Monocrystalline silicon pulling furnace, and pulling method for growing monocrystalline silicon

A technology for growing single crystal silicon and single crystal silicon, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of complex and uneconomical production process of solid silicon material, and achieve energy saving, investment saving, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

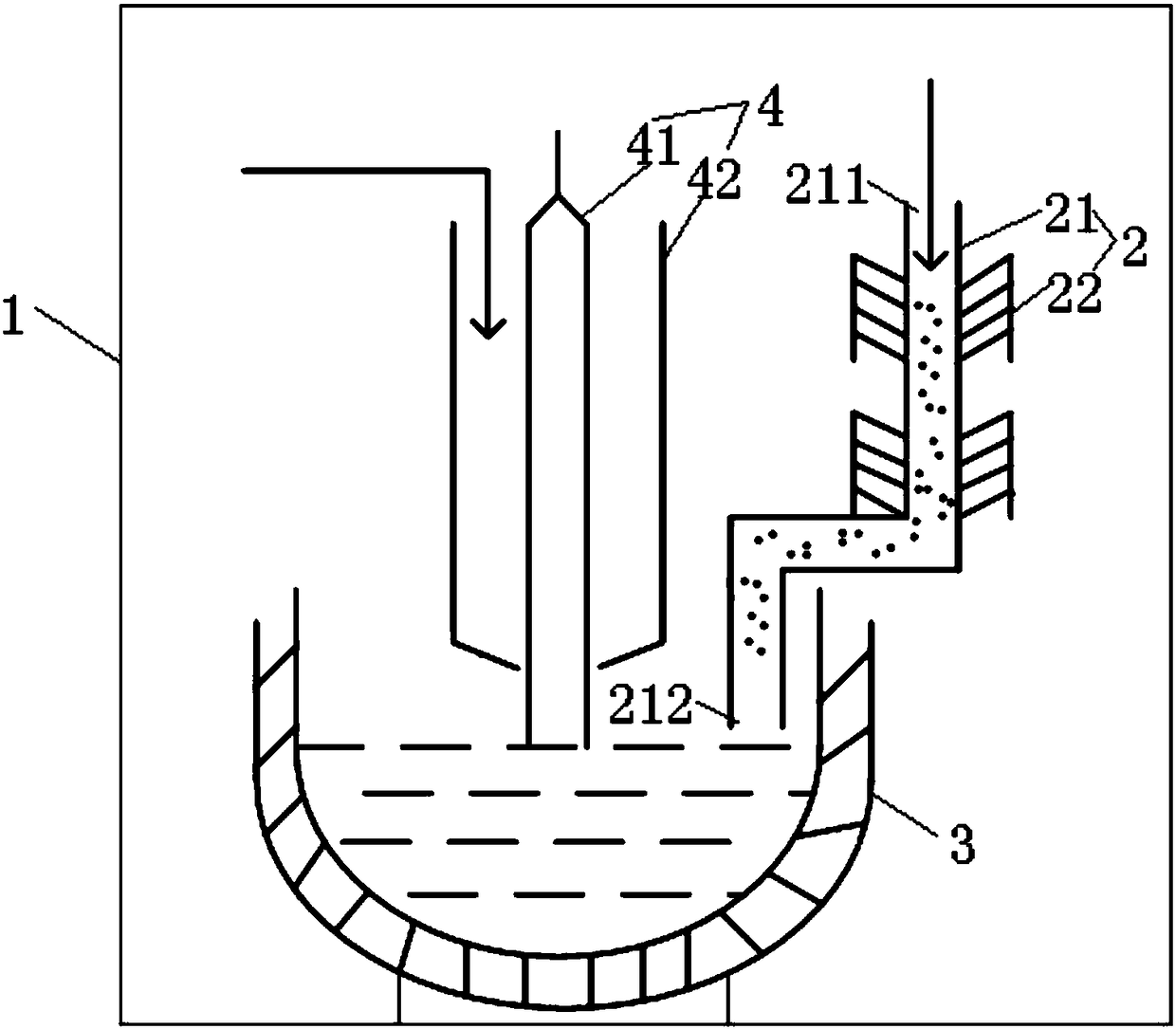

[0031] Such as figure 1 As shown, this embodiment provides a single crystal silicon pulling furnace, comprising: a furnace cavity 1, a tubular reactor 2 for heating, a crucible 3, a single crystal silicon pulling mechanism 4, and a The heater for heating the crucible 3, the gaseous silicon source thermally decomposes and reacts in the tubular reactor 2 to generate silicon powder, the silicon powder or silicon powder melts into molten silicon and enters the crucible 3, and the single crystal silicon pulling mechanism 4 is installed in the crucible Above 3, the single crystal silicon pulling mechanism 4 is used to pull the seed crystal to pull the molten silicon in the crucible 3 to grow single crystal silicon.

[0032] Specifically, the tube reactor 2 in this embodiment includes a tube body 21 and a heating element 22 for heating the tube body 21. The tube body 21 includes a tube body inlet 211 and a tube body outlet 212. The gas silicon source is provided by a tube body. The ...

Embodiment 2

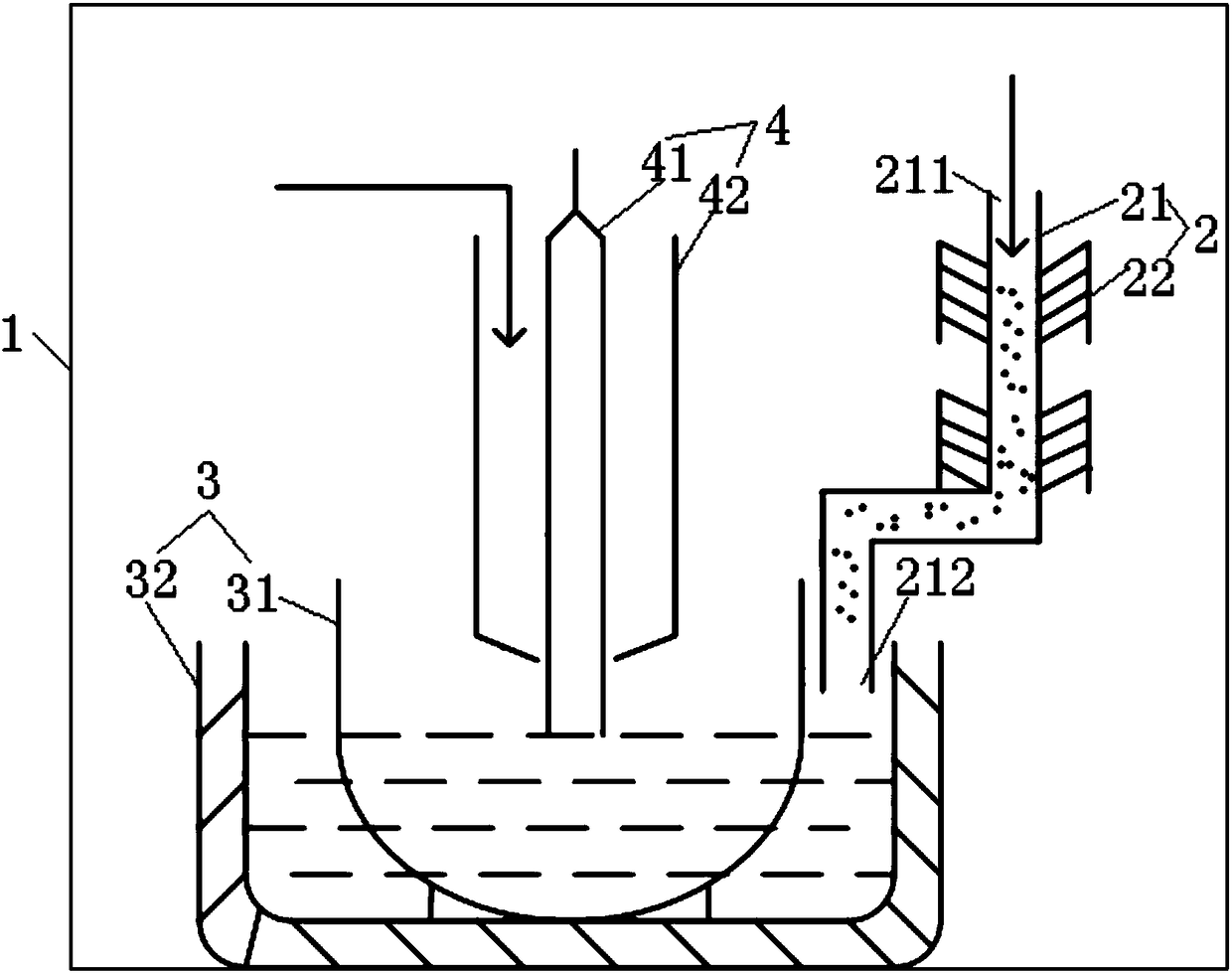

[0056] Such as figure 2 As shown, the difference between the pulling device for growing single crystal silicon in this embodiment and that in Embodiment 1 is that the crucible 3 in this embodiment includes a first sub-crucible 31 and a second sub-crucible 32, and the first sub-crucible 31 Set in the second sub-crucible 32, the openings of the first sub-crucible 31 and the second sub-crucible 32 are set in the same direction, the bottom of the first sub-crucible 31 and the second sub-crucible 32 are connected, and silicon powder or silicon powder is melted into molten silicon and enters In one of the sub-crucibles 3 , the single crystal silicon pulling mechanism 4 is used to pull the seed crystal to pull the molten silicon in the other sub-crucible 3 to grow single crystal silicon. Since the bottoms of the first sub-crucible 31 and the second sub-crucible 32 are connected, the molten silicon in the first sub-crucible 31 and the second sub-crucible 32 can communicate with each ...

Embodiment 3

[0071] This embodiment also provides a pulling method for growing single crystal silicon using the pulling device for growing single crystal silicon in embodiment 1. The difference between the method in this embodiment and the method in embodiment 1 is that:

[0072] The gaseous silicon source in this embodiment is trichlorosilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com