A kind of low-dimensional sio2 high-strength light-weight thermal insulation material and preparation method thereof

A thermal insulation material and high-strength technology, applied in the field of refractory materials, can solve the problems of complex preparation process, low service temperature, high thermal conductivity, etc., and achieve the effect of solving low strength, reducing molding pressure and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

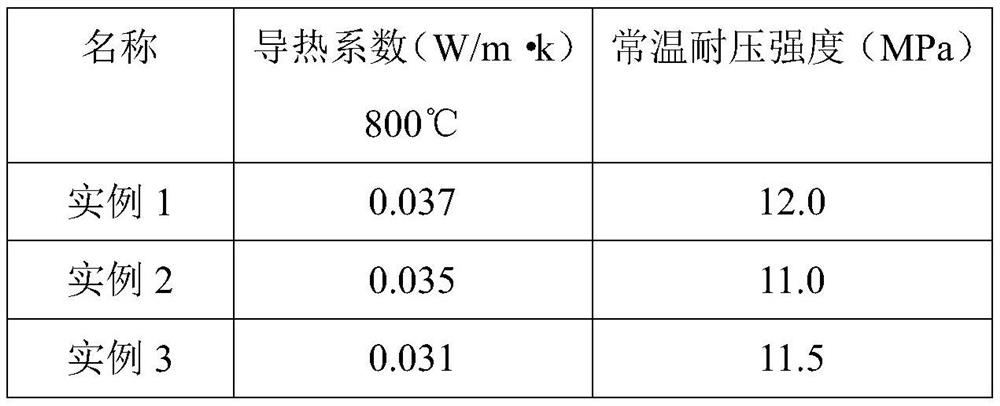

Embodiment 1

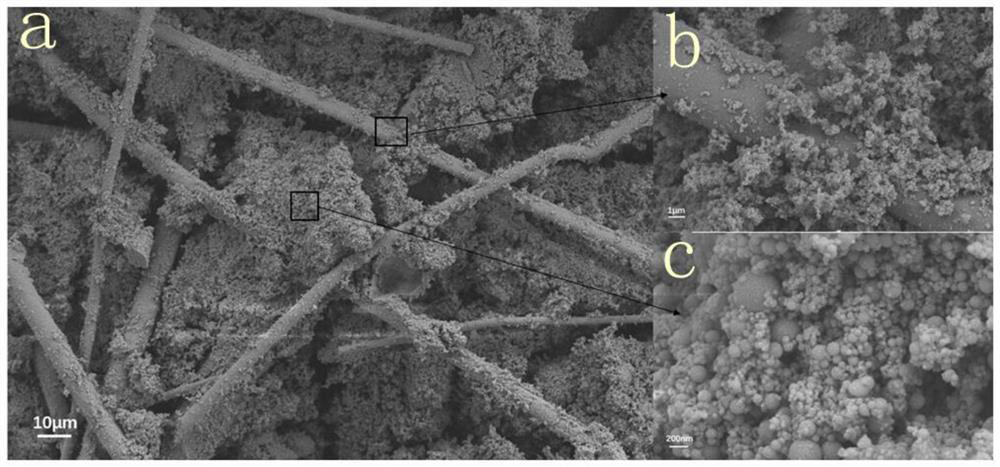

[0031] A low-dimensional SiO 2 High-strength lightweight insulation material, the low-dimensional SiO 2 High-strength and lightweight insulation materials are prepared from the following raw materials in weight percentage:

[0032] Silica powder with a particle size of 300-500nm: 55%

[0033] Silica powder with a particle size of 100-200nm: 30%

[0034] CaO-MgO-SiO 2 Quality refractory fiber: 15%;

[0035] Wherein, the silica fine powder with a particle size of 300-500nm and the silica fine powder with a particle size of 100-200nm both contain the following components: SiO 2 ≥98.5%, C≤0.8%, Al 2 o 3 ≤0.13%, MgO≤0.16%, CaO≤0.07%, Fe 2 o 3 ≤0.01%, K 2 O≤0.33%; and all are amorphous spherical;

[0036] Among them, the CaO-MgO-SiO 2 The length of high-quality refractory fiber is 3-5mm; the mass percentage of CaO is 30.0%, the mass percentage of MgO is 5.0%, and the mass percentage of SiO 2 The mass percentage content is 65.0%.

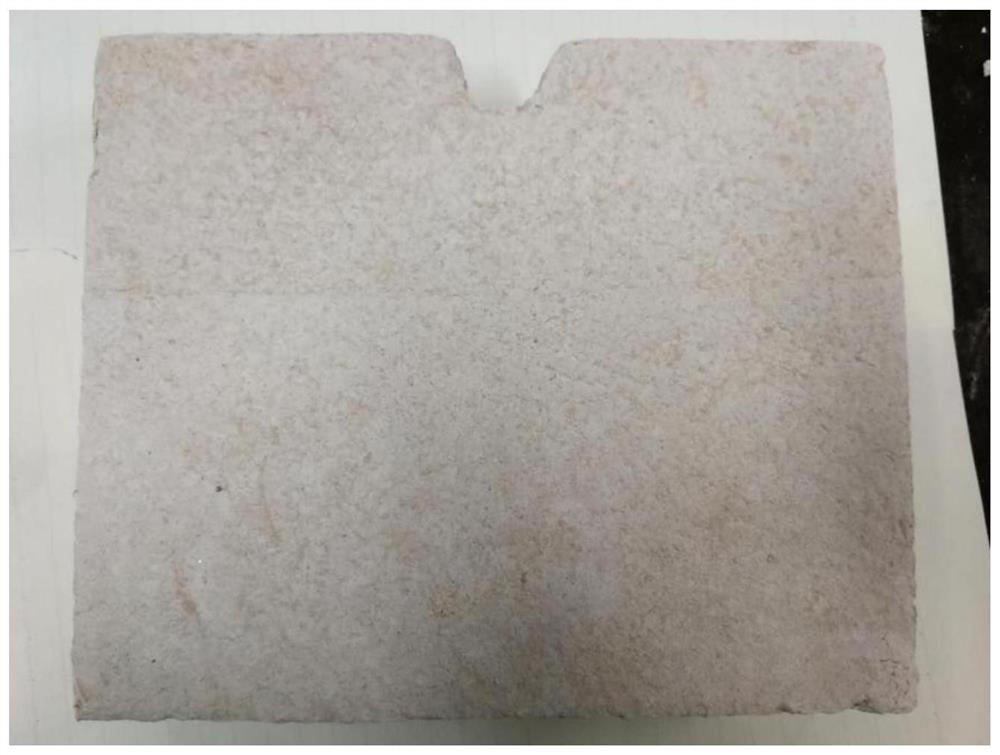

[0037] The aforementioned low-dimension...

Embodiment 2

[0043] A low-dimensional SiO 2 High-strength lightweight insulation material, the low-dimensional SiO 2 High-strength and lightweight insulation materials are prepared from the following raw materials in weight percentage:

[0044] Silica powder with a particle size of 300-500nm: 45%

[0045] Silica powder with a particle size of 100-200nm: 30%

[0046] CaO-MgO-SiO 2 Quality refractory fiber: 25%;

[0047] Wherein, the silicon dioxide fine powder with a particle size of 300-500 nm, that is, the silicon dioxide fine powder with a particle size of 100-200 nm, all contains the following components: SiO 2 ≥98.5%, C≤0.8%, Al 2 o 3 ≤0.13%, MgO≤0.16%, CaO≤0.07%, Fe 2 o 3 ≤0.01%, K 2 O≤0.33%; and all are amorphous spherical;

[0048] Among them, the CaO-MgO-SiO 2 The length of high-quality refractory fiber is 3-5mm; the content of CaO is 35.0%, the content of MgO is 8.0%, and the content of SiO 2 The content is 57.0%.

[0049] Above-mentioned low-dimensional SiO2 The prep...

Embodiment 3

[0055] A low-dimensional SiO 2 High-strength lightweight insulation material, the low-dimensional SiO 2 High-strength and lightweight insulation materials are prepared from the following raw materials in weight percentage:

[0056] Silica powder with a particle size of 300-500nm: 40%

[0057] Silica powder with a particle size of 100-200nm: 40%

[0058] CaO-MgO-SiO 2 Quality refractory fiber: 20%;

[0059] Wherein, the silicon dioxide fine powder with a particle size of 300-500 nm, that is, the silicon dioxide fine powder with a particle size of 100-200 nm, all contains the following components: SiO 2 ≥98.5%, C≤0.8%, Al 2 o 3 ≤0.13%, MgO≤0.16%, CaO≤0.07%, Fe 2 o 3 ≤0.01%, K 2 O≤0.33%; and all are amorphous spherical;

[0060] Among them, the CaO-MgO-SiO 2 The length of high-quality refractory fiber is 3-5mm; the content of CaO is 33.0%, the content of MgO is 7.0%, and the content of SiO 2 The content is 60.0%.

[0061] The aforementioned low-dimensional SiO 2 A m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com