Plated film paint system, plastic part with metal effect coating, and preparation method of plated film paint system

A technology for plastic parts and coatings, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, and achieve the effect of enhanced adhesion, improved metal texture, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The above-mentioned preparation process of plastic parts with metal effect coating combines the coating obtained by the physical vapor deposition method with the color paint effect and laser engraving technology to form a new surface treatment process, which can produce imitation anodic oxidation and high-quality metal effects Combined plastic parts, among which, the transparent UV medium paint layer adopts high molecular weight hydroxy acrylic resin to achieve good adhesion between layers. At the same time, the present invention performs radium engraving after all the coatings are painted. Compared with the process in the prior art where the color paint layer and the coating are engraved with radium and then the topcoat is sprayed, the process flow is simplified and the production efficiency is improved.

[0044] Preferably, the viscosity of the transparent UV primer in step (1) is 8.0-9.5s, the leveling time is 5-8min, the baking temperature is 50-60°C, and the UV curi...

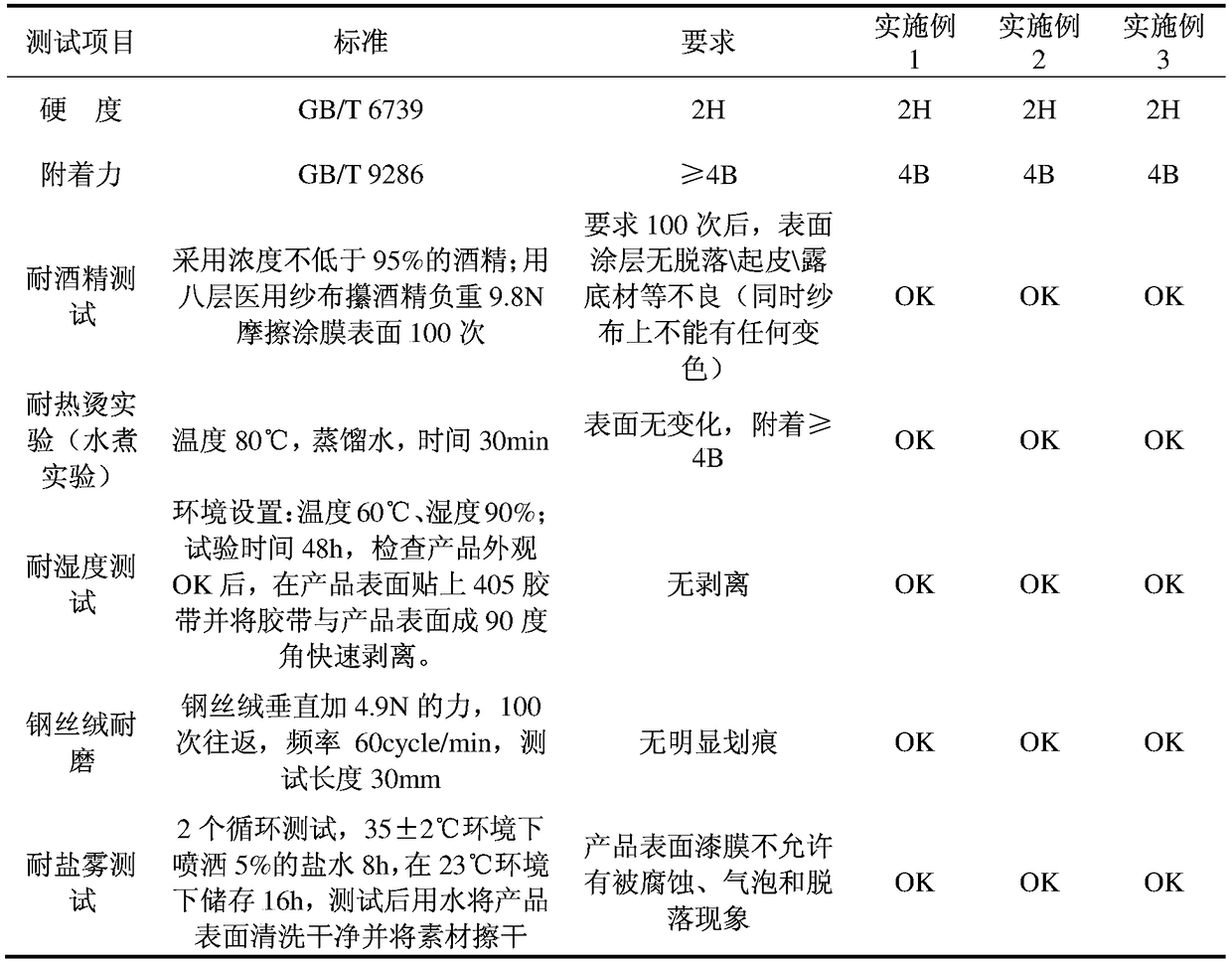

Embodiment 1

[0052] The film-coating paint system of present preferred embodiment comprises transparent UV primer, be coated on the transparent UV intermediate paint on the plated layer, color paint and transparent UV topcoat; Transparent UV primer comprises the polyurethane acrylic acid of 60% by weight percentage ester, 19% ethyl acetate, 19% butyl acetate, 2% additives; the coating adopts indium with a purity of 99.9%, and the quality of indium used is 4.0g; the transparent UV intermediate paint includes 50% polyurethane acrylate, 5% hydroxy acrylic resin, 20% ethyl acetate, 10% butyl acetate, 12% diisobutyl ketone, 3% additives, the molecular weight of hydroxy acrylic resin is greater than 50,000; The color paint comprises 40% fluorine-modified hydroxyacrylic resin, 10% thermoplastic acrylic resin (the molecular weight of thermoplastic acrylic resin is 150000), 5% metallic aluminum pigment, 5% mica powder, 5% Color paste, 13% butyl acetate, 20% ethyl acetate, 2% additives. The color p...

Embodiment 2

[0065] The film-coating coating system of present preferred embodiment comprises transparent UV primer, be coated on the transparent UV intermediate paint on the plated layer, color paint and transparent UV topcoat; Transparent UV primer comprises the polyurethane acrylic acid of 57% by weight percentage Ester, 20% ethyl acetate, 20% butyl acetate, 3% additives; the coating is made of aluminum, and the quality of the aluminum used is 5.0g;

[0066] The transparent UV intermediate paint comprises 50% polyurethane acrylate, 10% hydroxyl acrylic resin, 17% ethyl acetate, 10% butyl acetate, 10% diisobutyl ketone, 3% additives, the molecular weight of hydroxyacrylic resin is greater than 50000;

[0067] The color paint comprises 20% fluorine-modified hydroxyacrylic resin, 20% thermoplastic acrylic resin (molecular weight 200000 of thermoplastic acrylic resin), 5% metallic aluminum pigment, 5% mica powder, 5% Color paste, 23% butyl acetate, 20% ethyl acetate, 2% additives. The col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com