Preparation process of lithium ion battery negative paste, lithium ion battery negative pole plate and lithium ion battery

A technology for lithium ion batteries and negative electrode slurry, which is applied in battery electrodes, electrode carriers/current collectors, electrode manufacturing, etc., and can solve problems such as the improvement of the dispersibility and consistency of the unfavorable slurry, the overall performance of the negative electrode, and the utilization of equipment. problems such as low rate, to achieve the effect of improving equipment utilization, shortening batching time, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

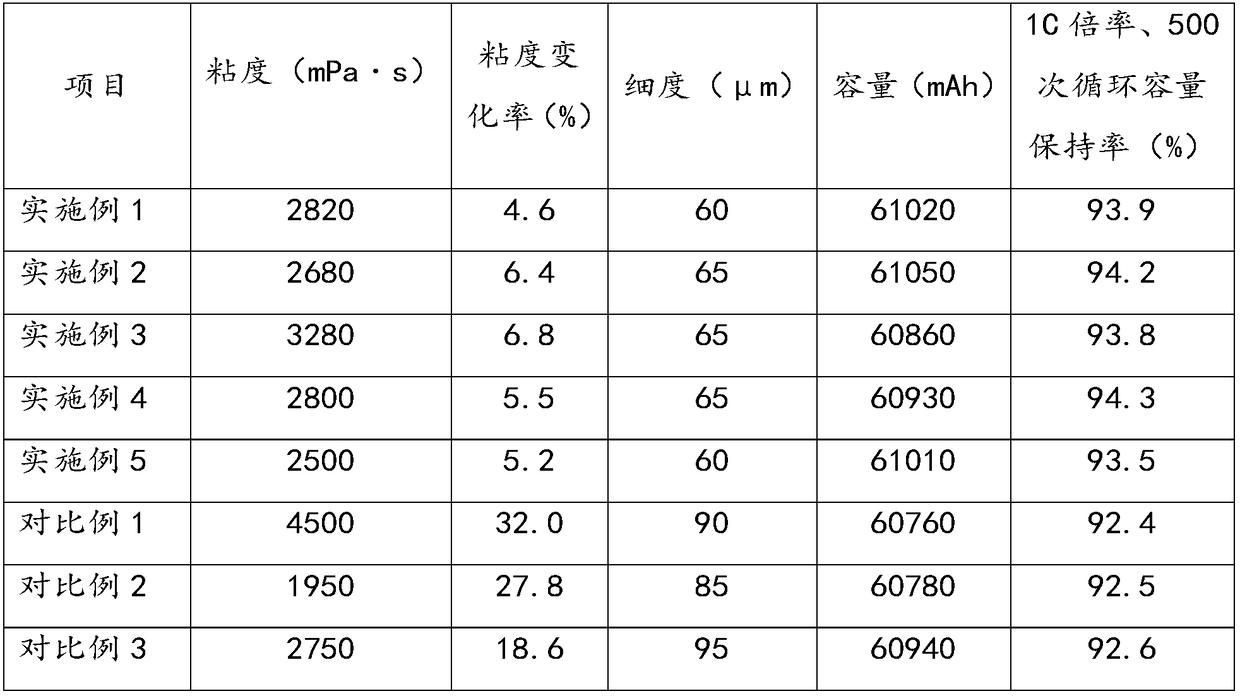

Examples

Embodiment 1

[0105] A batching process of a lithium ion battery negative electrode slurry, comprising the following steps:

[0106] (a) Calculate and weigh natural graphite, conductive carbon black, polyethylene glycol and CMC according to the mass ratio, and perform dry mixing for 30min at the speed of revolution 20r / min and rotation 0r / min to obtain mixed powder;

[0107] (b) adding deionized water, firstly mixing and stirring for 10 minutes at the speed of revolution 20r / min and rotation 0r / min, then mixing and stirring for 120min at the speed of revolution 35r / min and rotation 0r / min, to obtain a solid content of 68.2wt% For the primary slurry, the amount of deionized water added is based on a solid content of 68.2 wt%;

[0108] (c) Add deionized water, firstly mix and stir for 10min at the speed of revolution 20r / min and rotation 0r / min, and then mix and stir for 90min at the speed of revolution 35r / min and rotation 1000r / min, to obtain a solid content of 60.1wt% The secondary slurry...

Embodiment 2

[0113] A batching process of a lithium ion battery negative electrode slurry, comprising the following steps:

[0114] (a) Calculate and weigh artificial graphite, conductive carbon black, polyethylene glycol and CMC according to the mass ratio, and perform dry mixing for 35min at the speed of revolution 20r / min and rotation 0r / min to obtain mixed powder;

[0115] (b) adding deionized water, firstly mixing and stirring for 12min at the speed of revolution 20r / min and rotation 0r / min, and then mixing and stirring for 115min at the speed of revolution 35r / min and rotation 0r / min to obtain a primary solid content of 68wt% Slurry, the amount of deionized water added is 68wt% solid content;

[0116] (c) Add deionized water, mix and stir for 15 minutes at the speed of revolution 20 r / min and rotation 0 r / min, and then mix and stir for 60 min at the speed of revolution 35 r / min and rotation 1000 r / min to obtain a solid content of 60 wt% Secondary slurry, the amount of deionized wate...

Embodiment 3

[0121] A batching process of a lithium ion battery negative electrode slurry, comprising the following steps:

[0122] (a) Calculate and weigh activated carbon, conductive carbon fiber, polyvinylpyrrolidone and CMC according to the mass ratio, and perform dry mixing for 30min at the speed of revolution 25r / min and rotation 0r / min to obtain mixed powder;

[0123] (b) adding deionized water, firstly mixing and stirring for 10 minutes at the speed of revolution 15r / min and rotation 0r / min, and then mixing and stirring for 120min at the speed of revolution 45r / min and rotation 0r / min to obtain a primary solid content of 69wt% Slurry, the added amount of deionized water is based on the solid content of 69wt%;

[0124] (c) Add deionized water, firstly mix and stir for 10min at the speed of revolution 15r / min and autorotation 0r / min, then mix and stir for 90min at the speed of revolution 30r / min and autorotation 1500r / min to obtain a solid content of 61wt% Secondary slurry, the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com