Three-dimensional electric field and graphene reinforced hollow light-guide fiber photo-catalytic reactor

A technology of photocatalytic reactor and optical fiber, applied in physical/chemical process catalysts, chemical instruments and methods, magnetic/electric field water/sewage treatment, etc., can solve the problem of effective transmission of electron holes and insufficient optical fiber strength, catalyst coating Thickness effect, large light transmission loss and other problems, to achieve the effect of increasing the effective illumination area and photocatalytic reaction area, small reaction specific surface area, and large transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

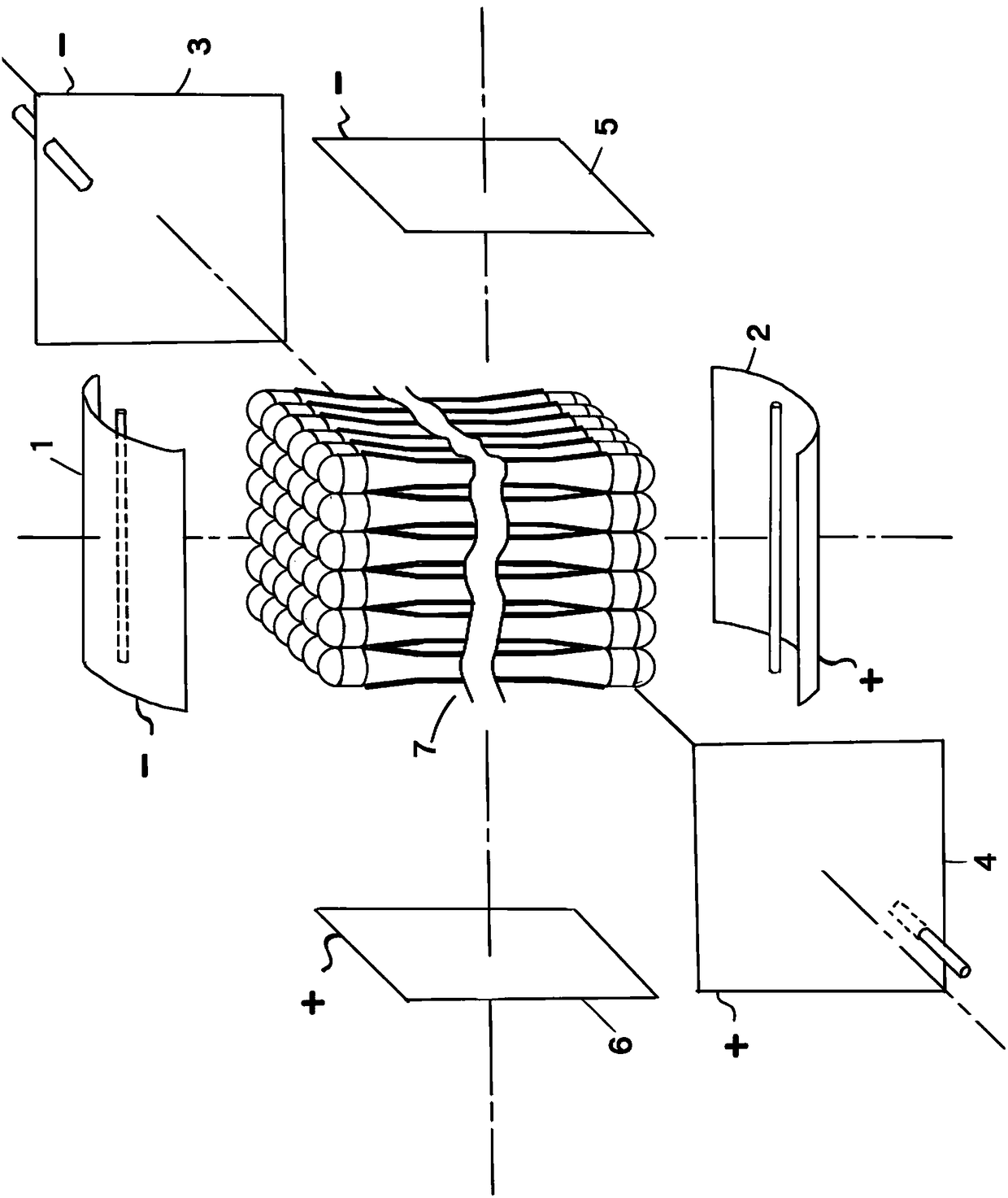

[0016] exist figure 1 Among them, three pairs of electrode plates (1 and 2, 3 and 4, 5 and 6) are placed at positions perpendicular to the three mutually perpendicular symmetry axes, and the pair of electrode plates adjacent to the optical fiber light-introducing end (8) Dome-shaped total reflection mirror metal plates (1 and 2) are used, and ultraviolet lamp tubes are placed at their light reflection focal lengths. The three pairs of electrode plates are alternately fed with low-frequency alternating current below 50 or 60HZ (recommended field strength is 500 to 700 volts), and the power supply is switched to another pair of electrode plates every 0.02 seconds. In the center of the space surrounded by three pairs of electrode plates an assembly (7) is made for a catalyst-coated hollow quartz optical fiber.

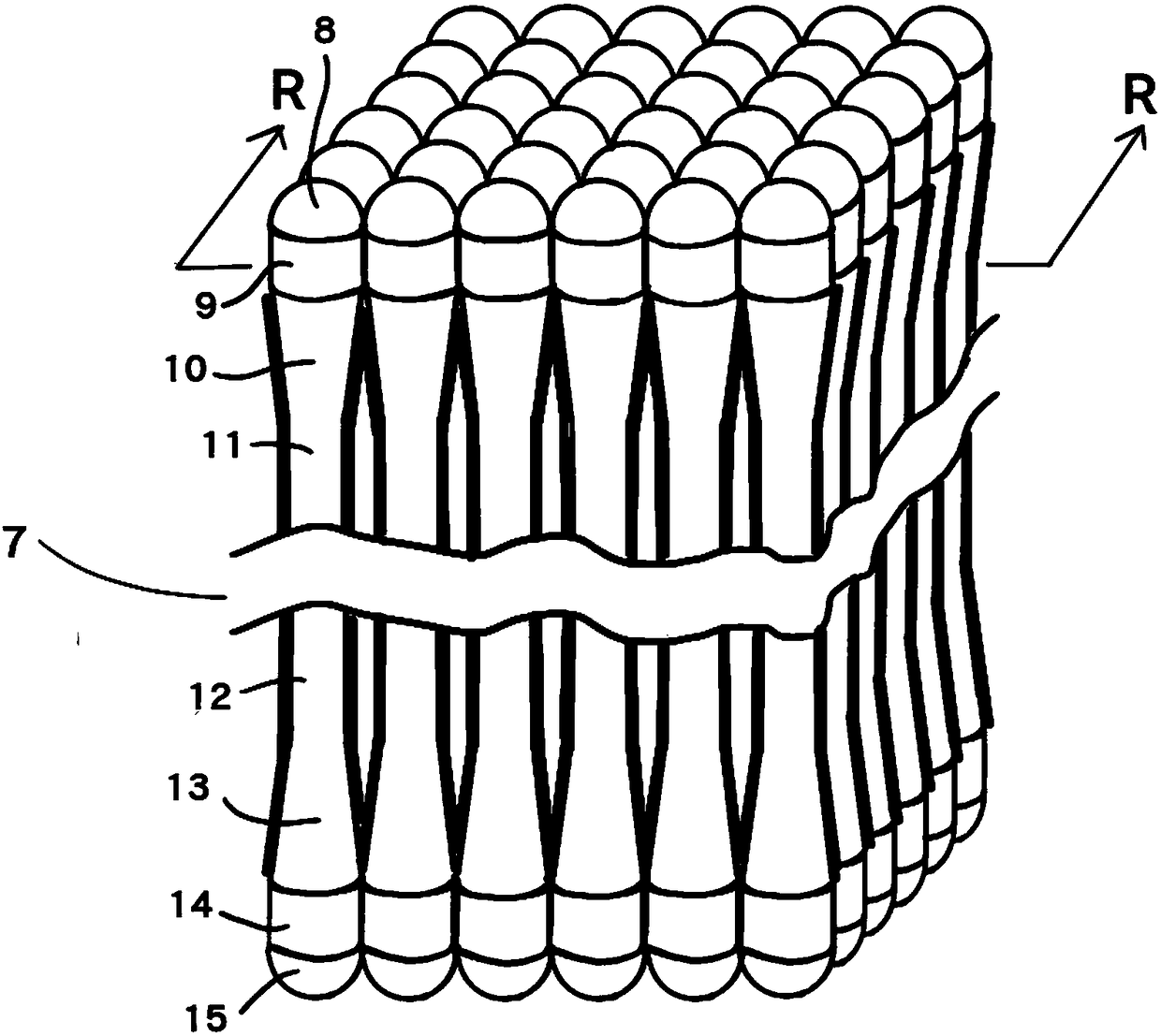

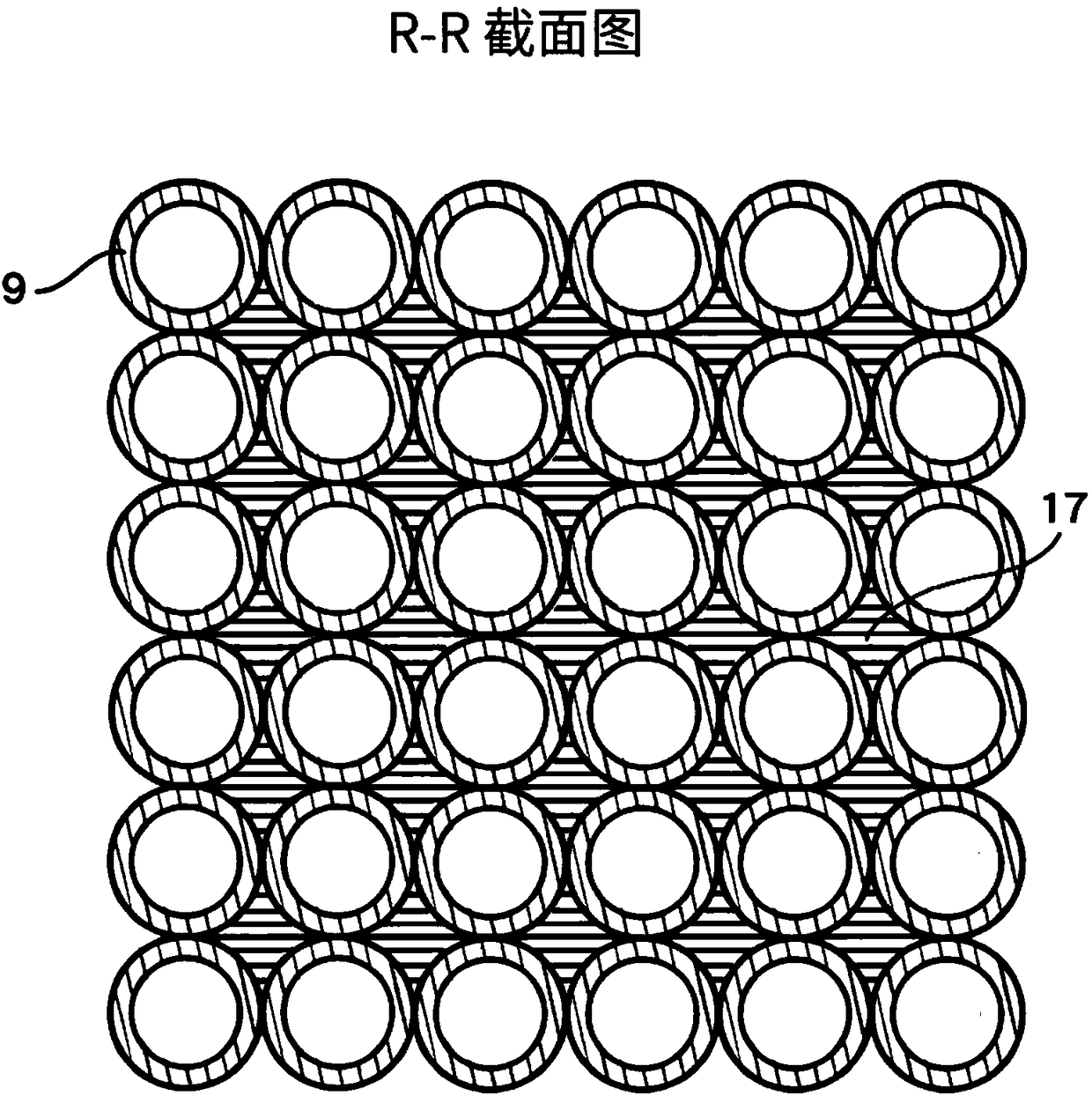

[0017] figure 2 and image 3 respectively figure 1 The enlarged view and R-R cross-sectional view of the hollow quartz optical fiber assembly (7) shown. Figure 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com