Reciprocating guiding rail dual-port cylinder engine

A technology of engines and guide rails, which is applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of low thermal efficiency, complex structure, and high failure rate of engines, and achieve the effects of improved thermal efficiency, small size, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

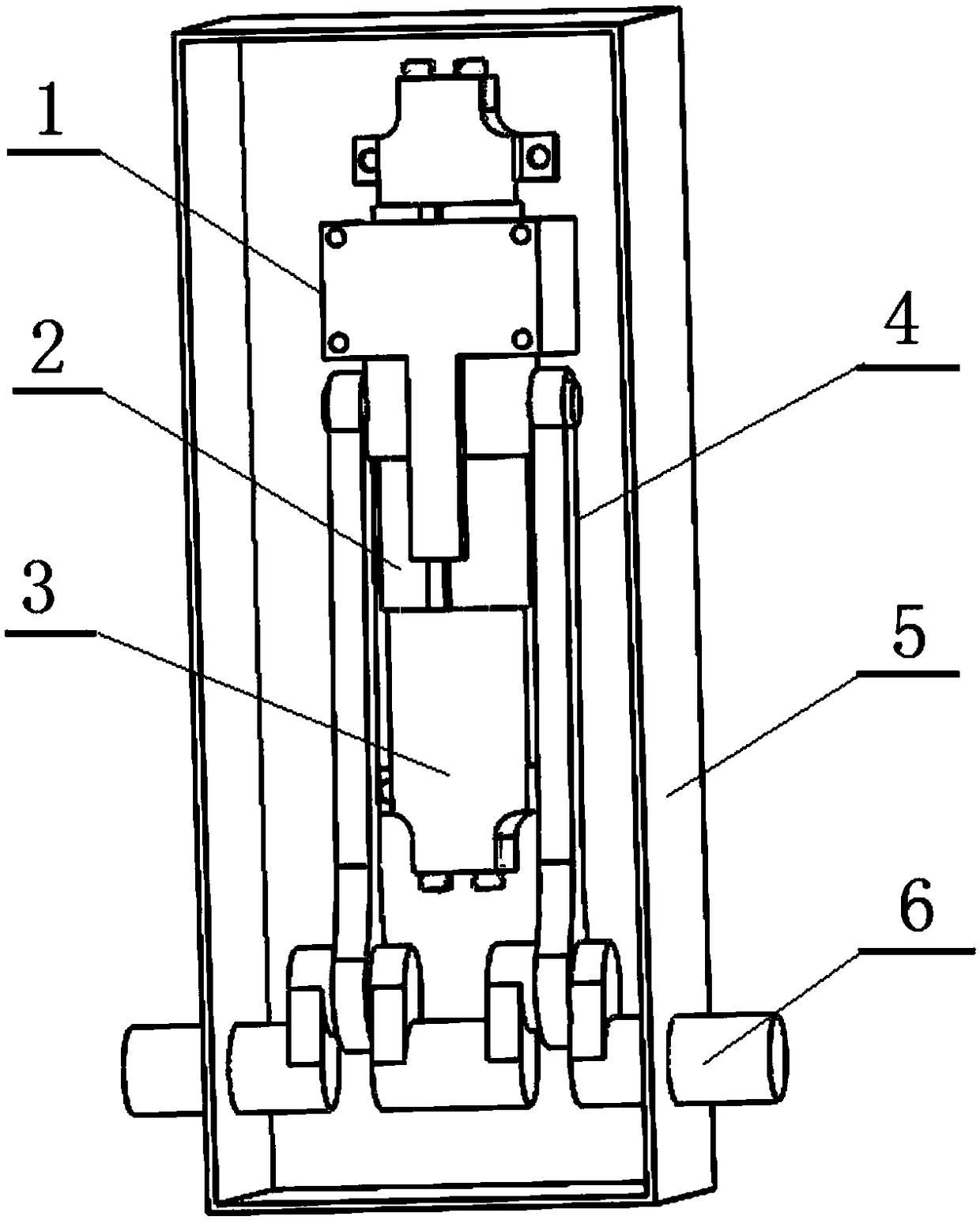

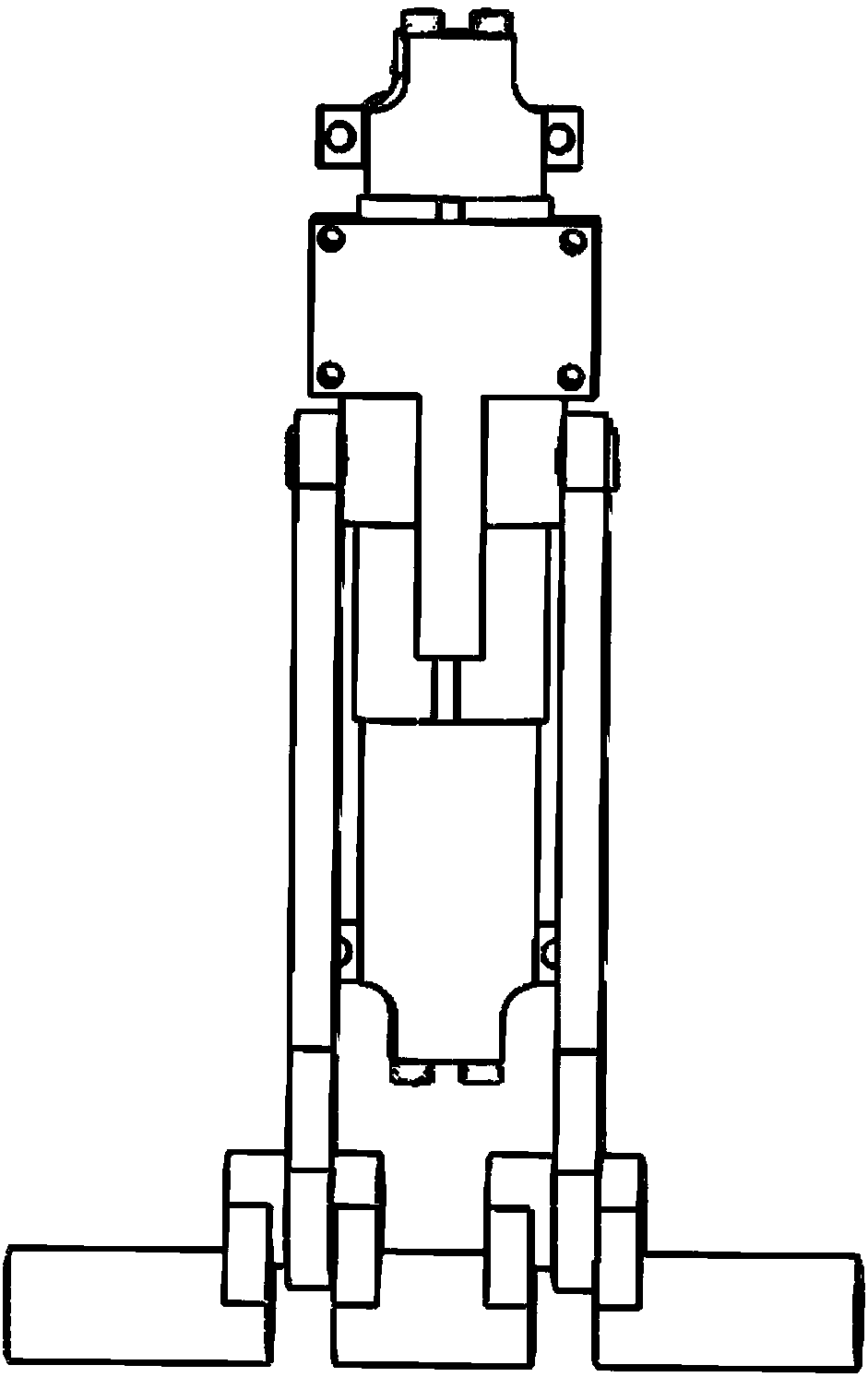

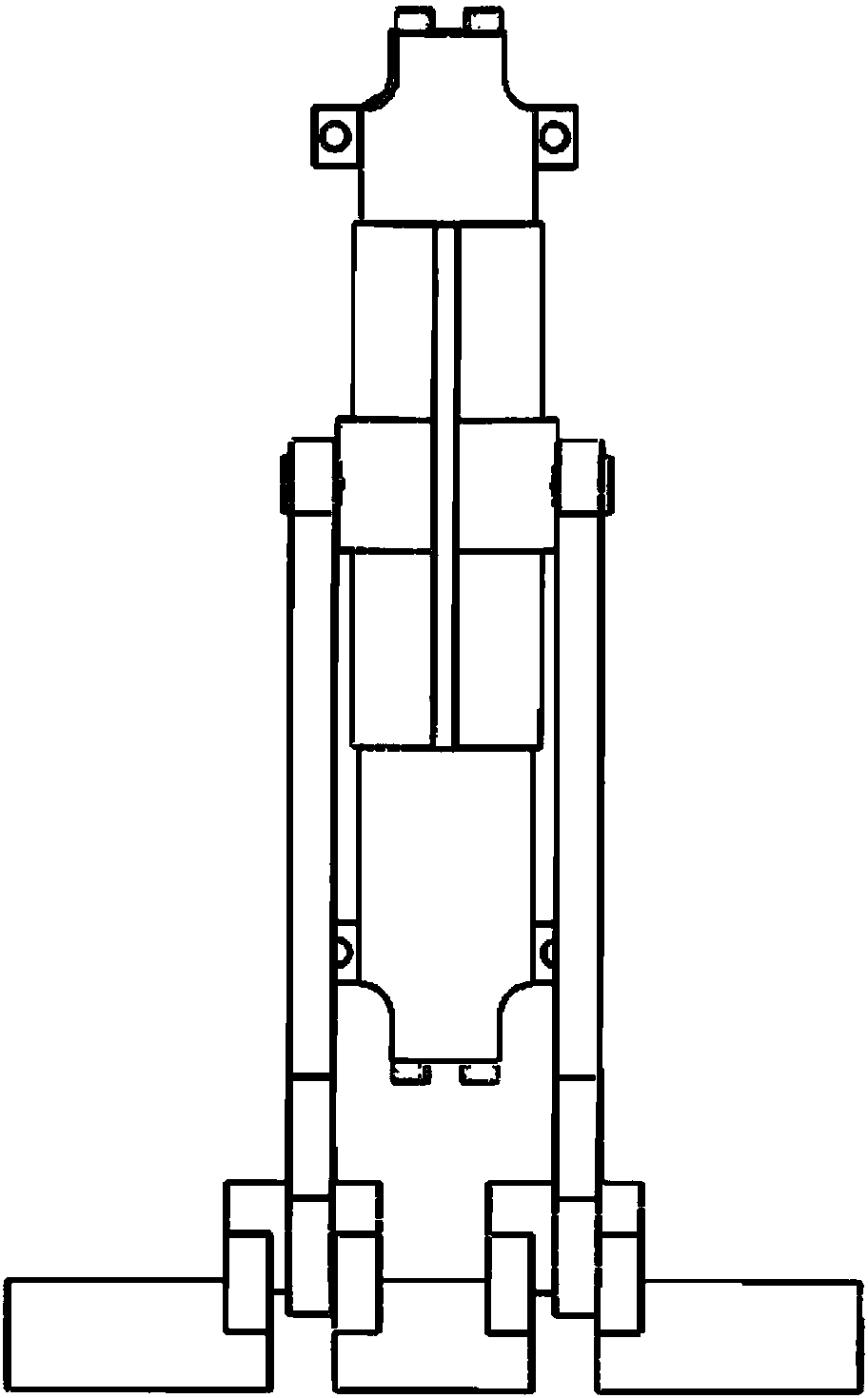

[0052]As shown in the accompanying drawings, the reciprocating guide rail double-port cylinder engine of the present invention includes a guide rail support 1, a guide rail double port cylinder 2, a plunger 3, a crankshaft 6 and a casing 5; the guide rail support 1 is fixed on the casing 5 , the guide rail double-port cylinder 2 is closed in the middle and open at both ends, and the two ends of the guide rail double-port cylinder 2 openings are respectively socketed with a plunger 3; Ring 37, an intake valve 32, an exhaust valve 31 and a fuel injection nozzle 33 are provided on the top of one end of the sealing ring 37, and an intake pipe 34, an exhaust pipe 36 and a cooling pipe 35 are provided at the other end of the plunger 3 The crankshaft 6 is installed in the lower part of the casing, and is connected with the guide rail double-port cylinder 2 through the connecting rod 4, the cylinder body of the guide rail double-port cylinder 2 is provided with a linear guide rail ridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com