Method for improving yield of laccase of Trametes versicolor

A technology of Trametes versicolor and laccase, which is applied in the field of bioengineering, can solve the problems of less research on biological effects, unclear theoretical mechanism of biological effects, etc., and achieves the effects of increasing the yield of laccase, increasing the area, and being easy to enlarge the production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

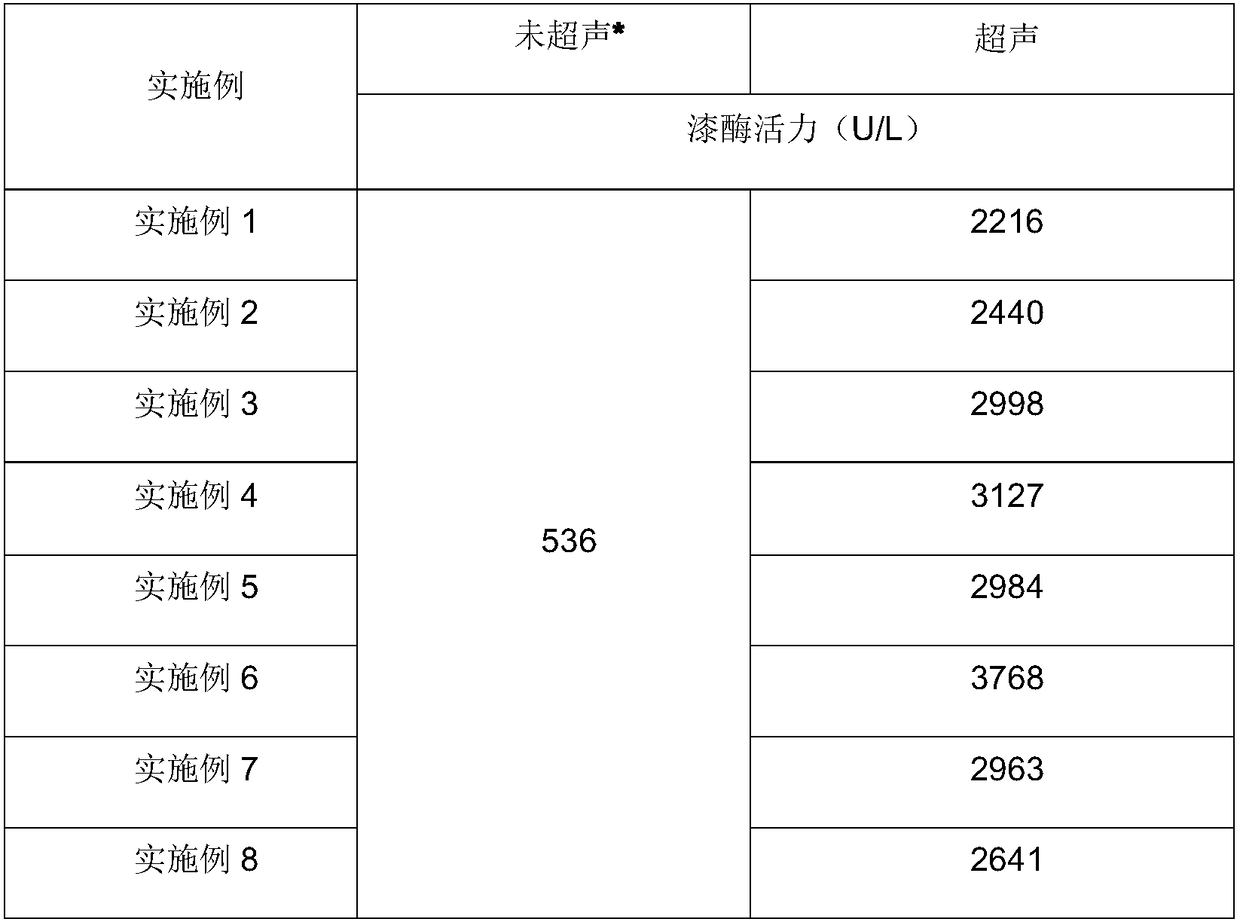

[0031] Embodiment 1: Trametes versicolor laccase fermentation

[0032] (1) Inoculate the pre-cultivated Trametes versicolor mycelium into the laccase fermentation medium with an initial biomass of 10% (v / v) at a temperature of 26°C and 150r / min. fermentation culture;

[0033] (2) During the 6th to 48h of the fermentation process, the bacteria in the triangular flask were ultrasonically treated, the frequency was 45kHz, the ultrasonic power was 120w, and the ultrasonic time was 10s and 10s, 5min, 2 times; 60-120 hours, ultrasonic treatment was performed on the bacteria, the frequency was 20kHz, the power was 150w, and the number of times was 3 times. The rest of the conditions were unchanged, and the cultivation was continued after ultrasonication.

[0034] (3) From the first day to the third day of the fermentation process, adjust the pH to 4.5.

[0035] (4) After 7 days of fermentation and cultivation, the fermentation liquid was collected, and the production of laccase was...

Embodiment 2

[0037] Embodiment 2: Trametes versicolor laccase fermentation

[0038] (1) Inoculate the pre-cultivated Trametes versicolor mycelium into the laccase fermentation medium with an initial biomass of 10% (v / v) at a temperature of 26°C and 150r / min. fermentation culture;

[0039] (2) During the 6th to 48h of the fermentation process, the bacteria in the triangular flask were ultrasonically treated, the frequency was 50kHz, the power was 90w, the time was 10s and 10s, 10min in total, and the ultrasonic frequency was 1 time; ~ 120h, ultrasonic treatment was carried out on the bacteria, the frequency was 28kHz, the power was 120w, the number of ultrasonic waves was 2 times and other conditions remained unchanged, and the cultivation was continued after ultrasonication.

[0040] (3) From the first day to the third day of the fermentation process, adjust the pH to 4.5.

[0041] (4) After 7 days of fermentation and cultivation, the fermentation liquid was collected, and the production...

Embodiment 3

[0044] Embodiment 3: Trametes versicolor laccase fermentation

[0045] (1) Inoculate the pre-cultivated Trametes versicolor mycelium into the laccase fermentation medium with an initial biomass of 10% (v / v) at a temperature of 26°C and 150r / min. fermentation culture;

[0046] (2) During the 6th to 48h of the fermentation process, the bacteria in the triangular flask were ultrasonically treated, the frequency was 60kHz, the power was 60w, the time was 20s and 20s, 20min in total, and the number of ultrasounds was 1 time; ~ 120h, ultrasonic treatment was carried out on the bacteria, the frequency was 28kHz, the power was 120w, the number of ultrasonic waves was 2 times and other conditions remained unchanged, and the cultivation was continued after ultrasonication.

[0047] (3) From the first day to the third day of the fermentation process, adjust the pH to 4.5.

[0048] (4) After 7 days of fermentation and cultivation, the fermentation liquid was collected, and the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com