Tubular material with X ray developing function, and preparation method thereof

An X-ray and tube technology, used in the medical field, can solve the problems of material performance decline and poor surface smoothness of medical catheters, and achieve excellent performance, excellent internal and external surface quality and smooth effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

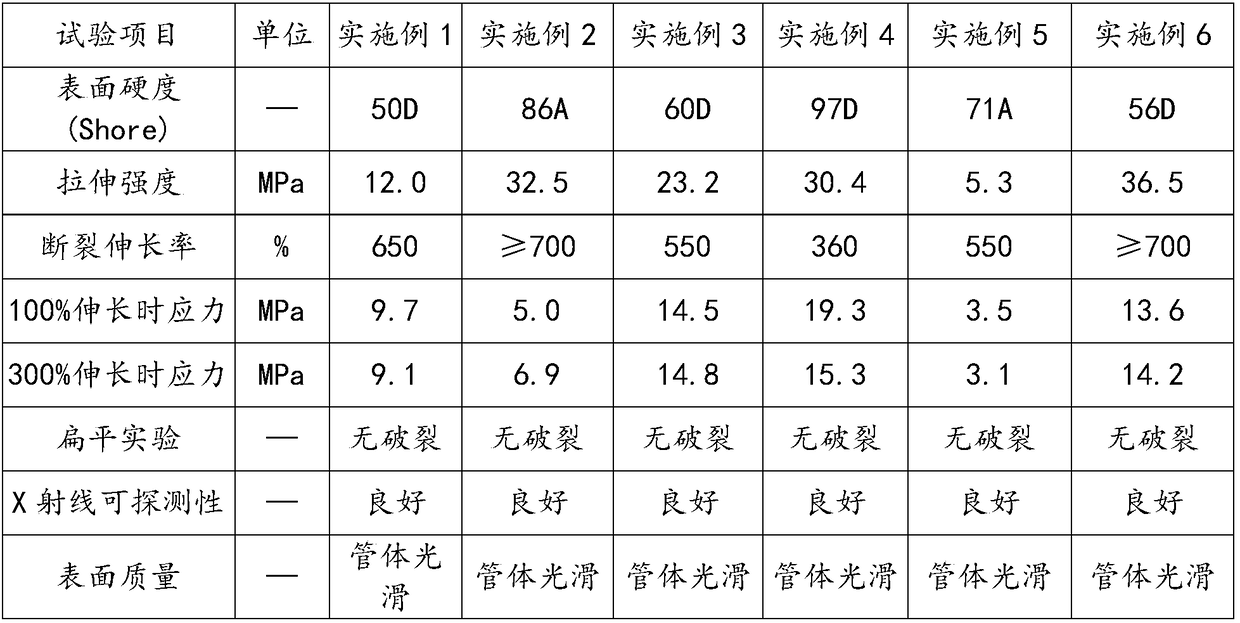

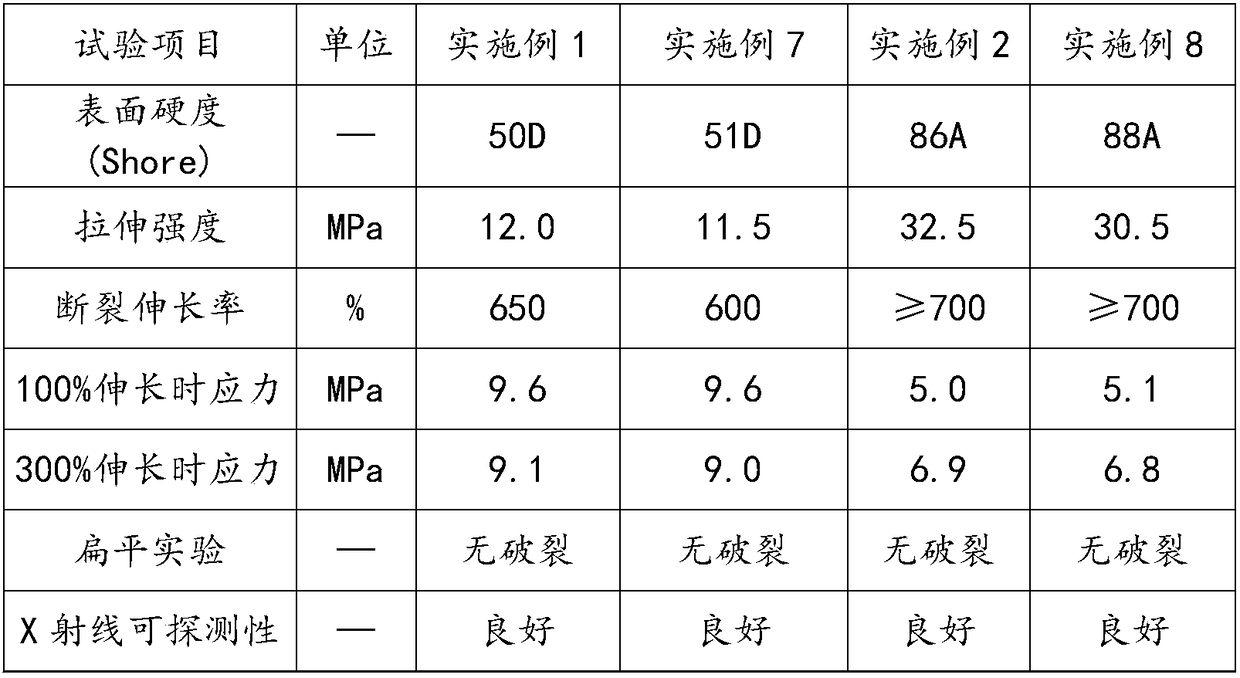

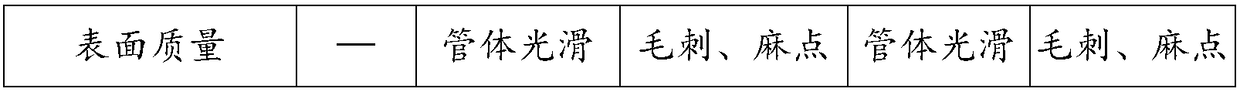

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides a method for preparing the above-mentioned tube with X-ray imaging function, which includes the following steps:

[0035] 1. Add 34.2-60.2% of base resin, 39-65% of developer, 0.1-0.5% of antioxidant, 0.1-0.4% of dispersant, 0.1-0.3% of internal lubricant, and 0.1-0.3% of external lubricant into high-speed mixing In the machine, mix for 3-5 minutes;

[0036] 2. Add the mixed materials into a twin-screw extruder for melt blending, extrusion and granulation to obtain a medical catheter composite material with an X-ray imaging function with a developer weight content of 39-65%. Wherein, the temperature of each working section of the twin-screw extruder is set according to the melting point or melting temperature of the base resin;

[0037] 3. Use two single-screw extruders to form a composite extruder, and extrude with a co-extrusion head to obtain a pipe with a three-layer structure.

[0038] 3.1 sending the composit...

Embodiment 1

[0043] This embodiment provides a low-density polyethylene composite pipe with X-ray imaging function, and its raw material composition and preparation method are as follows:

[0044] 1. Low-density polyethylene 60.2%, bismuth trioxide 39%, antioxidant 1010 0.15%, antioxidant 1680.15%, diffusing agent EBS 0.2%, zinc stearate 0.15% and polyethylene wax 0.15%; In a high-speed mixer, dry mix for 5 minutes to obtain a mixed material.

[0045] 2. Add the mixed materials into a twin-screw extruder for melt blending, extrusion and granulation to obtain a low-density polyethylene composite material for the core layer. Among them, the temperature of each section of the twin-screw extruder starts from the feeding port and is set to 125°C, 170°C, 185°C, 190°C, 190°C, 190°C, 190°C, 190°C, 190°C, 190°C. The temperature was set to 185°C.

[0046] 3. Use two single-screw extruders to extrude the low-density polyethylene composite material for the core layer and the low-density polyethylene...

Embodiment 2

[0050] This embodiment provides a TPU composite pipe with X-ray imaging function, its raw material composition and preparation method are as follows:

[0051] 1. Polyurethane thermoplastic elastomer (TPU) 49.3% (the TPU is specifically Estane58315 provided by Lubrizol), barium sulfate 50%, antioxidant 1010 0.15%, diffusing agent EBS 0.25%, zinc stearate 0.15%, polyethylene Wax 0.15%; in a high-speed mixer, dry blend for 5 minutes to obtain a mixed material.

[0052] 2. Add the mixed materials into a twin-screw extruder for melt blending, extrusion and granulation to obtain a low-density polyethylene composite material for the core layer. Among them, the temperature of each section of the twin-screw extruder starts from the feeding port, and is set to 125°C, 170°C, 180°C, 185°C, 185°C, 185°C, 185°C, 185°C, 190°C, 190°C. The temperature was set to 185°C.

[0053] 3. Extrude the TPU composite material for the core layer and the TPU base resin with two single-screw extruders, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com