Fermentation technology of L-tryptophan

A fermentation process and tryptophan technology, applied in the field of L-tryptophan fermentation process, can solve the problems of difficult control of parameters, complicated culture process, etc., and achieve the improvement of acid production efficiency, less residual sugar, and reduced feedback inhibition regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A fermentation process for L-tryptophan, comprising the steps of:

[0030] Escherichia coli CCTCC M 2011316 was cultured to a concentration of 1 × 10 7 cfu / mL seed solution, and then inoculate the fermentation medium (glucose 20g / L, corn steep liquor 10g / L, ammonium sulfate 5g / L, dipotassium hydrogen phosphate 2g / L, phosphoric acid Potassium dihydrogen 2g / L, magnesium sulfate 1.5g / L, citric acid 1.5g / L, ferrous sulfate 70mg / L, sodium sulfate 20mg / L, manganese sulfate 7mg / L, zinc sulfate 7mg / L, cobalt chloride 6mg / L, copper sulfate 0.9mg / L), the fermentation temperature is controlled at 36°C, the dissolved oxygen is controlled at 20%, the tank pressure is 0.05MPa, and the residual sugar is controlled at not less than 1.0 by adding a glucose solution with a concentration of 100g / L. %, the pH is controlled at 6.8 by feeding ammonia water; fermentation is stopped at 30h to obtain L-tryptophan fermentation broth;

[0031] Utilize high-speed disc separator to centrifuge L-...

Embodiment 2

[0034] A fermentation process for L-tryptophan, comprising the steps of:

[0035] The tnaA, trpR and tyrR gene knockout or inactivated Escherichia coli ATCC 27325 were cultivated to a concentration of 1×10 7 cfu / mL seed solution, and then inoculate the fermentation medium (glucose 20g / L, corn steep liquor 10g / L, ammonium sulfate 5g / L, dipotassium hydrogen phosphate 2g / L, phosphoric acid Potassium dihydrogen 2g / L, magnesium sulfate 1.5g / L, citric acid 1.5g / L, ferrous sulfate 70mg / L, sodium sulfate 20mg / L, manganese sulfate 7mg / L, zinc sulfate 7mg / L, cobalt chloride 6mg / L, copper sulfate 0.9mg / L), the fermentation temperature is controlled at 36°C, the dissolved oxygen is controlled at 20%, the tank pressure is 0.05MPa, and the residual sugar is controlled at not less than 1.0 by adding a glucose solution with a concentration of 100g / L. %, the pH is controlled at 7 by feeding ammonia water; fermentation is stopped at 30h to obtain L-tryptophan fermentation broth;

[0036] Uti...

Embodiment 3

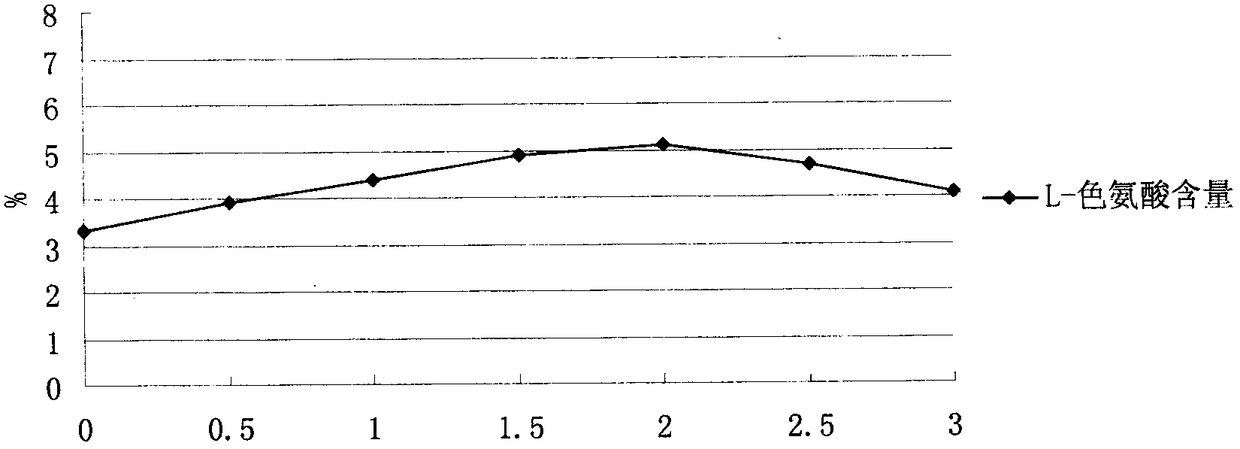

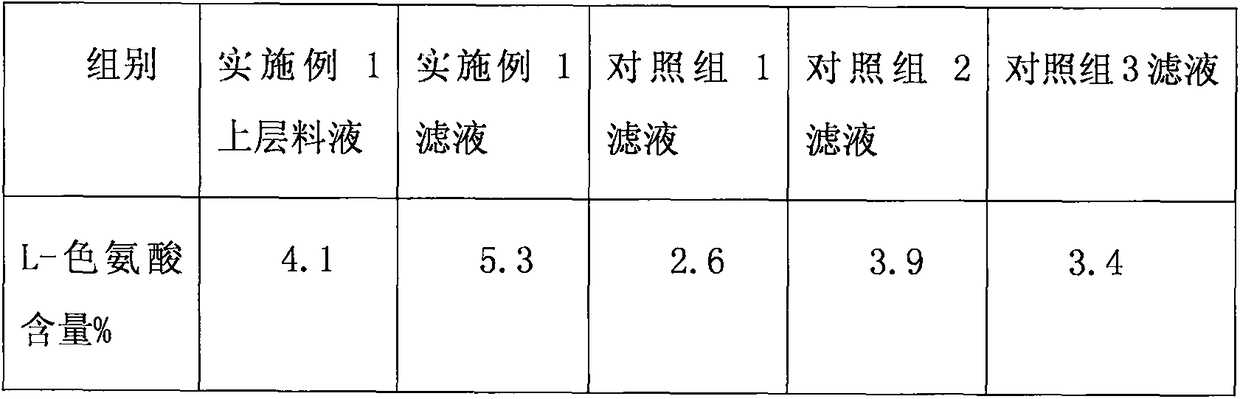

[0039] The impact of various factors on the production of L-tryptophan:

[0040] Taking Example 1 as the test group, the fermentation medium was set to 100 L, and the L-tryptophan output in the upper layer feed liquid and filtrate was detected, and the detection method was determined by HPLC method, specifically referring to the 2007 edition of the British Pharmacopoeia;

[0041] Set control group, wherein, control group 1: control group 1 is: only carry out dialysis culture treatment, do not adopt tourmaline powder and heat treatment, all the other are the same as embodiment 1; Control group 2: after fermentation is finished, carry out tourmaline powder and dialysis culture treatment, No heat treatment, the rest are the same as in Example 1; control group 3: After the fermentation is completed, heat treatment and dialysis culture treatment are carried out, tourmaline powder is not used, the rest is the same as in Example 1; the content of L-tryptophan in the filtrates of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com