Cold-paving cutback asphalt material modified with cement and nano-clay

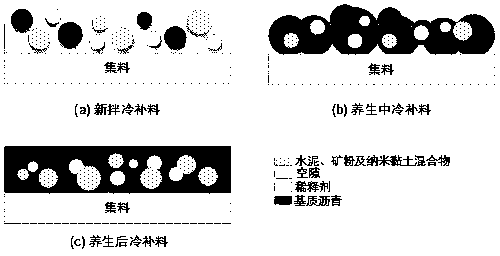

A technology of nano-clay and diluted asphalt, which is applied in the field of asphalt pavement maintenance, can solve the problems of low early strength and poor water stability, and achieve the effect of improving early strength, improving adhesion and improving water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

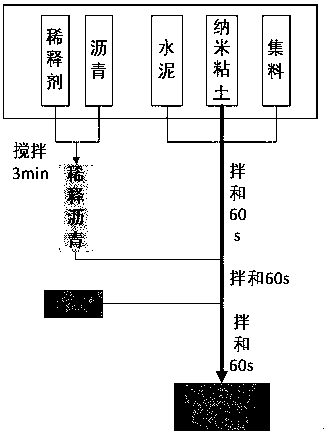

[0039] The preparation method of the diluted asphalt cold patch material modified by cement and nano-clay in the present embodiment is as follows:

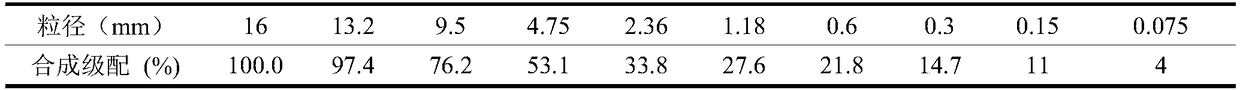

[0040] (1) Configure mineral materials according to the gradation composition, put them into a 120°C constant temperature drying oven for 4 hours; take the aggregate with a weight percentage of 92.04%, and pour it into a mixing pot, and the temperature of the stirring pot is also controlled at 120°C;

[0041] (2) Take cement and nanoclay whose weight percents are respectively 5.60% and 2.5%, mix well, pour into a mixing pot, and mix for 60 seconds;

[0042] (3) Configuration of dilute asphalt: heat and melt 70# matrix asphalt, and control the temperature at about 120°C; take 4.42% by weight of asphalt, add 1.10% by weight of diesel oil, and stir well to obtain Thin asphalt. Pour into the mixing pot and stir for 60s;

[0043] (4) Add the mineral powder component in the mineral material and stir for 60s.

Embodiment 2

[0045] The preparation method of the diluted asphalt cold patch material modified by cement and nano-clay in the present embodiment is as follows:

[0046] (1) Configure mineral materials according to the gradation composition, put them into a 120°C constant temperature drying oven for 4 hours; take the aggregate with a weight percentage of 89.76%, and pour it into a mixing pot, and the temperature of the stirring pot is also controlled at 120°C;

[0047] (2) Take cement and nanoclay whose weight percentages are respectively 6.20% and 2.9%, mix evenly, pour into a mixing pot, and mix for 60 seconds;

[0048] (3) Configuration of dilute asphalt: heat and melt 70# base asphalt, and control the temperature at about 120°C; take 4.30% by weight of asphalt, add 1.08% by weight of diesel oil, and stir well to obtain Thin asphalt. Pour into the mixing pot and stir for 60s;

[0049] (4) Add the mineral powder component in the mineral material and stir for 60s.

Embodiment 3

[0051] The preparation method of the diluted asphalt cold patch material modified by cement and nano-clay in the present embodiment is as follows:

[0052] (1) Configure mineral materials according to the gradation composition, put them into a 120°C constant temperature drying oven for 4 hours; take the aggregate with a weight percentage of 87.79%, and pour it into a mixing pot, and the temperature of the stirring pot is also controlled at 120°C;

[0053] (2) Take cement and nanoclay whose weight percentages are respectively 9.80% and 3.2%, mix evenly, pour into a mixing pot, and mix for 60 seconds;

[0054] (3) Configuration of diluted asphalt: heat and melt 70# base asphalt, and control the temperature at about 120°C; take 4.21% by weight of asphalt, add 1.05% by weight of diesel oil, and stir well to obtain Thin asphalt. Pour into the mixing pot and stir for 60s;

[0055] (4) Add the mineral powder component in the mineral material and stir for 60s.

[0056] In order to ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com