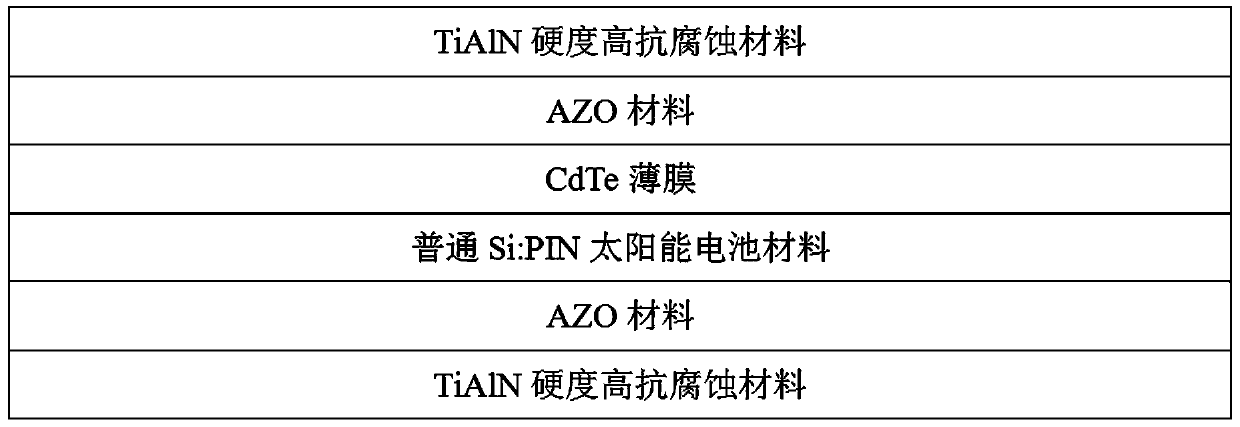

Preparation method for depositing cadmium telluride-based thin-film stacked solar cell material on silicon-based battery plate

A solar cell, cadmium telluride-based technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve problems affecting power generation efficiency, solar cell materials are prone to cracks, etc., to improve photoelectric conversion efficiency and improve photovoltaic conversion Efficiency, the effect of improving the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) The ordinary Si-based solar cell substrate is first ultrasonically cleaned with deionized water for 5 minutes, then blow-dried and sent to the magnetron sputtering reaction chamber. The temperature is 1.0×10 -3 Under Pa vacuum conditions, AZO transparent conductive electrodes were deposited on the back of the battery substrate. The process parameters are as follows: argon and oxygen are used as the mixed gas reaction source, the flow ratio of argon and oxygen is 5:1, the purity of reactive sputtering zinc oxide doped aluminum target is 99.9%, the preparation temperature is 100℃, and the preparation time is 30 minutes.

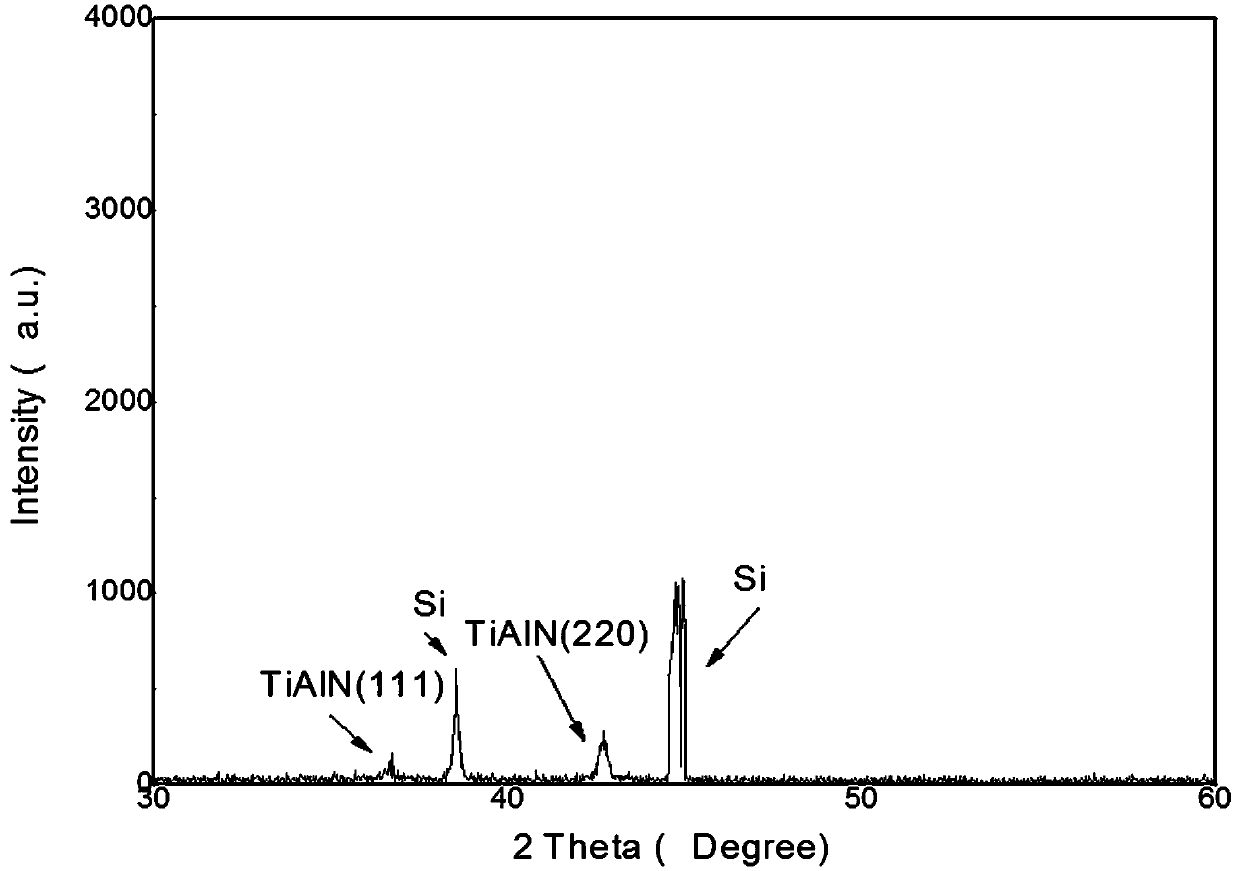

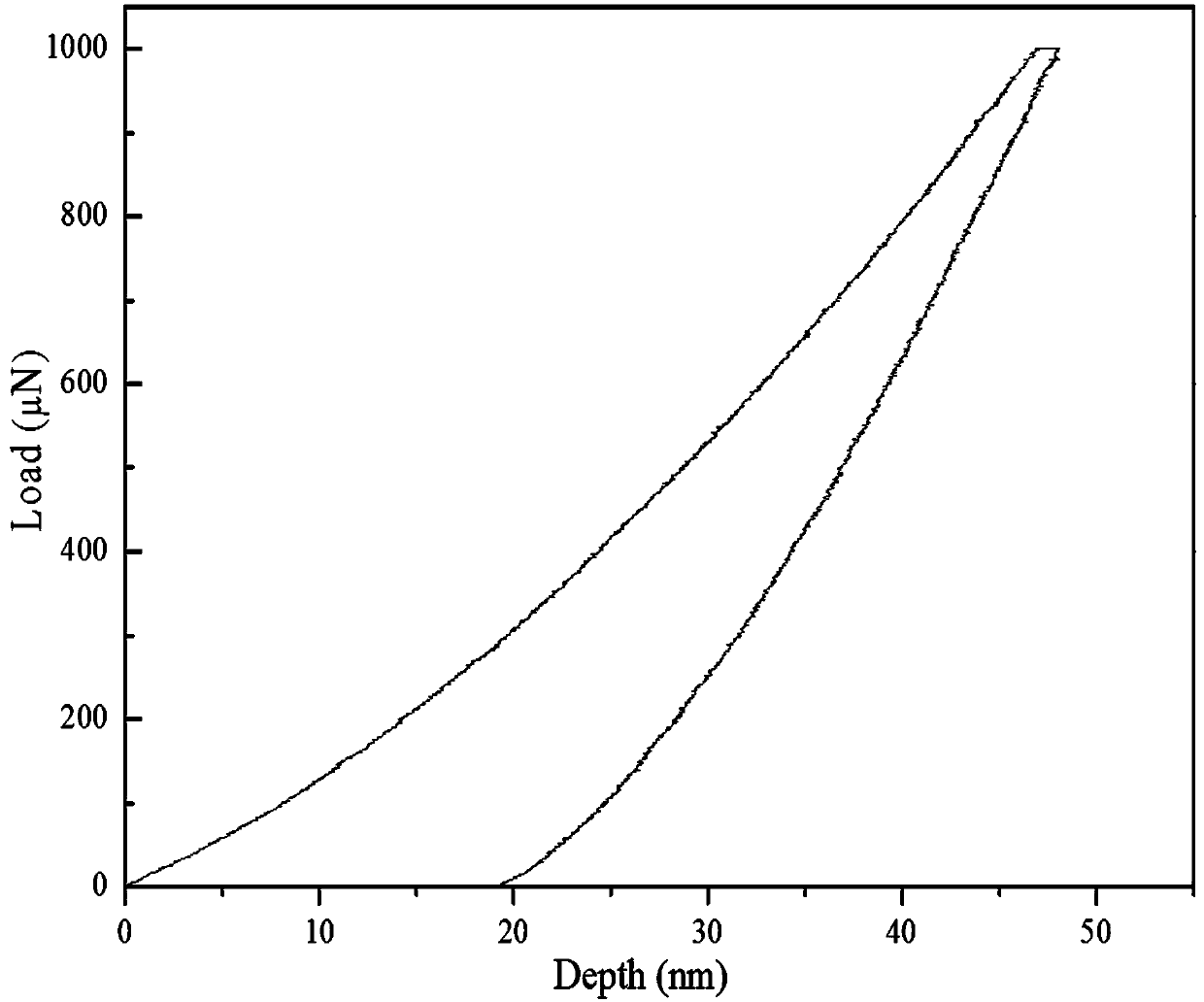

[0061] (2) Continue to prepare TiAlN anti-corrosion protective coating during magnetron sputtering preparation. The process parameters are as follows: nitrogen is used as the gas reaction source, the nitrogen flow is 30 sccm, the purity of the reactive sputtering titanium nitride target and the aluminum target is 99.99%, the preparation temperature is 1...

Embodiment 2

[0066] (1) The ordinary Si-based solar cell substrate is first ultrasonically cleaned with deionized water for 5 minutes, then blow-dried and sent to the magnetron sputtering reaction chamber. The temperature is 1.0×10 -3 Under Pa vacuum conditions, AZO transparent conductive electrodes were deposited on the back of the battery substrate. The process parameters are as follows: argon and oxygen are used as the mixed gas reaction source, the flow ratio of argon and oxygen is 5:1, the purity of reactive sputtering zinc oxide doped aluminum target is 99.9%, the preparation temperature is 150℃, and the preparation time is 30 minutes.

[0067] (2) Continue to prepare TiAlN anti-corrosion protective coating during magnetron sputtering preparation. The process parameters are as follows: nitrogen is used as the gas reaction source, the nitrogen flow is 50 sccm, the purity of the reactive sputtering titanium nitride target and the aluminum target is 99.99%, the preparation temperature is 2...

Embodiment 3

[0072] (1) The ordinary Si-based solar cell substrate is first ultrasonically cleaned with deionized water for 5 minutes, then blow-dried and sent to the magnetron sputtering reaction chamber. The temperature is 1.0×10 -3 Under Pa vacuum conditions, AZO transparent conductive electrodes were deposited on the back of the battery substrate. The process parameter conditions are: argon and oxygen are used as the mixed gas reaction source, the flow ratio of argon and oxygen is 5:1, the purity of reactive sputtering zinc oxide doped aluminum target is 99.9%, the preparation temperature is 200℃, and the preparation time is 30 minutes.

[0073] (2) Continue to prepare TiAlN anti-corrosion protective coating during magnetron sputtering preparation. The process parameter conditions are: nitrogen is used as the gas reaction source, the nitrogen flow is 70 sccm, the purity of the reactive sputtering titanium nitride target and the aluminum target is 99.99%, the preparation temperature is 350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com