Negative electrode material of zinc-based secondary batteries and preparation method thereof

A secondary battery and negative electrode material technology, applied in battery electrodes, alkaline storage batteries, circuits, etc., can solve the problems of ineffective inhibition of Zn, etc., and achieve the effects of improving hydrogen evolution overpotential and Coulombic efficiency, inhibiting deformation, and uniform metal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

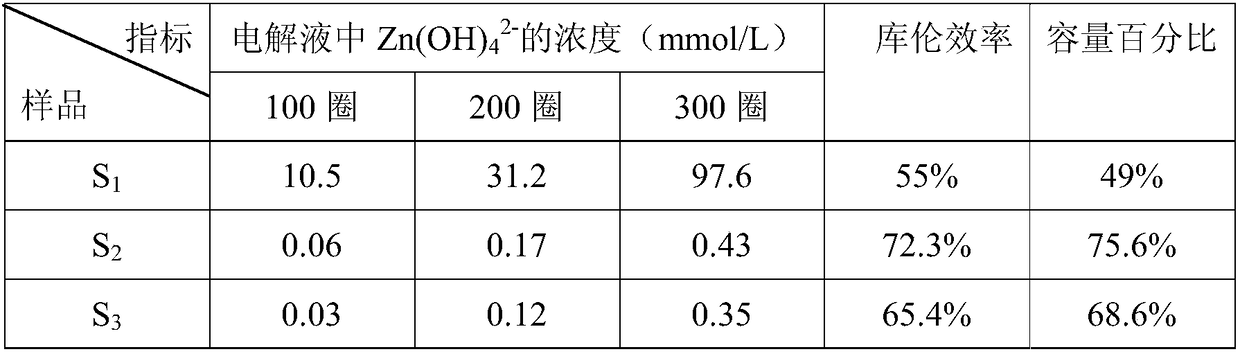

Examples

Embodiment 1

[0044] (1) Weigh 5g of zinc oxide powder in proportion and add it to 50ml of deionized water, stir for 10 minutes to form a suspension solution of zinc oxide, and then sonicate for 40 minutes to form a zinc oxide dispersion. Add 5ml of ammonia water with a mass fraction of 3% to the dispersion dropwise and stir for 5 minutes, add sodium carbonate-sodium bicarbonate buffer solution to adjust the pH of the solution to 8.5, continue stirring for 120 minutes, and then filter to obtain modified zinc oxide powder.

[0045] (2) Add the modified zinc oxide powder to 30ml of a mixed solution containing 7wt% perfluorosulfonic acid resin and 1wt% fluorine-containing acrylic resin, keep the temperature of the mixed solution at 50°C and ultrasonically 100min, then filter through Separated to obtain cationic resin-coated zinc oxide powder.

[0046] (3) Measure 50ml of SnCl with a concentration of 0.4mol / L 2 and LaCl at a concentration of 0.1mol / L 3 Put the methanol mixed solution into a b...

Embodiment 2

[0050] (1) Weigh 5 g of zinc oxide powder in proportion and add it to 60 ml of methanol, stir for 15 min to form a suspension solution of zinc oxide, and then ultrasonicate for 60 min to form a zinc oxide dispersion. Add 3ml of 5% ammonium chloride solution dropwise to the dispersion and stir for 5 minutes, add ammonia water-ammonium chloride buffer to adjust the pH of the solution to 9.4, continue stirring for 150 minutes, and then filter to obtain modified zinc oxide powder.

[0051] (2) Add the modified zinc oxide powder to 35ml of a mixed solution containing 10wt% perfluorosulfonic acid resin and 1.5wt% fluorine-containing polyurethane resin, keep the temperature of the mixed solution at 60°C and ultrasonically 150min, and then pass Filtration and separation to obtain cationic resin-coated zinc oxide powder.

[0052] (3) Measure 40ml concentration of 0.3mol / LBi(NO 3 ) 3 and 0.1mol / LCe(NO 3 ) 3 Put the mixed solution of ethylene glycol into a beaker, then add zinc oxid...

Embodiment 3

[0056] (1) The zinc oxide powder that takes 5g is added in the ethanol of 70ml, stirs 20min to form the suspension solution of zinc oxide, then ultrasonic 90min forms zinc oxide dispersion liquid, adds 6ml mass fraction to this dispersion liquid dropwise and is 5% ammonium carbonate The solution was stirred continuously, borax-sodium carbonate buffer solution was added to adjust the pH value of the solution to 10, the stirring was continued for 200 min, and then modified zinc oxide powder was obtained by filtration.

[0057] (2) Add the modified zinc oxide powder to 30ml of a mixed solution containing 15wt% perfluorosulfonic acid resin and 2wt% polystyrene-divinylbenzenesulfonic acid resin, keep the temperature of the mixed solution at 80°C and Ultrasound for 100 min, and then separated by filtration to obtain cationic resin-coated zinc oxide powder.

[0058] (3) Measure 50ml concentration of 0.6mol / LIn(NO 3 ) 3 and a concentration of 0.2mol / L Pr(NO 3 ) 3 Put the aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com