Composite polarizing plate and image display device including the same

A technology of polarizing plates and polarizers, applied in optics, polarizing elements, optical elements, etc., can solve the problems of phase difference layer peeling, failure to propose, and expansion of the adhesive layer, so as to reduce the defect rate, improve the bonding properties, The effect of excellent light leakage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0083] A polyvinyl alcohol film (PS7500, Kuraray Co.) having a thickness of 75 μm, an average degree of polymerization of 2,400, and a degree of saponification of 99.9% or more was immersed in water (deionized water) at 30° C. for 2 minutes to swell . Thereafter, the film was dipped in a staining solution containing 3.5 mmol / L of iodine and 2% by weight of potassium iodide at 30° C. for 4 minutes to be stained. Then, the treated membrane was further immersed in a cross-linking solution containing 2% by weight of potassium iodide, 3.7% by weight of boric acid, and lithium chloride at a molar ratio of 4.5 to 1 mole of potassium iodide at 50° C. for 2 minutes to make it crosslinked. couplet. During each swelling / dyeing / crosslinking / washing process, the polyvinyl alcohol film was stretched to a cumulative stretching ratio of 5.5 times to prepare a polarizer.

preparation example 2

[0085] Noblen FLX80E4 resin (Sumitomo Chemical Co., Ltd.) was placed on both sides of the resin layer (Sumitomo Chemical Co.) of Noblen W151, and a multilayer extrusion molding machine was used for co-extrusion to prepare a three-layer The substrate film of the structure, and then, polyvinyl alcohol powder Z-200 (Japan Synthetic Chemical Co., Ltd.) was heated at 90° C. to prepare a 3% by weight aqueous solution. Afterwards, Sumirejin 650 (Taoka Chemical Co., Ltd.) as a crosslinking agent was mixed in a ratio of 1% by weight to 2% by weight of polyvinyl alcohol powder to obtain a base coat layer. Coating liquid, and polyvinyl alcohol powder PVA 124 (Kuraray Co., Ltd.) was heated at 90°C to obtain an 8% by weight aqueous solution, thus preparing a polyvinyl alcohol resin-forming coating liquid. Next, the above-mentioned multilayer substrate film was subjected to corona treatment, and a primer layer was applied to the corona-treated surface using a microgravure coater, and dried ...

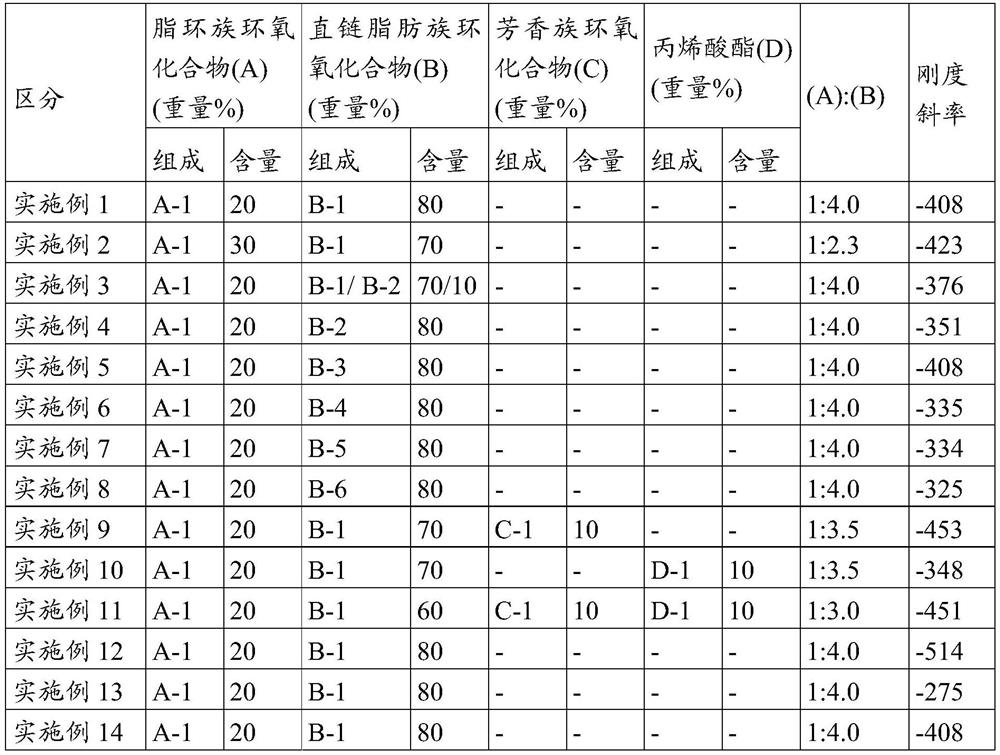

Embodiment 1

[0088] (A) Preparation of photocurable adhesive composition

[0089] By mixing 20% by weight of CEL 2021P (Daicel Company) as an alicyclic epoxy compound, 80% by weight of neopentyl glycol diglycidyl ether (Aldrich Company) as a linear aliphatic epoxy compound, 4% by weight CPI-110A (San-Apro Company) as a cationic photoinitiator to prepare an adhesive composition. In this case, the weight ratio of the cycloaliphatic epoxy compound to the linear aliphatic epoxy compound is 1:4.

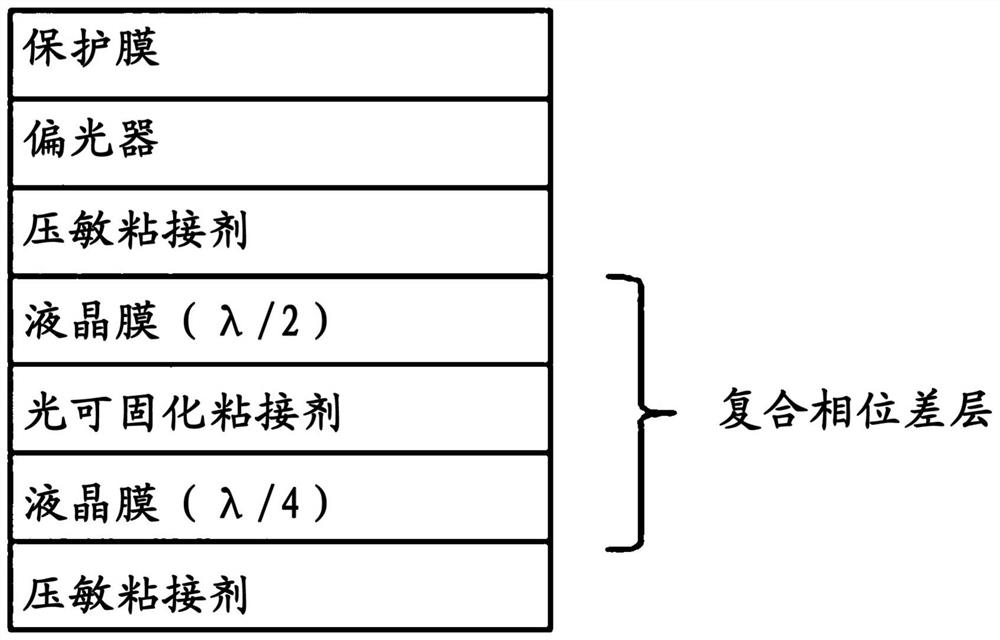

[0090] (B) Preparation of composite retardation layer

[0091] The prepared photocurable adhesive composition was bonded between the λ / 2 retardation layer and the λ / 4 retardation layer so as to form a thickness of 3 μm, and a high-pressure mercury lamp (UVA, cumulative light intensity 500 mJ / cm 2 ) for UV curing to prepare a composite retardation layer.

[0092] (C) Preparation of polarizing plate

[0093] A triacetyl cellulose film (Fuji Corporation) was bonded to one side of the polarizer prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com