A kind of bn/cuag/cnt composite material and its preparation method and application

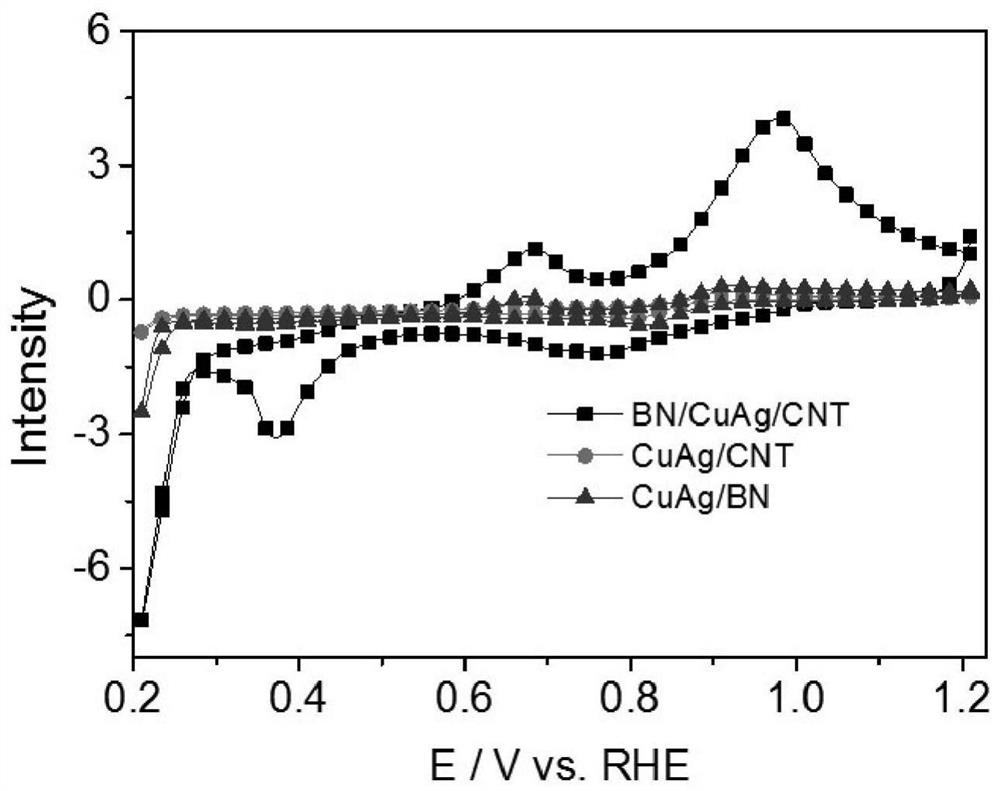

A technology of composite materials and immobilization, applied in the field of electrocatalytic materials, can solve the problems of rare electrochemical performance tests, and achieve the effects of high-efficiency electrocatalytic oxygen reduction performance, improved electrical conductivity, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

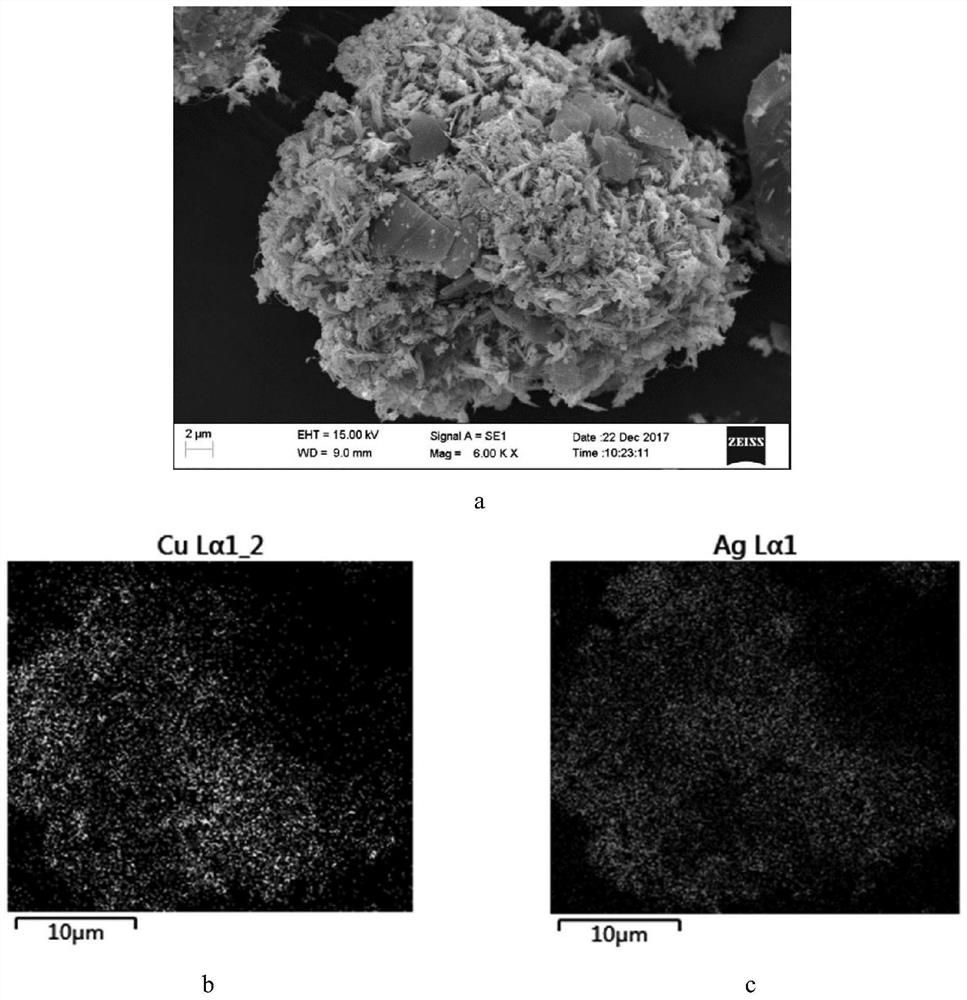

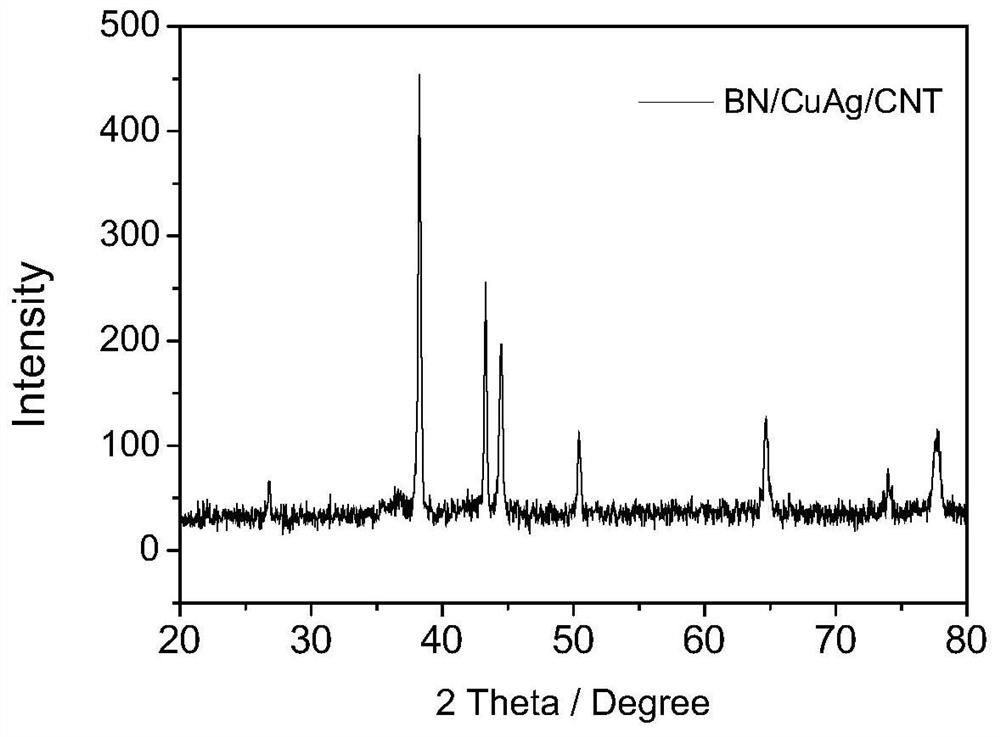

[0041] A BN / CuAg / CNT composite material. Metal CuAg particles are uniformly attached between the BN sheets and the surface of the sheets, and CNT fixes Ag, Cu and BN to form a cage structure. Among them, the molar ratio of BN, Cu, Ag and CNT is 1:1:1:1.

[0042] The preparation method includes the following steps:

[0043] (1) Add 30mL deionized water into a 100mL small beaker, and while stirring with a magnetic stirrer, add 1.2080g (0.005mol) Cu(NO 3 ) 2 ·2H 2 O, 0.8494g (0.005mol) AgNO 3 , Stir until it dissolves to obtain a light blue uniform liquid, slowly add concentrated ammonia water until precipitation is generated and then the precipitation is dissolved to obtain a mixed solution;

[0044] (2) Add 2 mL of ethylene glycol, 0.06 g (0.005 mol) of carbon nanotubes, and 0.124 g (0.005 mol) of hexagonal boron nitride to the above-mentioned mixed solution, stir for 2 minutes and then ultrasound for 30 minutes to make the mixture uniform;

[0045] (3) At room temperature, slowly add ...

Embodiment 2

[0050] The preparation method of the BN / CuAg / CNT composite material in this example is the same as that in Example 1, except that in step (3), vacuum drying is performed at 90°C for 5 hours. After grinding, under argon atmosphere, Calcination in tube furnace at 850℃ for 1.5h.

Embodiment 3

[0052] The preparation method of the BN / CuAg / CNT composite material in this example is the same as that of Example 1, but the difference is that in step (3), vacuum drying is performed at 80°C for 6 hours. After grinding, under argon atmosphere, Calcined in a tube furnace at 800℃ for 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com