Burner for growing crystals by flame fusion method

A technology for growing crystals and burners, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of increasing crystal oxygen vacancies, uneven crystal composition, and high local temperature, to improve size and uniformity, reduce Crystal oxygen vacancies and the effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

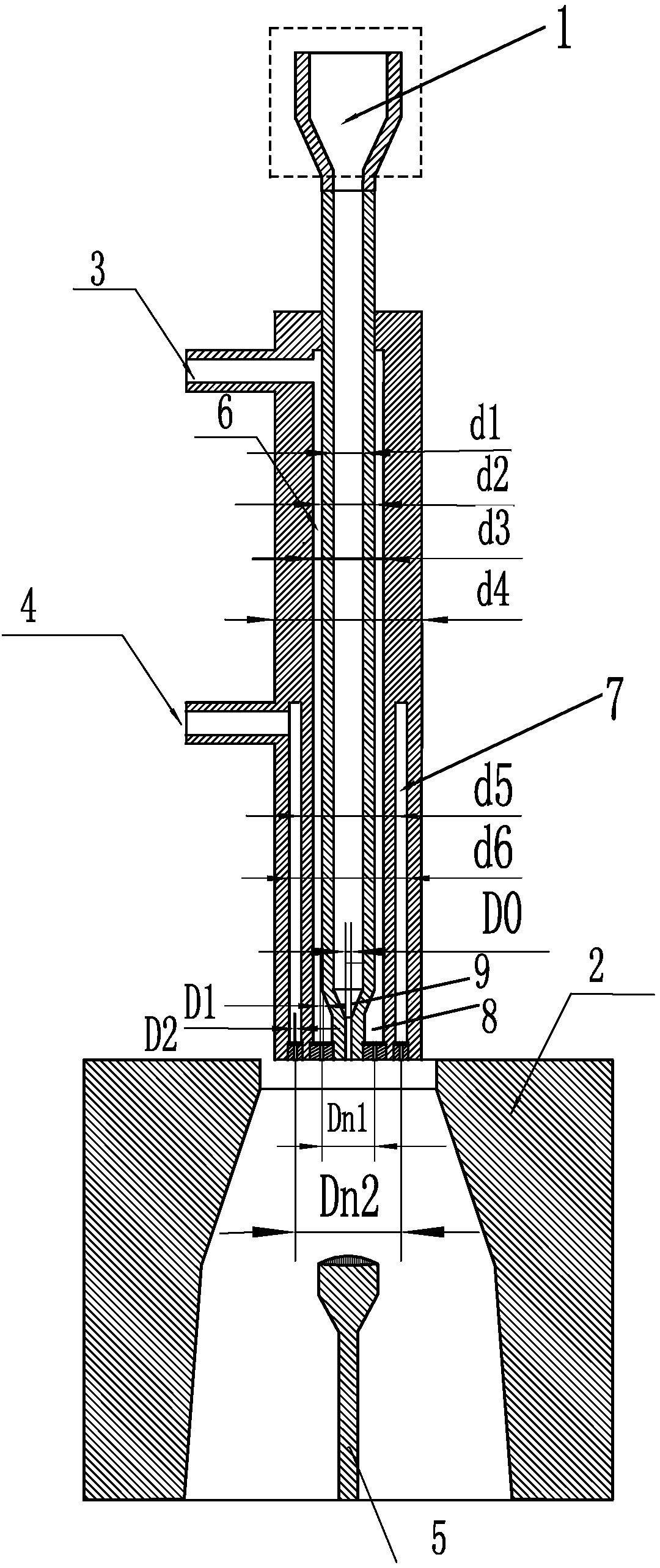

[0025] Embodiment 1, a kind of burner of growing crystal by flame melting method, see figure 1 In this embodiment, the burner is located in the middle of the three-stage frustum-shaped structure, and has a cylindrical structure as a whole, including: a conical feeding port 1, a central pipe, a hydrogen inlet 3, an external oxygen inlet 4, a hydrogen annular pipeline 6, and an external oxygen annular Pipeline 7, crystal growth chamber 2 and crystal growth base 5, the tapered feeding port 1 is connected to the central tube, powder and oxygen are fed into the central tube from the tapered feeding port 1, and a hydrogen annular pipeline is arranged outside the central tube 6. The hydrogen ring pipeline 6 is filled with hydrogen through the hydrogen gas inlet 3 connected to it, and the outer oxygen ring pipeline 7 is arranged outside the hydrogen gas ring pipeline 6, and the outer oxygen ring pipeline 7 is filled with oxygen through the external oxygen inlet 4 connected thereto. , ...

Embodiment 2

[0031] Embodiment 2, differs from Embodiment 1 of the present invention in that: wherein: the inner diameter d1 of the central tube is 8.2mm, the inner diameter d2 of the hydrogen annular pipeline is 21.5mm, the outer diameter d3 of the hydrogen annular pipeline is 36mm, and the outer oxygen annular The inner diameter d5 of the pipeline is 38mm, the outer diameter d6 of the external oxygen annular pipeline is 43mm, the outer wall diameter d4 of the burner is 54.3mm, the diameter D0 of the central tube nozzle is 3.5mm, and the diameter D0 of the central tube nozzle is determined according to the crystal to be prepared. The hydrogen annular pipeline nozzle is 12 circular holes with equal diameters, and the centers of the 12 circular holes are connected to each other to form a hydrogen annular pipeline nozzle distribution circle. The hole diameter D1 is 2mm, and the nozzle of the external oxygen annular pipeline is 12 circular holes with equal diameters, the centers of the 12 circ...

Embodiment 3

[0033] Embodiment 3 is different from Embodiment 1 of the present invention in that: the inner diameter d1 of the central tube is 6mm, the inner diameter d2 of the hydrogen annular pipeline is 14mm, the outer diameter d3 of the hydrogen annular pipeline is 23mm, and the inner diameter d5 of the outer oxygen annular pipeline The outer diameter d6 of the external oxygen annular pipe is 36mm, the outer wall diameter d4 of the burner is 48mm, the diameter D0 of the central tube nozzle is 3.0mm, and the diameter D0 of the central tube nozzle is determined according to the crystal to be prepared. The hydrogen annular pipeline nozzle is 15 circular holes with equal diameters, and the centers of the 15 circular holes are connected to each other to form a hydrogen annular pipeline nozzle distribution circle. The hole diameter D1 is 0.5mm, and the nozzle of the external oxygen annular pipeline is 15 circular holes with equal diameters. The centers of the 15 circular holes are connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com