Drawing oil

A wire drawing oil and base oil technology, applied in the field of lubricating oil, can solve the problems that wire drawing oil is not easy to biodegrade, difficult to achieve lubricating effect, poor environmental friendliness, etc., to achieve enhanced anti-oxidation performance and stability, lower friction coefficient, easy The effect of protective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

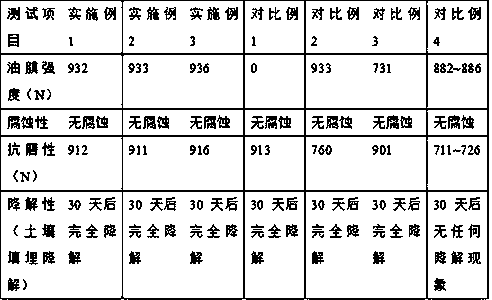

Examples

Embodiment 1

[0032] Long handle almond oil: purchased from a biotechnology company in Yulin, Shaanxi.

[0033] Pectin: purchased from Zhengzhou Yizhiyuan Chemical Products Co., Ltd.

[0034] Drawing oil base oil: A. Take almond oil and palm oil in a mass ratio of 2:1:10, add methanol and mix, stir and mix at 55°C for 50 minutes, then add sulfuric acid with a mass fraction of 1% of methanol and 80%, and stir Mix for 2 hours, cool to room temperature, let stand to separate layers, and collect the upper layer;

[0035] B. Take the supernatant liquid and mix it with glacial acetic acid according to the mass ratio of 20:3, stir and mix at 30°C for 50 minutes to obtain the mixture, take the mixture according to the mass ratio of 80:90:1, add hydrogen peroxide and sulfuric acid with a mass fraction of 80%, and heat it at 60°C Stir and mix for 5 hours, let stand for 10 hours, take the supernatant, wash with a sodium carbonate solution with a mass fraction of 0.8%, and a sodium chloride solution w...

Embodiment 2

[0043] Long handle almond oil: purchased from a biotechnology company in Yulin, Shaanxi.

[0044] Pectin: purchased from Zhengzhou Yizhiyuan Chemical Products Co., Ltd.

[0045] Drawing oil base oil: A. Take almond oil and palm oil in a mass ratio of 2:1:10, add methanol and mix, stir and mix at 60°C for 60 minutes, then add 80% sulfuric acid with a mass fraction of 2% of methanol, and stir Mix for 3 hours, cool to room temperature, let stand to separate layers, and collect the upper layer;

[0046] B. Take the supernatant liquid and mix it with glacial acetic acid at a mass ratio of 20:3, stir and mix at 40°C for 60 minutes to obtain a mixture, take the mixture at a mass ratio of 90:100:1, add hydrogen peroxide and sulfuric acid with a mass fraction of 80%, and heat it at 65°C Stir and mix for 6 hours, let stand for 12 hours, take the supernatant, wash with a sodium carbonate solution with a mass fraction of 0.8%, and a sodium chloride solution with a mass fraction of 26%, a...

Embodiment 3

[0054] Long handle almond oil: purchased from a biotechnology company in Yulin, Shaanxi.

[0055] Pectin: purchased from Zhengzhou Yizhiyuan Chemical Products Co., Ltd.

[0056] Drawing oil base oil: A. Take almond oil and palm oil in a mass ratio of 2:1:10, add methanol and mix, stir and mix at 57°C for 55 minutes, then add sulfuric acid with a mass fraction of 1% of methanol and 80% by mass, and stir Mix for 2 hours, cool to room temperature, let stand to separate layers, and collect the upper layer;

[0057] B. Take the supernatant liquid and mix it with glacial acetic acid according to the mass ratio of 20:3, stir and mix at 35°C for 55 minutes to obtain the mixture, take the mixture according to the mass ratio of 85:95:1, add hydrogen peroxide and sulfuric acid with a mass fraction of 80%, and heat it at 63°C Stir and mix for 5 hours, let stand for 11 hours, take the supernatant, wash with a sodium carbonate solution with a mass fraction of 0.8%, and a sodium chloride so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com