Design and manufacturing method ofsoft steel material with damping anti-seismic device for bridge

A manufacturing method and technology for bridges, applied in the field of design and manufacture of damping and anti-seismic mild steel materials for bridges, can solve problems such as high repair or reconstruction costs, increased construction costs, and lack of self-adjusting ability of the main body of the structure, etc. Excellent damping ratio and low cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

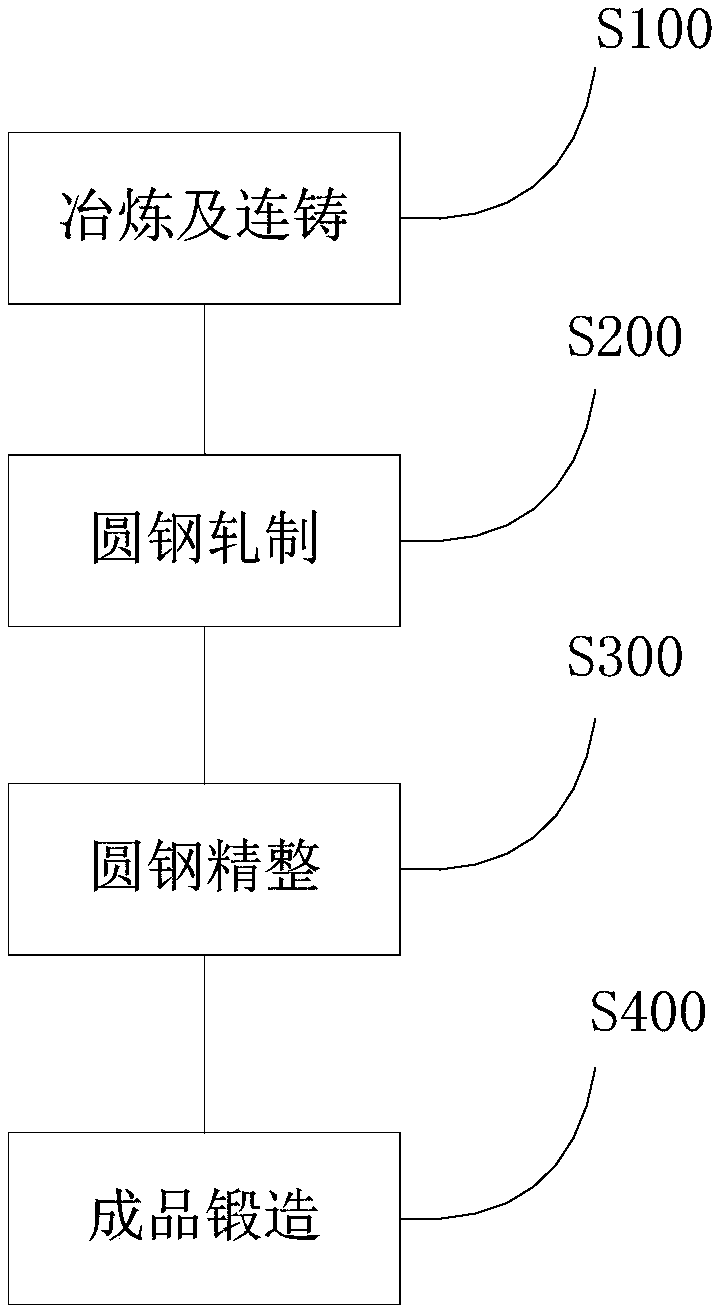

Method used

Image

Examples

Embodiment Construction

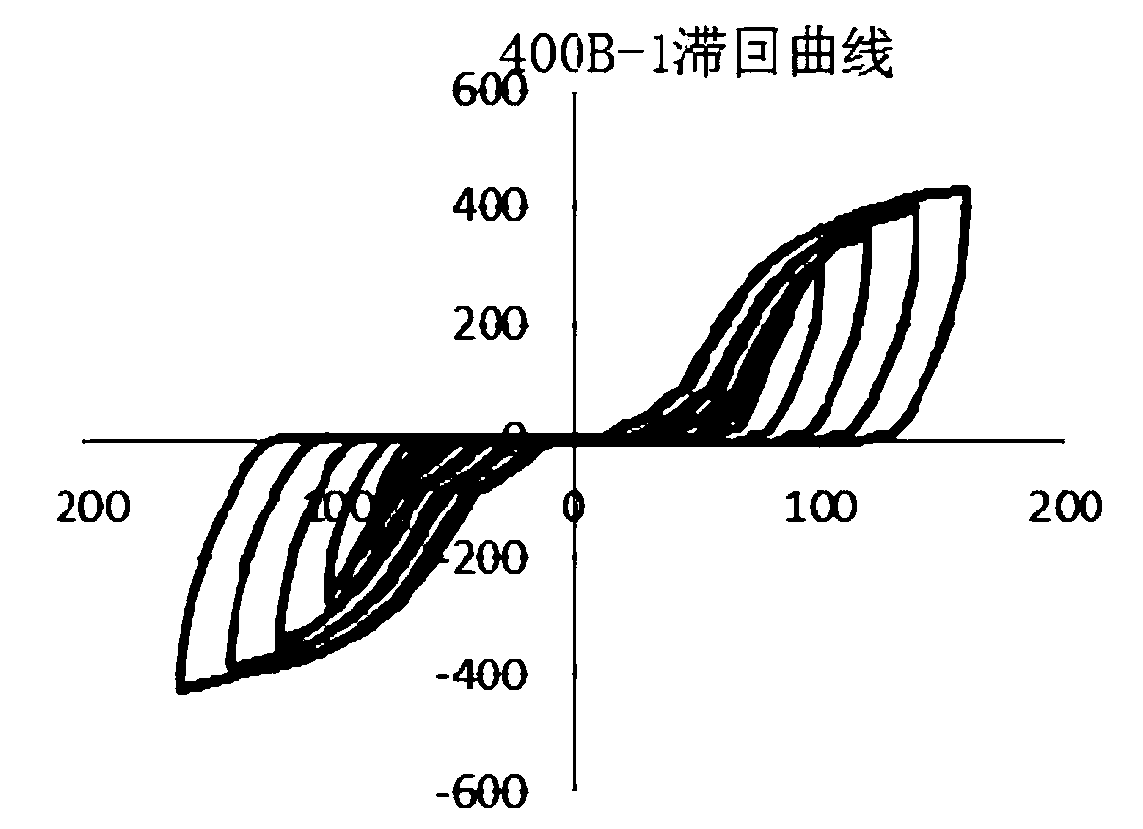

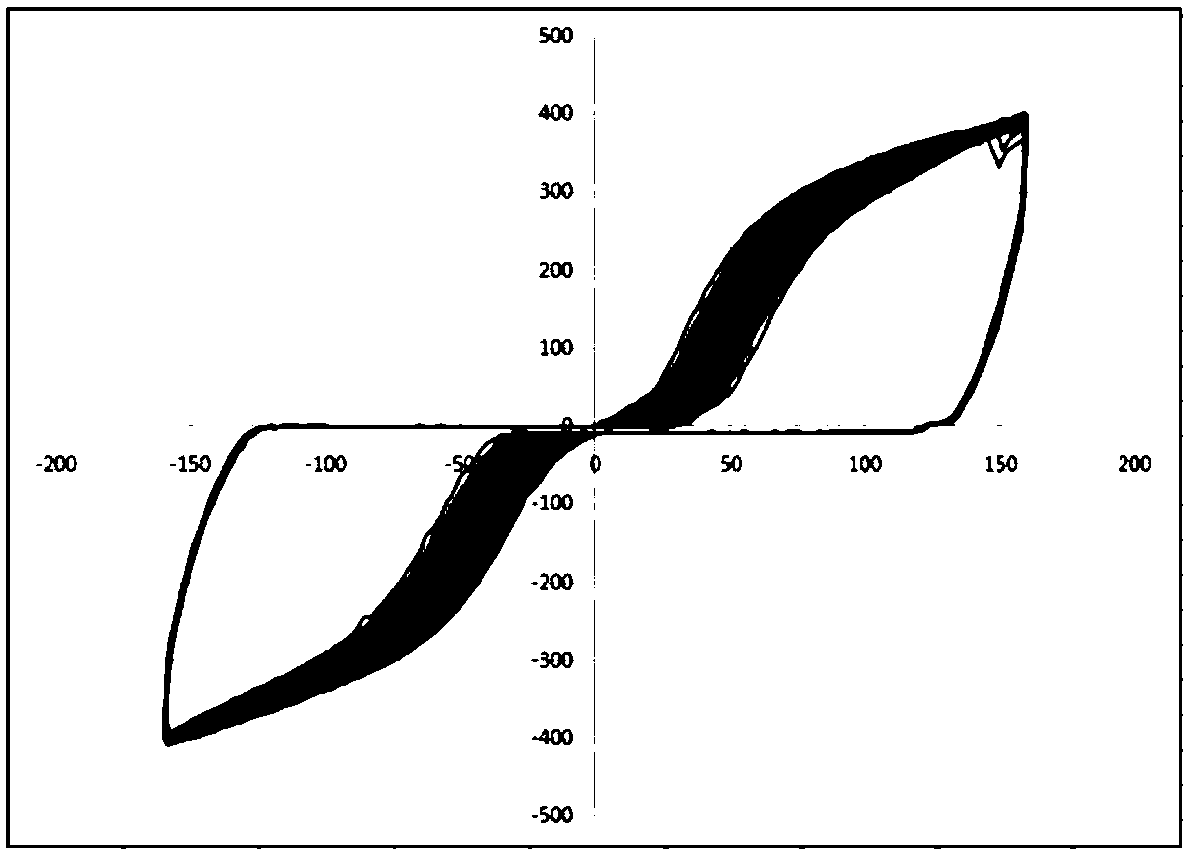

[0065] The inventors have found that different engineering application conditions have completely different mechanical performance requirements for mild steel materials used for seismic damping, and composition design is a prerequisite for ensuring mechanical performance. The stress conditions of high-speed railway bridges are more complicated. On the one hand, because the railway lines pass through mountains and ridges, the geographical conditions are complex, they are more susceptible to earthquakes, and the requirements for seismic performance are higher; on the other hand, under normal locomotive traffic conditions, not only The force is large, and the pier structure is also required to be stable and the vibration should be minimized. In addition, because the railway line spans a wide area and the temperature changes greatly, it also puts forward higher requirements on the low temperature impact performance of mild steel materials.

[0066] Based on the above purpose, base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com