[0077] Element

Mass ratio (wt%)

25%

74.25%

0.50%

0.25%

[0078] 2. Preparation of sweetener combination A: Dissolve the sweetener combination with 150mL of water at 40-50°C completely, then perform rotary evaporation at 50°C, concentrate until a large amount of solids are precipitated, and then transfer the solids after further rotary evaporation to remove the remaining water Put it in a vacuum drying oven until the solid is completely dry, grind the solid into a powder with a mortar, and pass through a sieve to obtain a uniform sweetener combination A of more than 80 mesh.

[0079] 3. Chromatographic analysis of the homogeneity of the sweetener combination A obtained above

[0080] Randomly weigh five portions of the above-mentioned sweetener combination A to ...

Embodiment 2

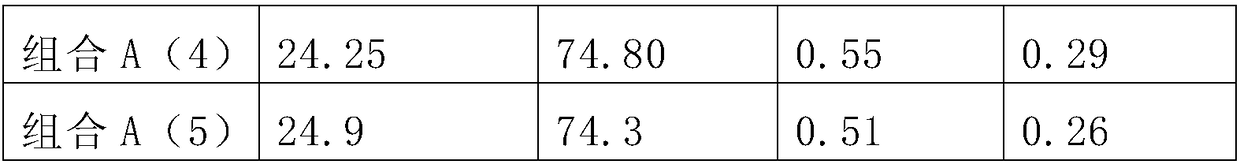

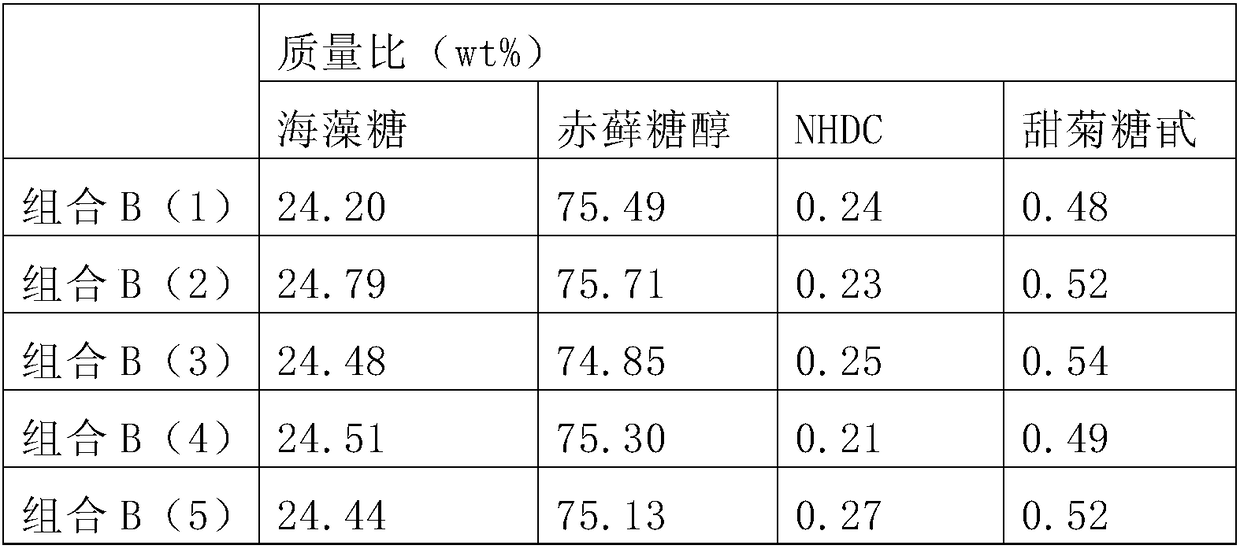

[0087] 1. Weigh 5g of the sweetener mixture according to the mass ratio shown in Table 4

[0088] Table 4

[0089] Element

Mass ratio (wt%)

25%

74.25%

0.25%

0.50%

[0090] 2. Preparation of sweetener combination B: the same as the preparation method of sweetener combination A.

[0091] 3. Chromatographic analysis of the homogeneity of the sweetener combination B obtained above

[0092] Randomly weigh five portions of the above-mentioned sweetener combination B to analyze its composition by liquid phase, and the sweetener combination obtained by this method has better uniformity. The results are shown in Table 5.

[0093] table 5

[0094]

[0095] 4. Measure the sweetness of sweetener combination B, which is about 1.75 times the sweetness of sucrose;

[0096] 5. The well-mixed sweetener combination is sealed and packaged.

[0097] It can be seen from ...

Embodiment 3

[0099] Select 10 volunteers to evaluate the mouthfeel of the sweetener composition of the present invention with a scoring system. Among them, 3-4 points are divided into mouthfeel and sucrose, which are very different from sucrose, 5-6 points are slightly close to sucrose, and 7-8 points are The taste is close to sucrose, with 9-10 points being very close to sucrose, with almost no difference. The scores shown in Table 6 are average scores calculated for the case where 10 people gave scores.

[0100] The results are shown in Table 6.

[0101] Table 6

[0102] Trehalose

7.5 points

7.7 points

4.8 points

5.6 points

The sweetener composition of embodiment 1 and embodiment 2

8.5 points

sucrose

10 points

[0103] As can be seen from Table 6, the sweetener composition of the present invention has the characteristics of mouthfeel close to sucrose, pure mouthfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com